3D glass and film fitting fixture component

A technology for laminating fixtures and glass, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems that the fixtures cannot be used universally, the glass cannot be clamped very firmly, and the dimensional accuracy cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

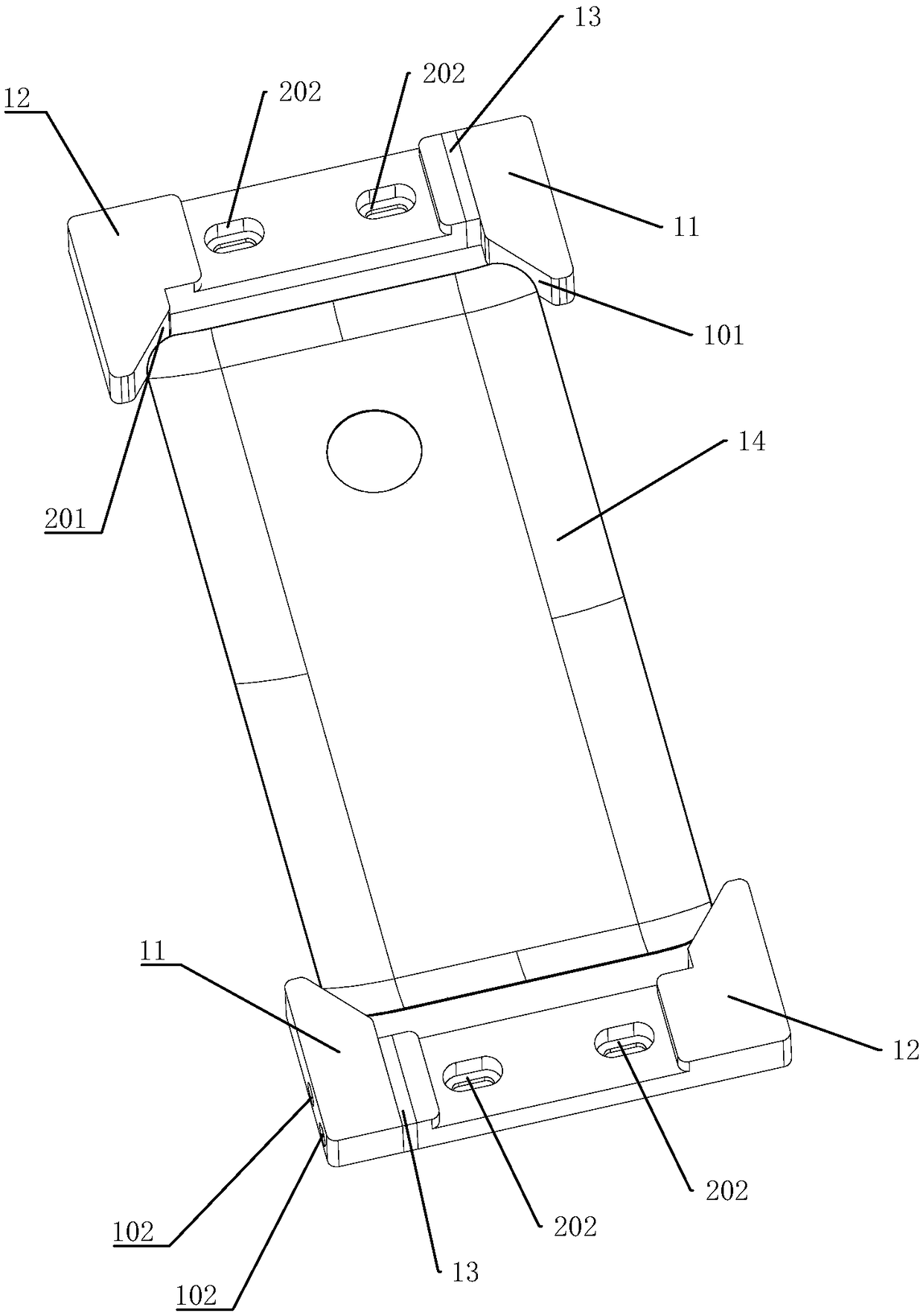

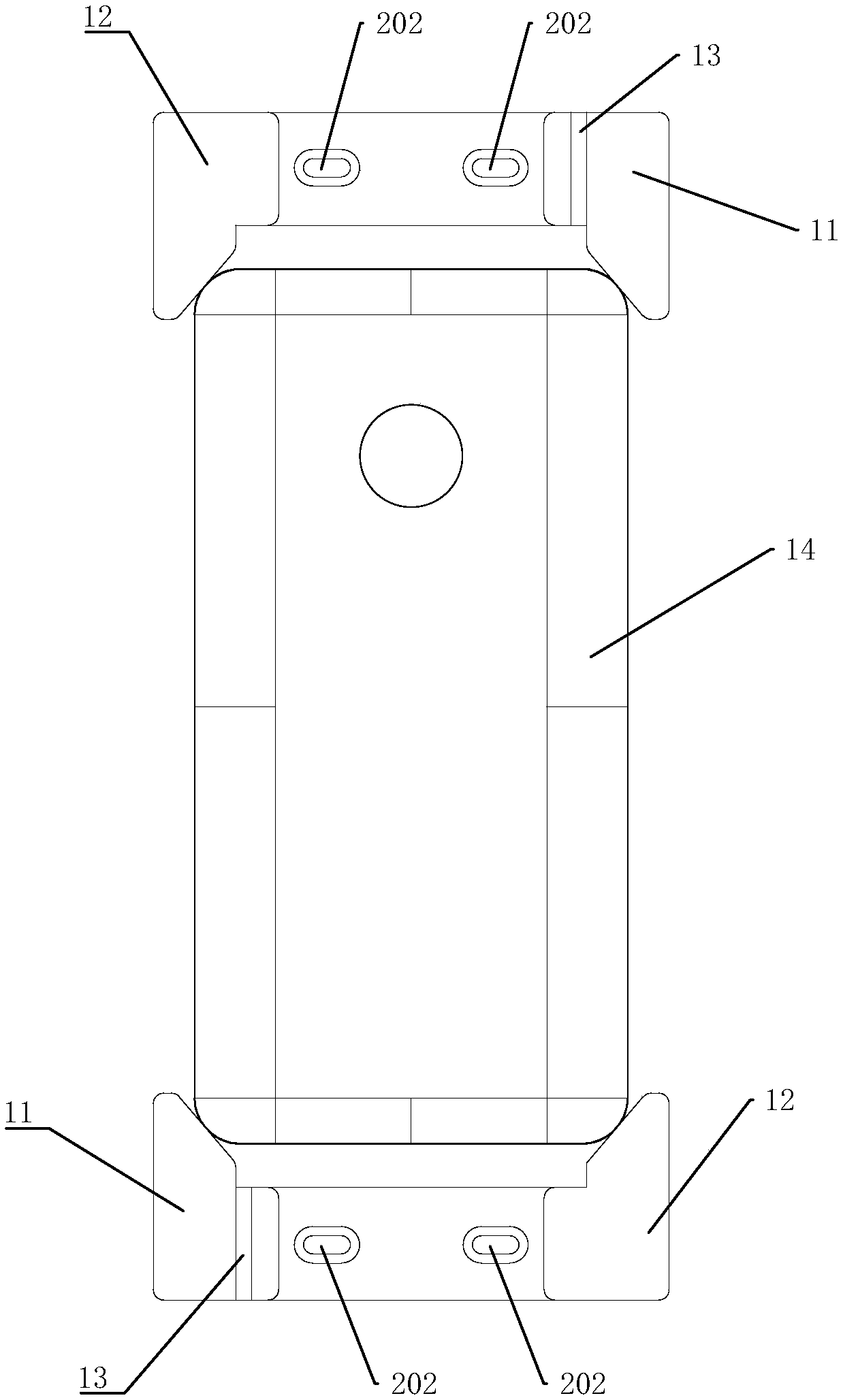

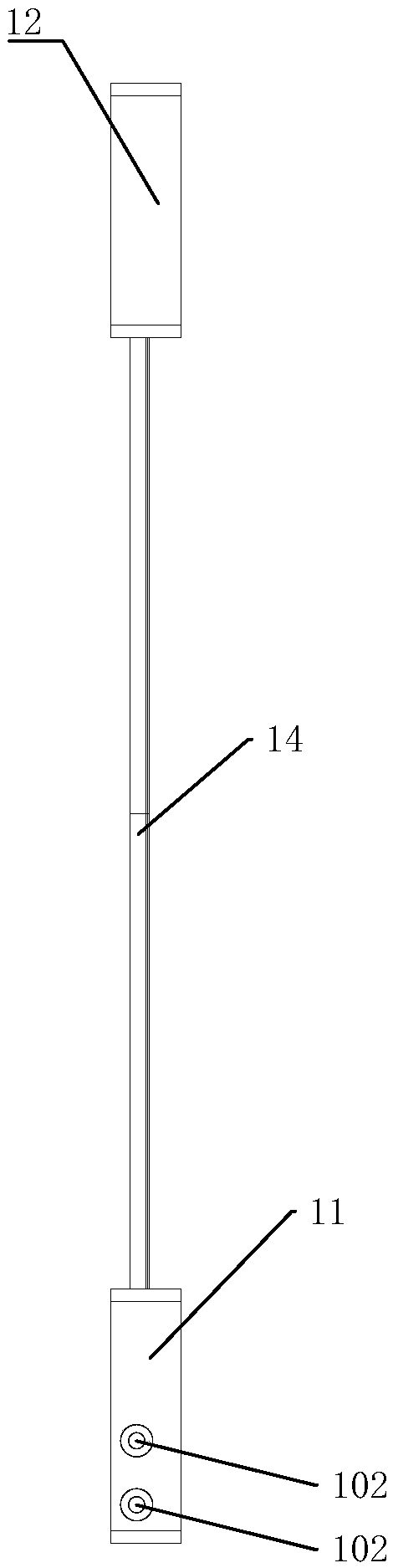

[0022] Such as Figure 1-Figure 5 Shown: a 3D glass film bonding fixture assembly of the present invention, used to clamp 3D glass 14, including a first clamping part 11, a second clamping part 12, and a spacer 13; the first clamping part 11 is provided with a clamping plane 101, the clamping plane 101 is in contact with a point on the corner of the 3D glass 14, the first clamping plane 101 is perpendicular to the upper and lower surfaces of the first clamping part 11, and the second clamping The part 12 is provided with a clamping plane 201 and a U-shaped screw hole 202, the clamping plane 201 is in contact with a point on the corner of the 3D glass 14, and the clamping plane 201 is perpendicular to the upper and lower surfaces of the first clamping part 11, The way of point contact enables the clamping part 11 and the clamping part 12 to better clamp the 3D glass 14 .

[0023] In this embodiment, the pad 13 is placed between the first clamping portion 11 and the second clam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap