Stackable system container

A container and coupling connection technology, applied in the field of system containers, can solve the problems of less modular application and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

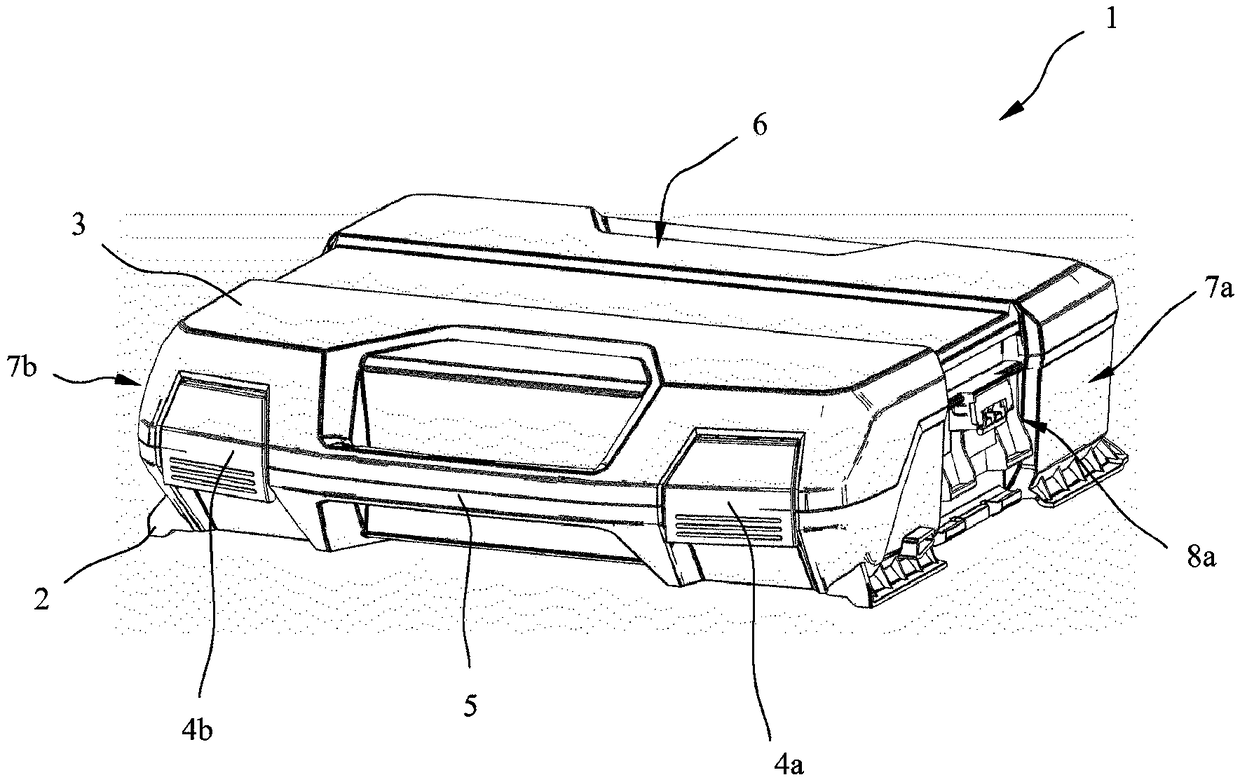

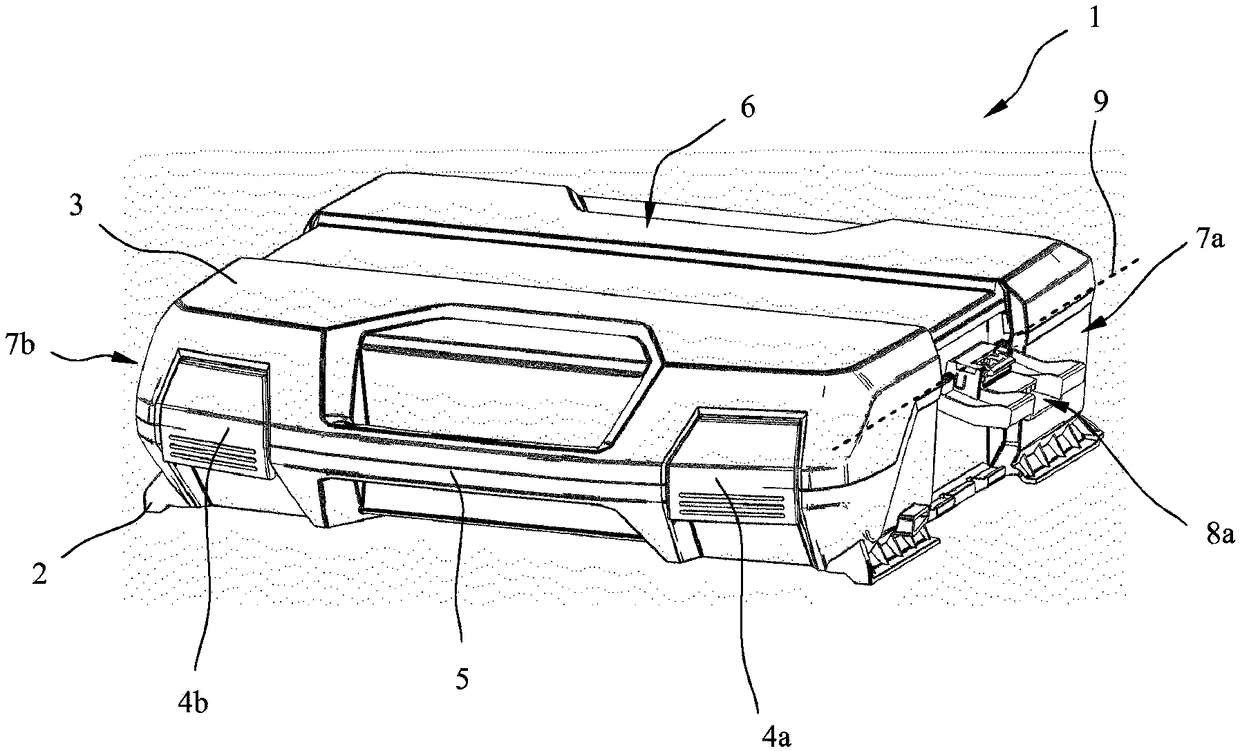

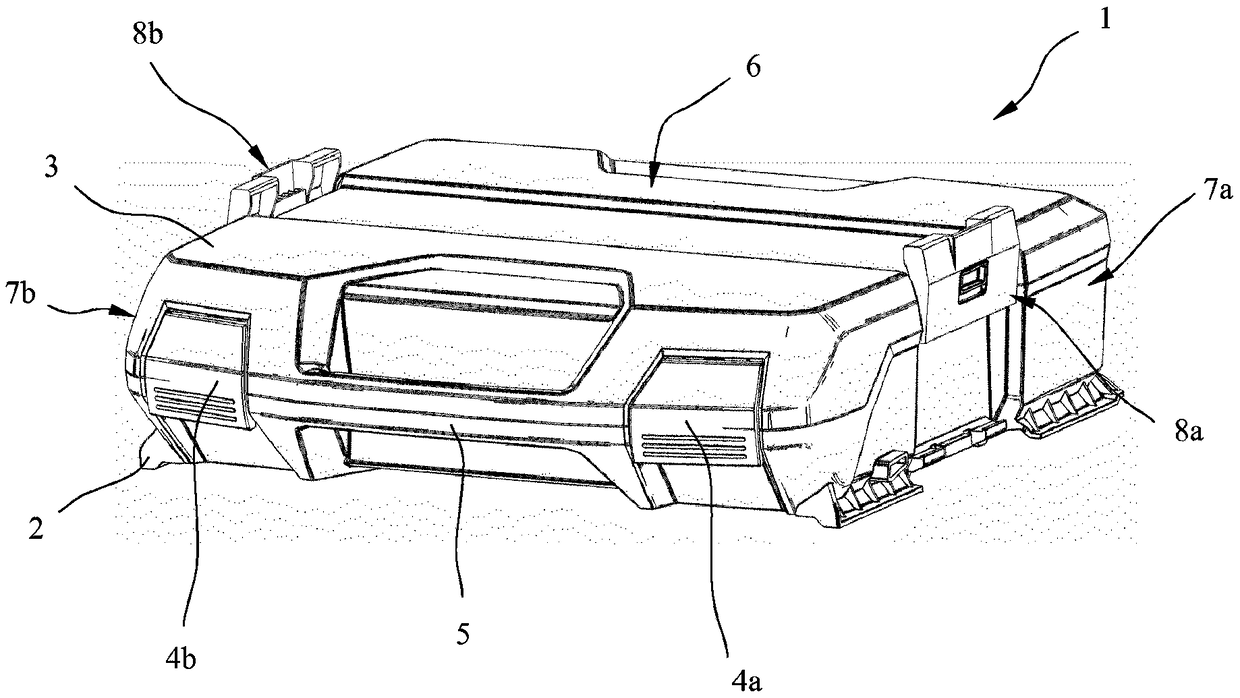

[0031] figure 1 A perspective view of a stackable system container 1 is shown. The system container 1 includes a lower bottom part 2 and a cover part 3 pivotally mounted above the bottom part 2 . However, the cover part 3 can also be constructed separately from the base part 2 . The bottom part 2 has a storage space, not shown, which is open upwards and which is bounded upwards by the cover part 3 . The cover part 3 is pivotally connected with the bottom part 2 by a pivot joint provided at the rear edge of the cover part 3 . In order to releasably mount the lid part 3 on the bottom part 2 and thus securely close the closed storage space, two closure devices 4a, 4b are provided on the front side of the system container 1, which are hingedly mounted on the lid part 3 In the closed position shown, the cover part 3 cooperates in a locking manner with the base part 2 .

[0032] The system container 1 can be used, for example, to transport and store a craftsman's tools and work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com