Grinding medium

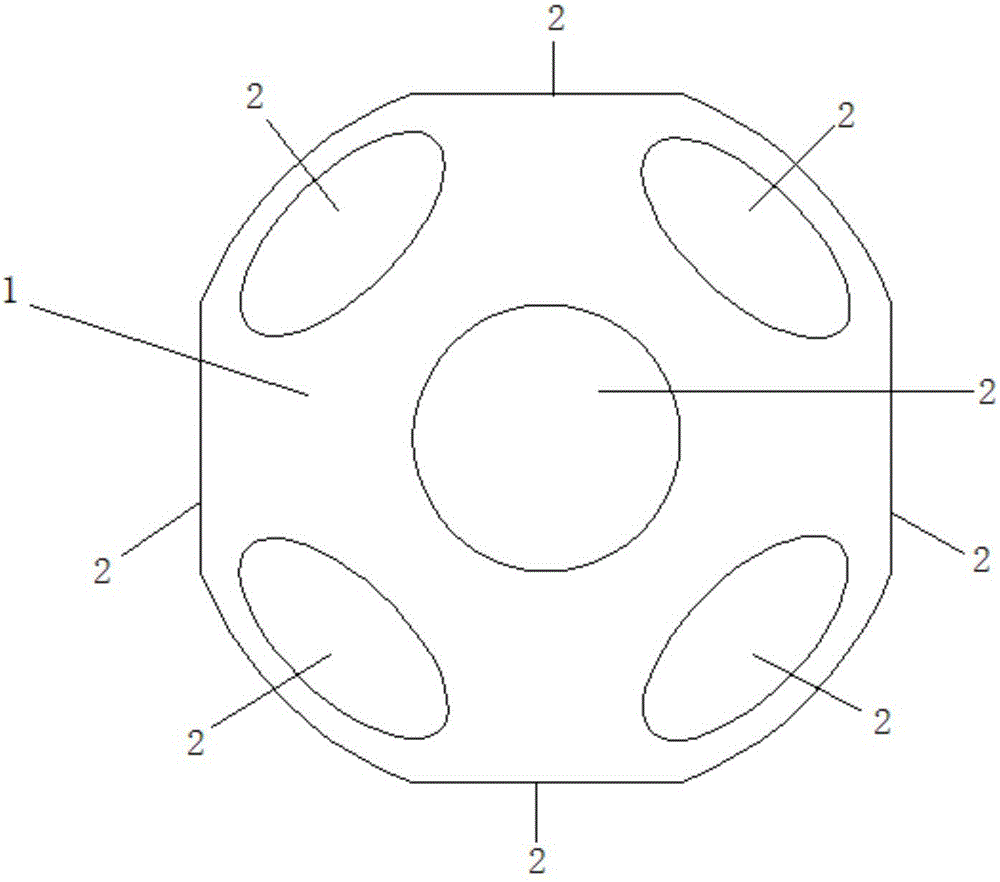

A technology of grinding media and spheres, which is applied in the field of grinding materials, can solve problems such as rarely used, and achieve the effect of improving grinding efficiency and increasing shear area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Making Grinding Media by Injection Molding

[0027] Use 3 moles of yttrium oxide zirconium produced by Hubei Xitian Technology Co., Ltd., and mix according to the ratio of powder: glue = 80:20. After mixing evenly, extrude it into a 5mm grinding medium mold through a screw extruder to form, and demould After dewaxing, finally calcined at 1450°C for 3 hours to obtain 5mm football-shaped zirconia balls.

Embodiment 2

[0029] Making Grinding Media by Casting

[0030] Configure the gel component according to the mass ratio of water: polyacrylamine: N'N-methylenebisacrylamide = 120:15:1, and adjust the pH to 9.6. After stirring for 30 minutes, the solid content is 50%. Add 3 moles of yttrium zirconium oxide produced by Hubei Xitian Technology Co., Ltd., grind and disperse, add 3 / 1000 ammonium persulfate and a few drops of n-butanol, discharge while ball milling, inject into a 5mm mold and heat to 60°C After heat preservation for 20 minutes, the mold was removed, dried in the shade for 48 hours, and then calcined at 1450° C. for 3 hours to obtain 5 mm football-shaped zirconia balls.

[0031] The grinding media produced by the present invention can be used in roller mills, stirring mills, planetary mills, basket mills, sand mills and other mills as grinding media for grinding dispersed materials. Compared with traditional grinding media, the grinding media of the invention has high and uniform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com