Low-breaking rate egg collecting device for poultry breeding

A breaking rate and egg collection technology, applied in poultry cages or houses, applications, poultry industry, etc., can solve the problems of low breaking rate, egg breaking, easy to trample eggs and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

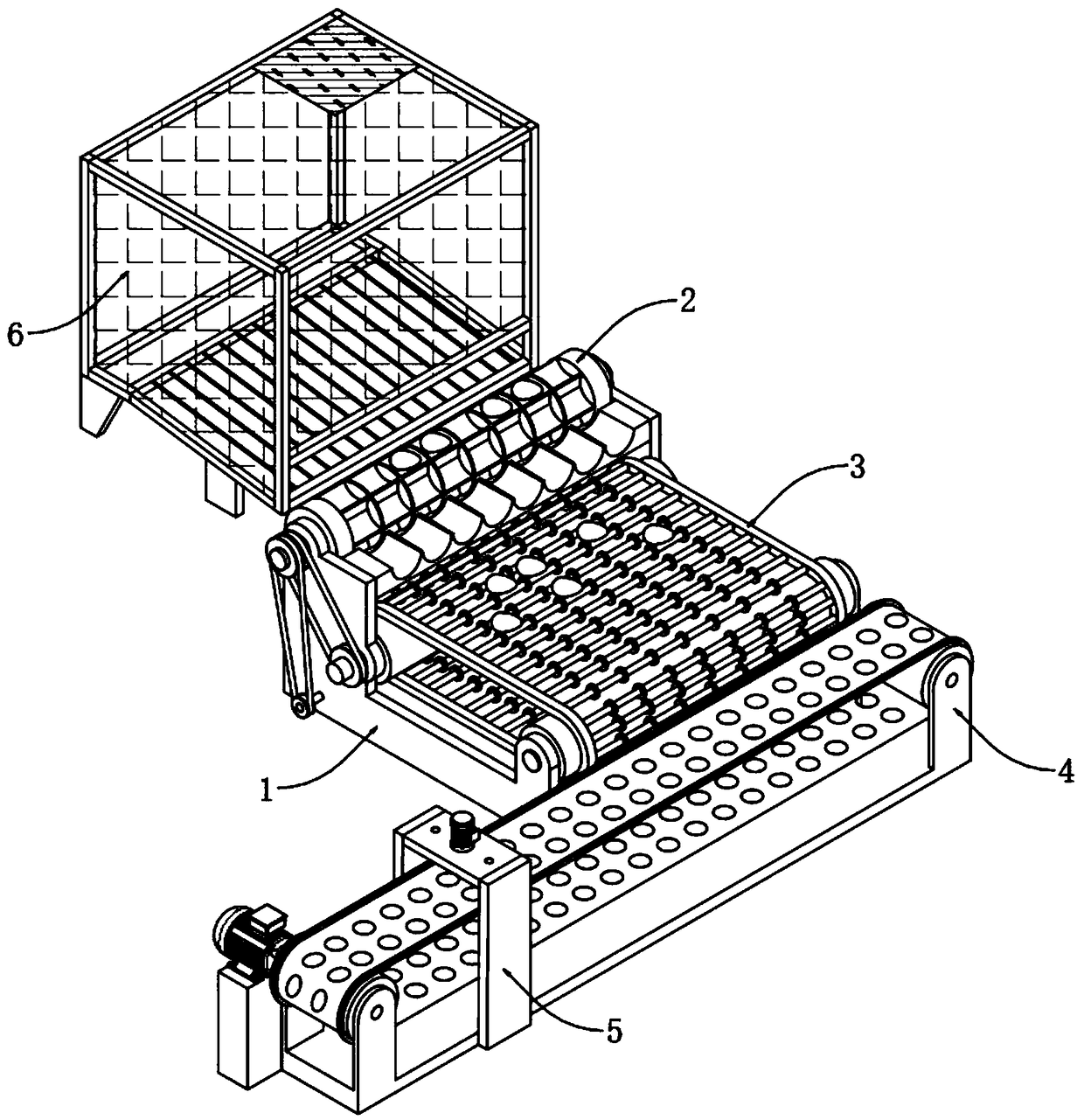

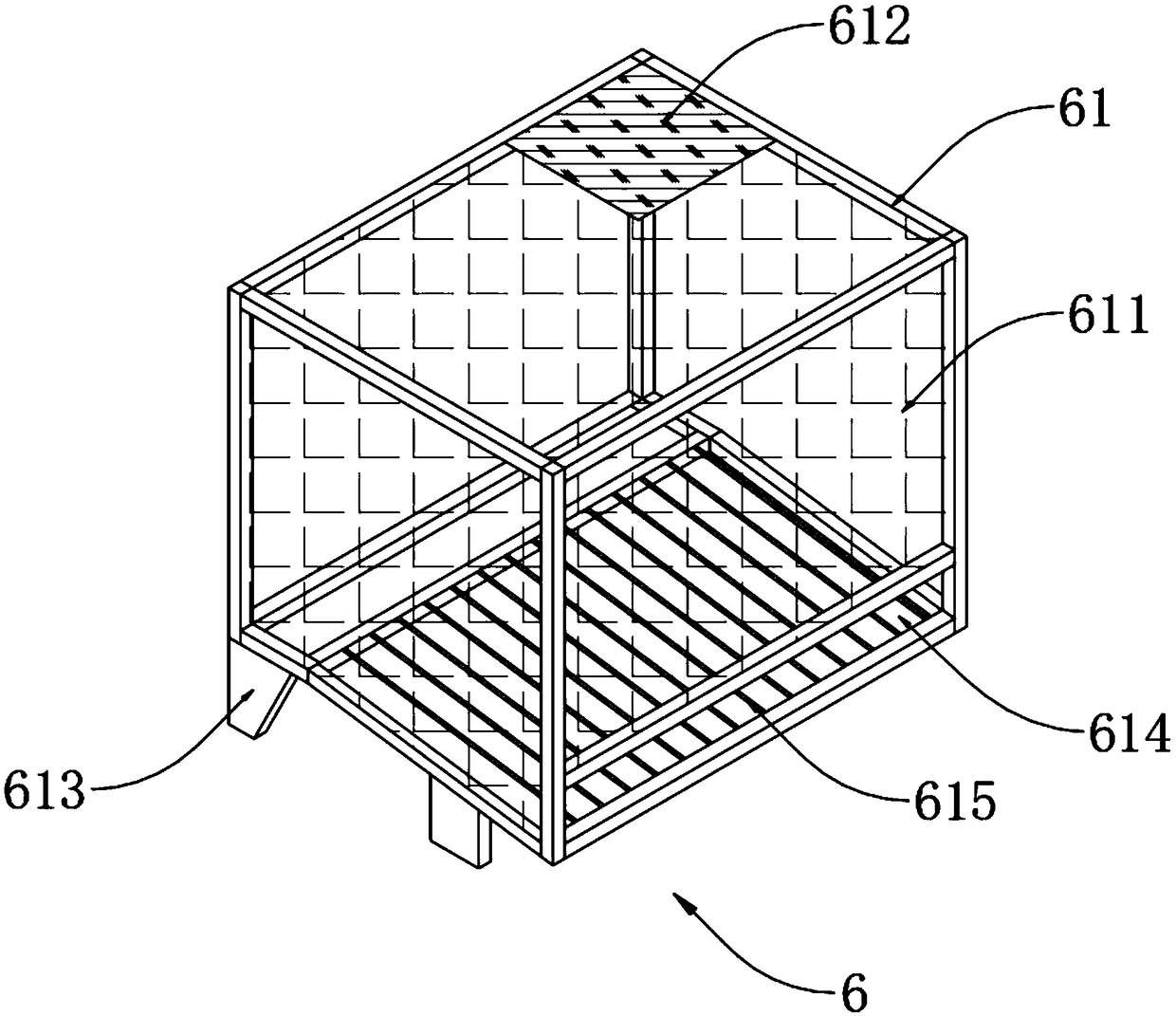

[0034] A kind of equipment for collecting eggs with low breakage rate for poultry farming, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the fixed device 1 is included, and the fixed device 1 is located on the front side of the breeding cage 6, and the egg shoveling device 2 is installed on one side of the top of the fixing device 1, and the breeding cage 6 includes a frame 61, and the outer surface of the frame 61 is tightly welded with a spacer 611, the top of the frame 61 is hinged with a top cover 612, the four corners of the bottom of the frame 61 are tightly welded with feet 613, the bottom position of the front end of the frame 61 is provided with an egg outlet 614, and the bottom of the frame 61 is installed There are a plurality of intercepting columns 615 arranged at equal intervals and inclined.

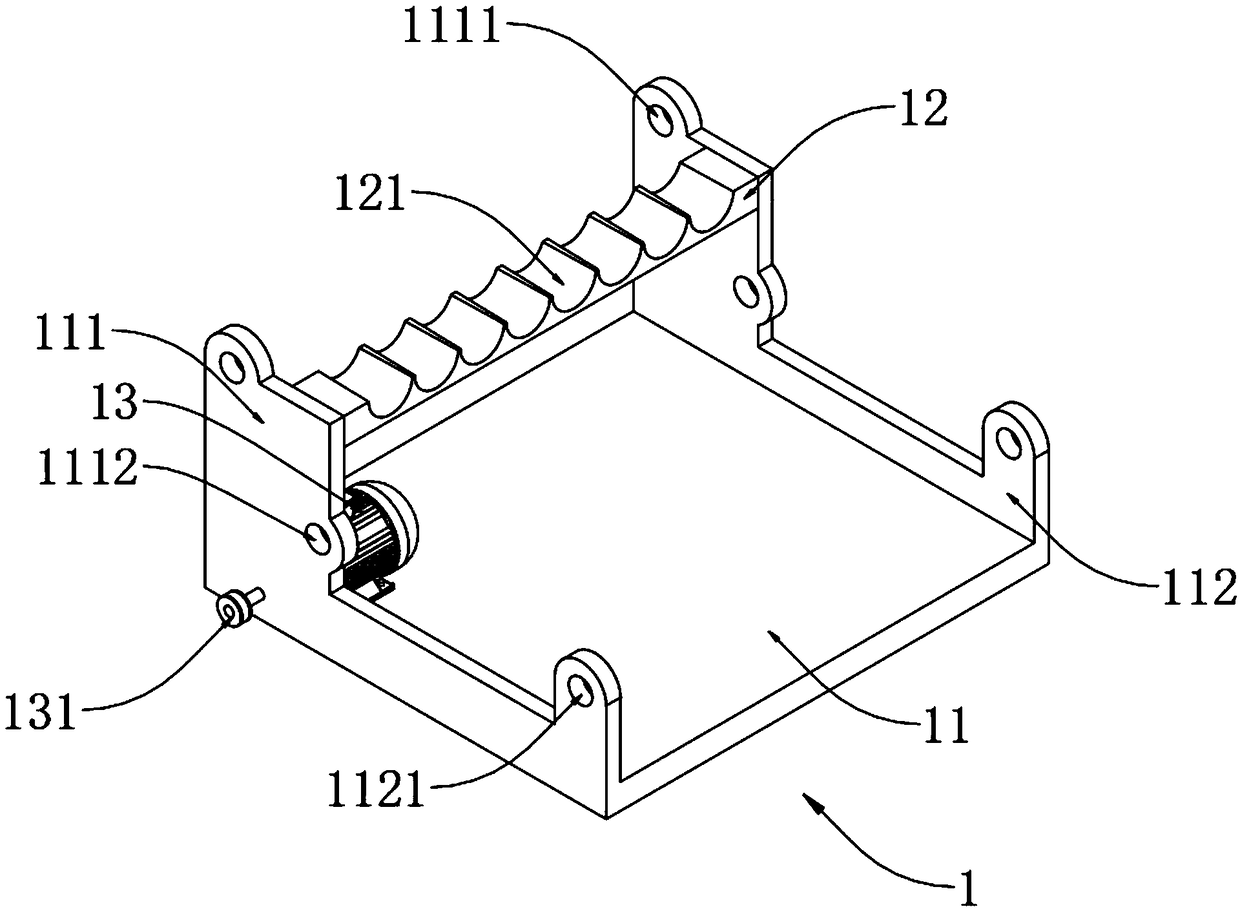

[0035] In this embodiment, the fixing device 1 includes a base 11, a guide plate 12 installed on the top of the base 11, and a first motor ...

Embodiment 2

[0041] In the specific operation, because when eggs are collected, the collision between eggs is likely to cause the problem of broken eggs, therefore, a dispersion device 3 is installed in front of the egg shoveling device 2, as a preferred embodiment ,Such as Figure 6 and Figure 7 As shown, the dispersing device 3 includes a driving roller 31 that is rotatably connected to the rear end seat 111, a driven roller 32 that is rotatably connected to the front end seat 112, and a roller that is sleeved on the outer edges of the driving roller 31 and the driven roller 32. A pair of conveyor bars 33.

[0042] In this embodiment, a driving roller 311 is tightly welded to the middle of the driving roller 31, and the driving roller 311 is installed in the second shaft hole 1112. The left end of the driving roller 311 is tightly welded with a third pulley 312. The three pulleys 312 and the second pulley 213 are connected by a belt, and the middle position of the driven roller 32 is ...

Embodiment 3

[0046] In the specific operation, because after the poultry lays eggs, the surface of the eggs is easily stained with feathers and other sundries, which requires staff to clean up outside, which is time-consuming and labor-intensive. Therefore, a conveying device 4 is provided at the front end of the dispersing device 3 , and a cleaning device 5 is provided on the outside of the conveying device 4, as a preferred embodiment, such as Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the conveying device 4 includes a base plate 41, a conveyor belt 42 installed above the base plate 41, and a second motor 43. A pair of left end seats 411 are tightly welded to the upper left end of the base plate 41. The cleaning device 5 includes a top plate 51 positioned above the conveyor belt 42. , a third motor 52 mounted on the top of the top plate 51 , a pair of vertical shafts 53 rotatably connected to the top plate 51 , and a cleaning brush 54 respectively sleeved on the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com