A control method for an internal unit valve of a multi-connected air-conditioning system

A technology of multi-connected air conditioners and control methods, applied in heating and ventilation safety systems, heating and ventilation control systems, mechanical equipment, etc., can solve problems such as dirty blockage of external units, frequent protection and shutdown of internal valves, and insufficient refrigerant installation environment. , to achieve the effect of reducing the probability of exhaust protection shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

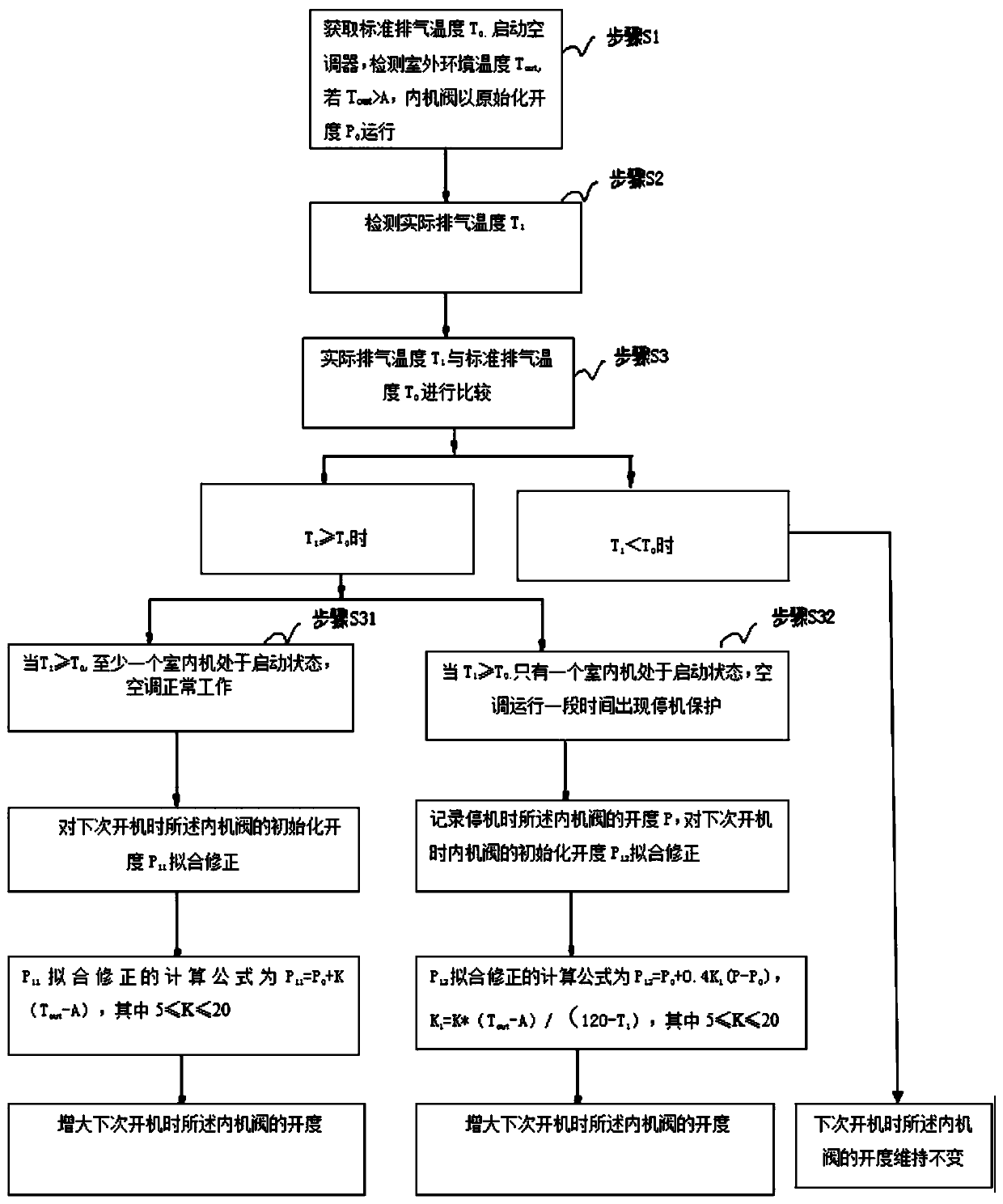

[0029] Such as figure 1 , the present embodiment provides a method for controlling an internal valve of a multi-connected air-conditioning system, which includes the following steps:

[0030] Step S1, obtain the standard exhaust temperature T 0 , start the air conditioner, and detect the outdoor ambient temperature T out , if T out >A, the internal machine valve is opened with the original opening degree P 0 run;

[0031] Step S2, when the operation in step S1 ends, detect the actual exhaust gas temperature T 1 ;

[0032] Step S3, the actual exhaust temperature T of step S2 1 With step S1 standard exhaust temperature T 0 are compared when T 1 ≥T 0 , the initialization opening degree P of the internal machine valve at the next start-up 1 Fitting correction, increasing the opening degree of the internal machine valve increases the opening degree of the internal machine valve when starting up next time; when T 1 0 , the opening of the internal unit valve will remain un...

Embodiment 2

[0038] The present embodiment is the application instance of embodiment 1, specifically as follows:

[0039] In this example, it is assumed that the ambient temperature T out >48°C, this embodiment is a method for controlling the internal valve of a multi-connected air-conditioning system, which includes the following steps:

[0040] Step S1, obtain the standard exhaust temperature T 0 is 105°C, start two indoor air conditioners, and detect the outdoor ambient temperature T out at 55°C, the valve of the internal machine takes the original opening degree P 0 Run for 2 minutes at 160, that is, the internal machine valve is opened at the original opening degree P 0 After running for 2 minutes, the internal machine valve starts to automatically adjust;

[0041] Step S2, when the operation in step S1 ends, detect the actual exhaust gas temperature T 1 is 120°C;

[0042] Step S3, the actual exhaust temperature T of step S2 1 With step S1 standard exhaust temperature T 0 are ...

Embodiment 3

[0044] The present embodiment is the application instance of embodiment 1, specifically as follows:

[0045] In this example, it is assumed that the ambient temperature T out >45°C, this embodiment is a method for controlling the internal valve of a multi-connected air-conditioning system, which includes the following steps:

[0046] Step S1, obtain the standard exhaust temperature T 0 is 100°C, start two indoor air conditioners, and detect the outdoor ambient temperature T at this time out at 50°C, the valve of the internal machine takes the original opening degree P 0 Run for 1min at 190, that is, the internal machine valve is opened at the original opening degree P 0 After running for 1 minute, the internal machine valve starts to automatically adjust;

[0047] Step S2, when the operation in step S1 ends, detect the actual exhaust gas temperature T 1 90°C;

[0048] Step S3, the actual exhaust temperature T of step S2 1 With step S1 standard exhaust temperature T 0 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com