Synchronous driving type three-dimensional pattern hot-pressing type punching machine

A three-dimensional pattern and synchronous drive technology, which is applied in the field of synchronously driven three-dimensional pattern hot-pressing punching machines, can solve the problems of easy sticking materials, blurred three-dimensional patterns, and affecting product quality, so as to ensure quality and solve easy sticking materials , three-dimensional pattern clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

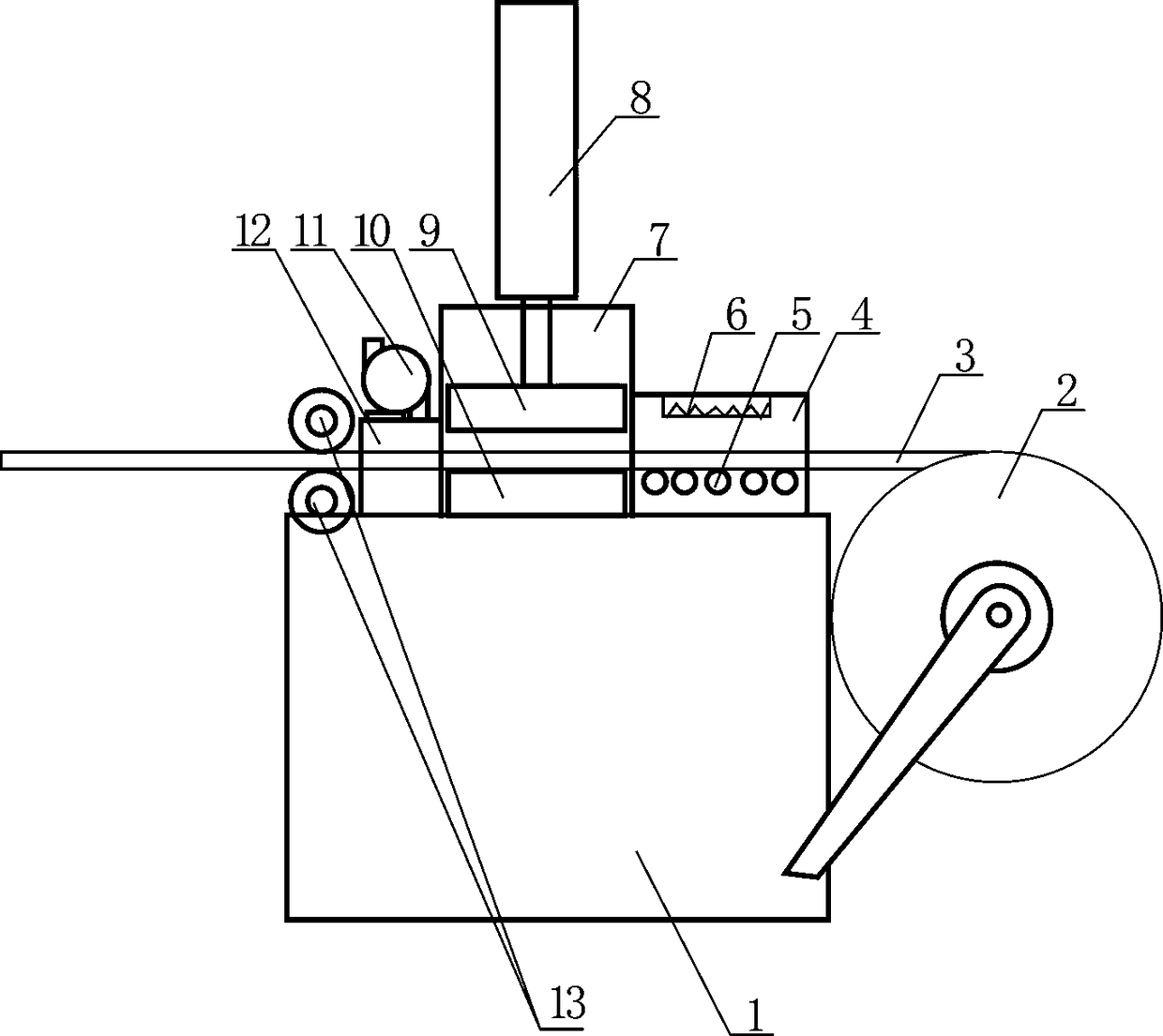

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0018] Such as figure 1 As shown, the synchronously driven three-dimensional pattern hot-pressing punching machine includes an organic base 1, a plastic sheet reel 2, a preheating box 4, an electric heating wire 6, a hot pressing box 7, a hydraulic cylinder 8, and a three-dimensional pattern stamping male die 9. The three-dimensional pattern stamping die 10, the cooling box 12, the blower fan 11 and the driving pressure roller group 13, the driving pressure roller group 13 is driven by the same motor, and the plastic sheet reel 2 is arranged on one side of the machine base 1, and the driving pressure roller group 13 is driven by the same motor. The wheel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com