Sorting robot

A technology of a robot and a robot base, applied in the field of robots, can solve the problems of large load at the rotating shaft of the single-axis overturned pallet structure, unloading of goods, and unfavorable sorting of goods, etc., to achieve the effect of reducing the risk of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

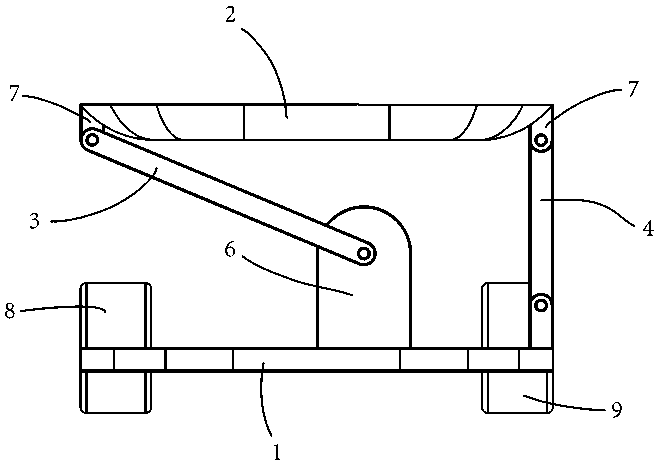

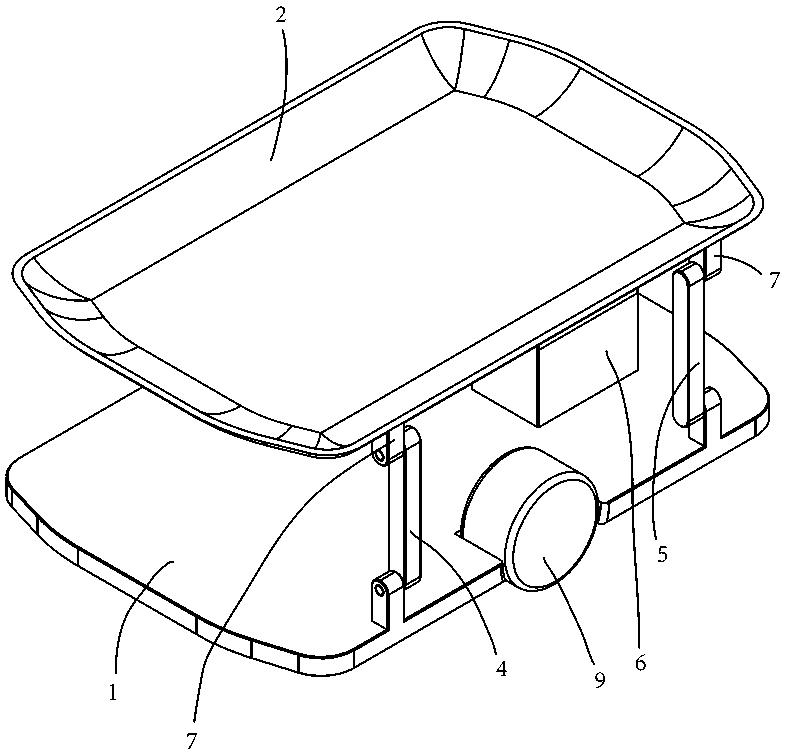

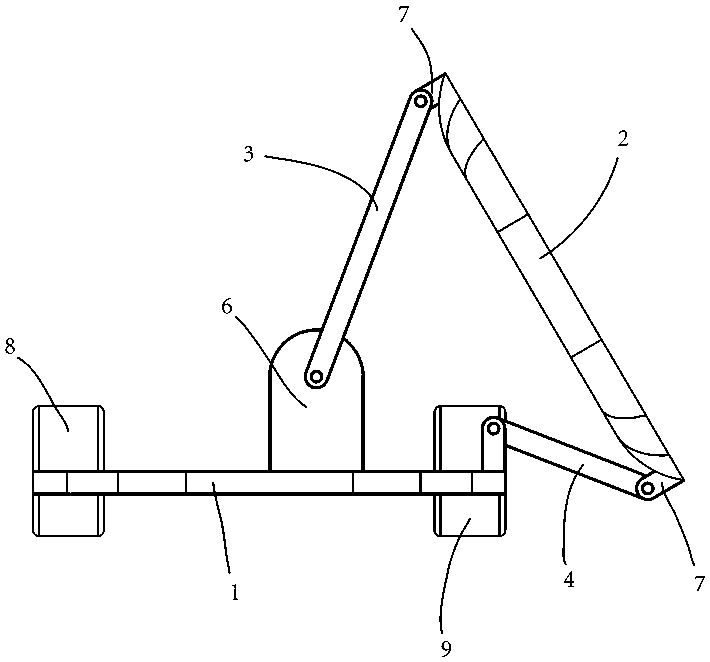

[0022] Example 1 as Figure 1~4 As shown, a sorting robot includes a robot base and a tray, and the sorting robot base includes up to two driving wheels, a robot moving power device, a path control device, a pallet unloading power device and a power supply module, and the sorting robot also It includes a first connecting rod and a second connecting rod. One end of the first connecting rod is fixedly connected to the output end of the pallet unloading power device. The other end of the first connecting rod is connected to the connecting rod pillar on the pallet through a bearing and the bearing axis is connected to the pallet unloading power device. The axis of the output shaft of the power unit is parallel and not coaxial. One end of the second connecting rod is connected to the connecting rod pillar on the pallet through a bearing, and the other end is connected to the robot base through a bearing, and the bearing axes at both ends of the second connecting rod are connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com