Plate roller engagement and disengagement mechanism of flexo-printing machine

A technology of flexographic printing machine and clutch pressure, which is applied in the direction of printing machine, rotary printing machine, rotary printing machine, etc. It can solve the problems of poor inking and ink receiving uniformity, poor printing quality and other problems of the plate roller, and achieve the joint pressure Stable state, improve printing quality, and eliminate the effect of unstable joint pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

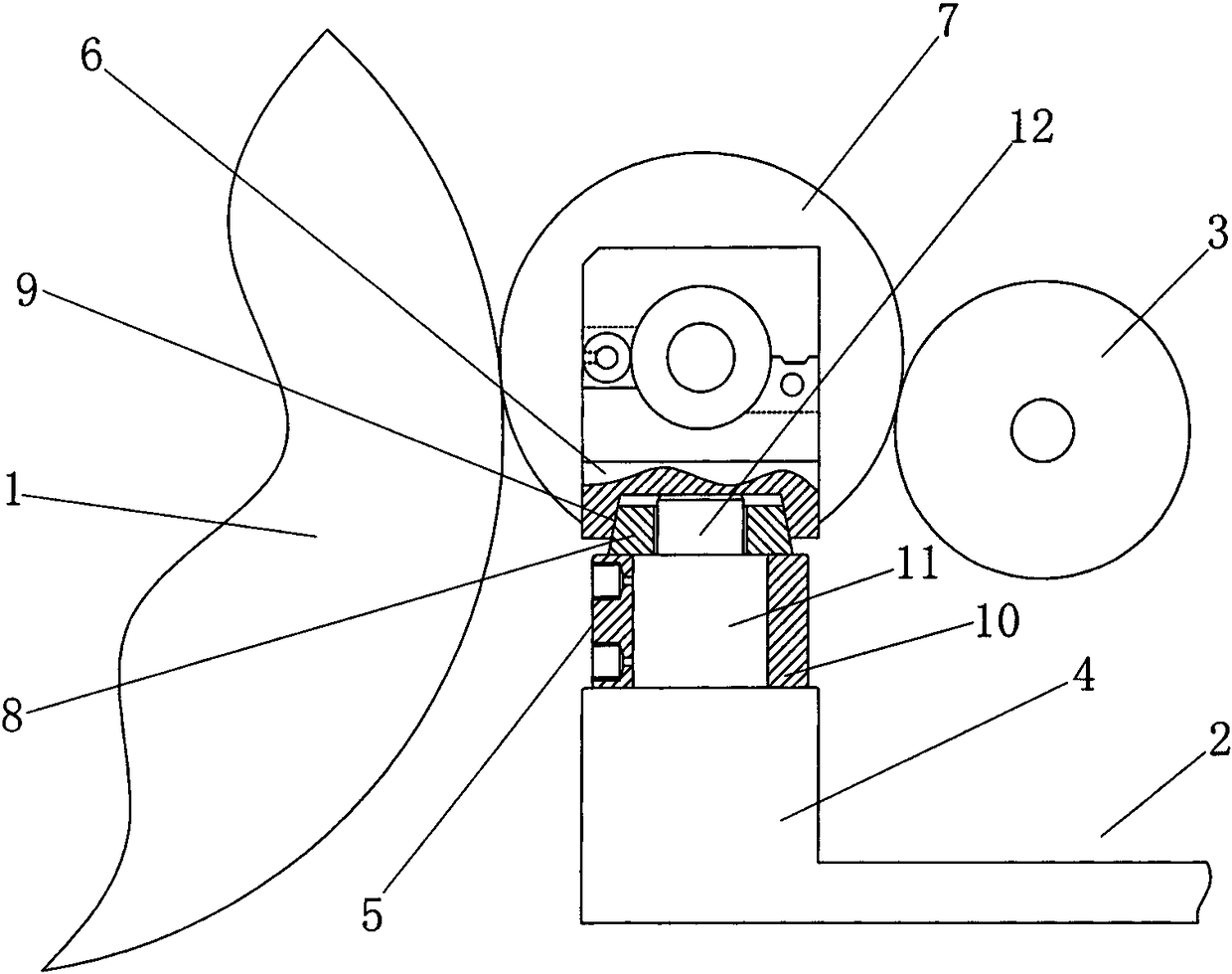

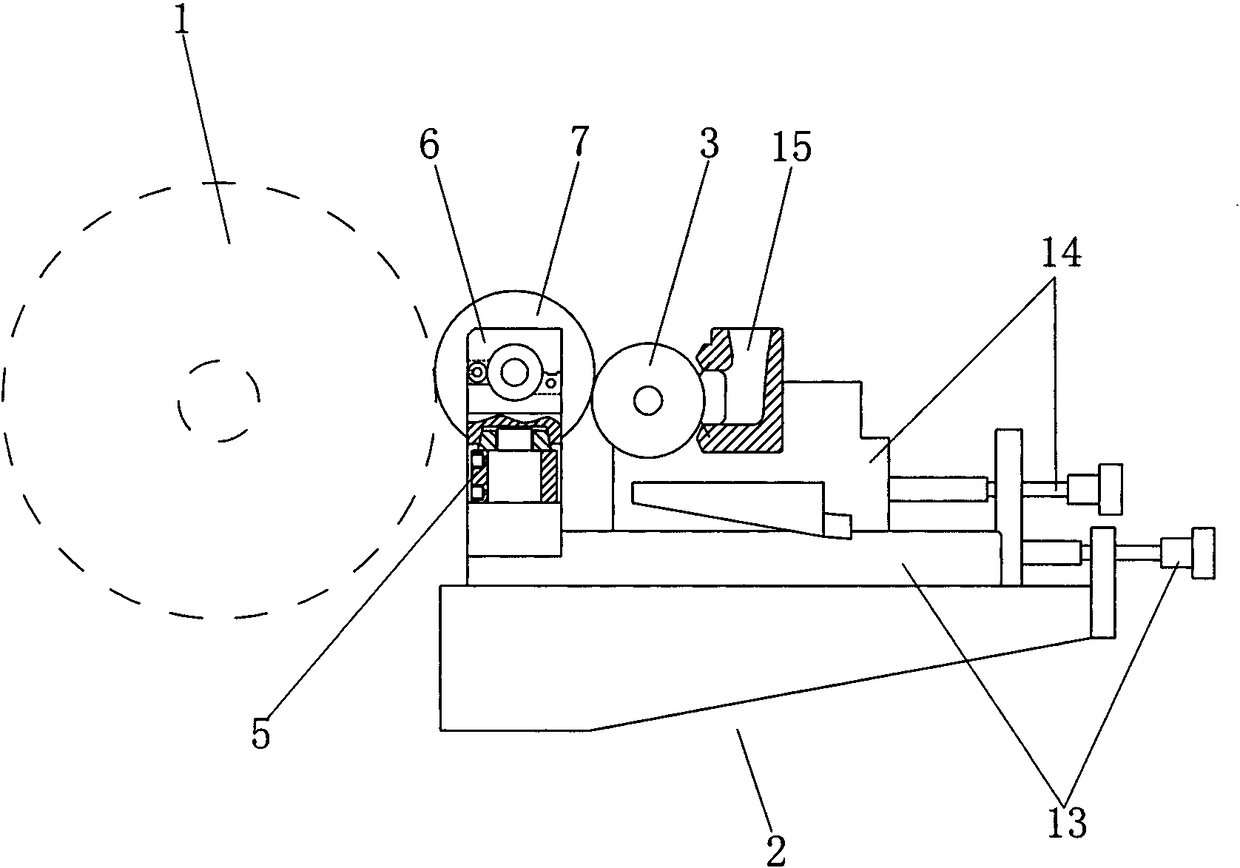

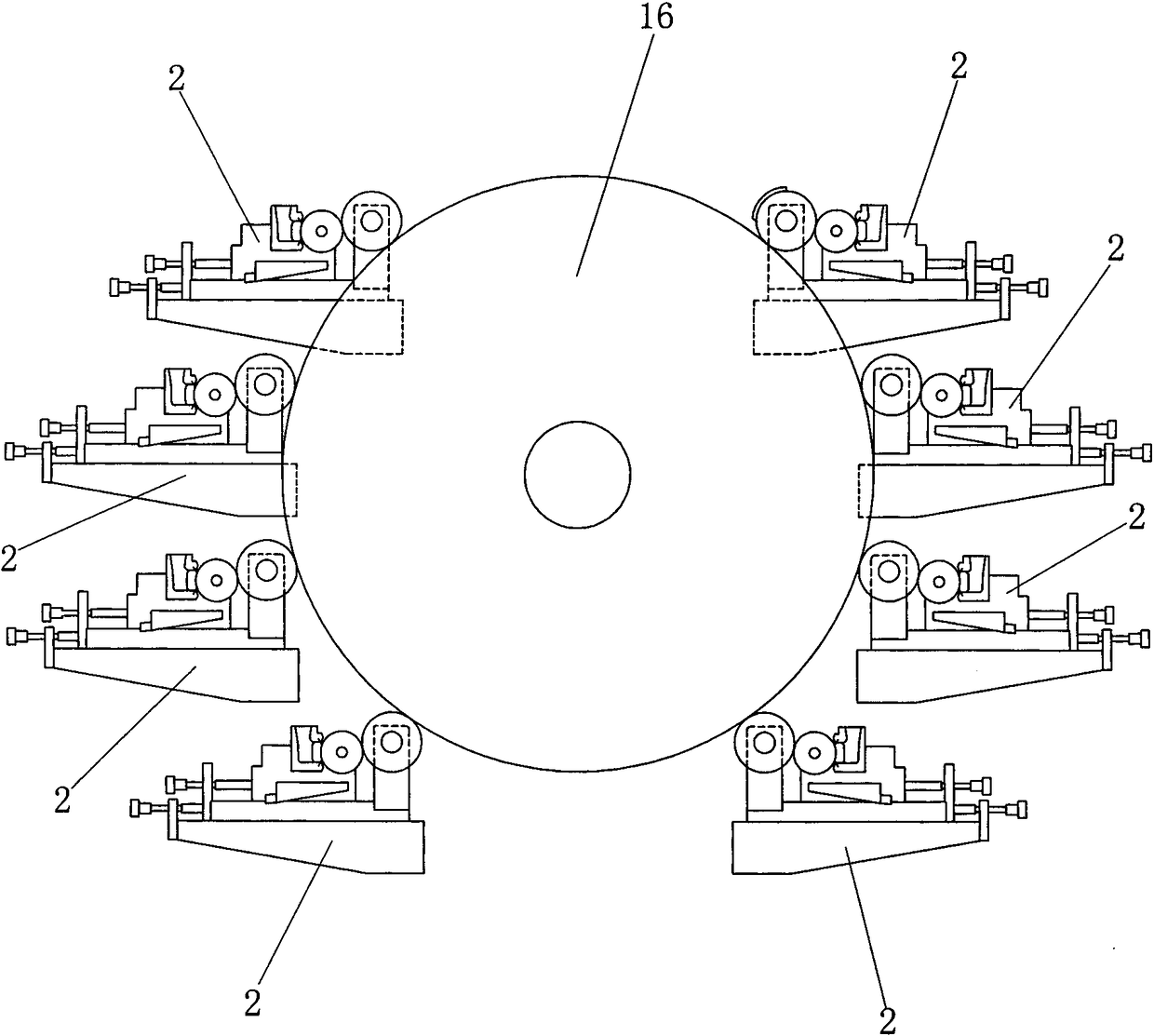

[0023] refer to figure 1 , the plate roller clutch press mechanism of this flexographic printing machine is composed of an impression cylinder 1 rotating and matching on the frame of the flexographic printing machine, an anilox roller 3 rotating and matching on the printing unit 2 of the flexographic printing machine, and fixed The lifter 5 on both sides of the unit frame 4 of the printing unit 2, the shoulder iron 6 that is slidably fitted on the unit frame 4 and matched with the driving end of the lifter 5, and the shoulder iron 6 that is rotationally fitted The version roller 7 on the top is composed of the version roller 7, the impression cylinder 1 and the anilox roller 3 are in the state of joint pressure or separation pressure, and the feature is that: the two sides of the unit frame 4 are equipped with the shoulder iron 6 The shoulder iron seat 8, the matching part 9 of the shoulder iron 6 and the shoulder iron seat 8 is a corresponding inclined surface, when the plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com