Surface hole structure in dam body of high concrete dam

A technology of concrete dams and surface holes, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as difficult to achieve results, achieve good adaptability, improve energy dissipation rate, and increase shear area effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

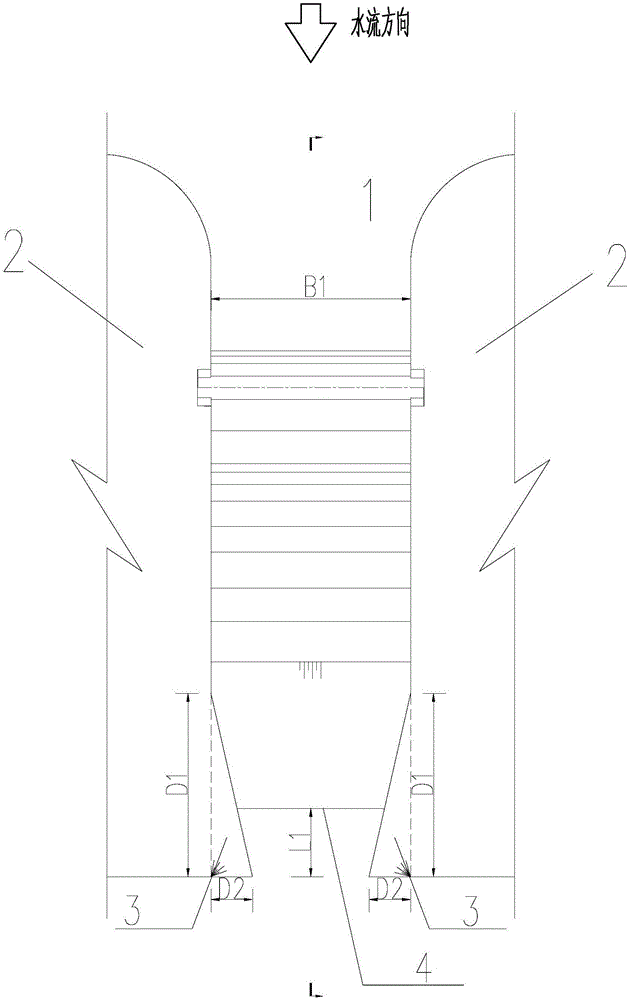

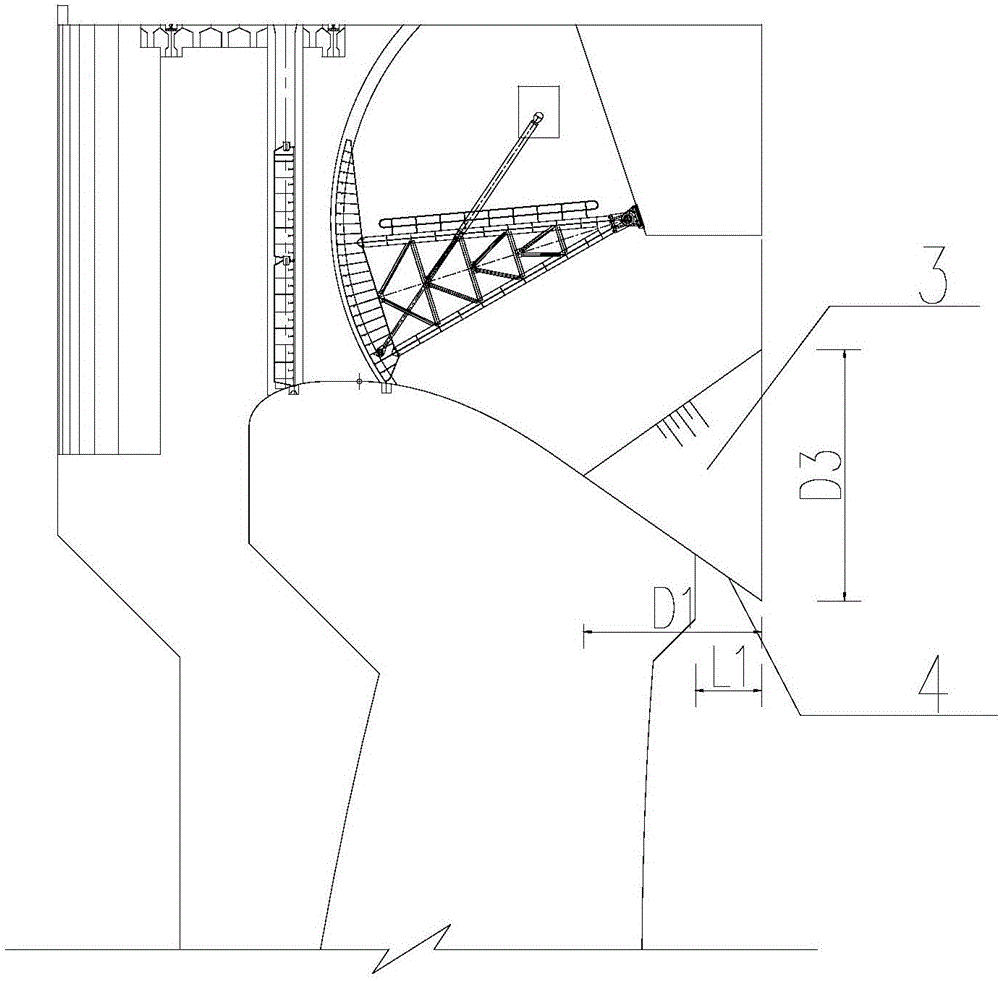

[0014] Such as figure 1 , figure 2 Shown, the surface hole structure of the dam body of the high concrete dam of the present embodiment includes the surface hole 1 with the flood discharge function of the dam body, the entrance width of the surface hole 1 is B1=12m, and there are side walls 2 on both sides of the surface hole 1. A wedge-shaped body 3 with a length D1=13m, a width D2=3m, and a height D3=12m is arranged symmetrically on the side wall near the outlet of the flow channel, and the two wedge-shaped bodies 3 are gathered in the middle, so that the water tongue from the surface hole can go downstream along the river channel Pull it apart vertically and pull it up. At the same time, by setting a hollow 4 with a length of L1 at the outlet end of the flow channel bottom plate of the surface hole 1, the outlet tongue of the surface hole is further pulled longitudinally to the upstream of the water cushion pond or the stilling pond, and the water cushion pond or the stil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com