Combined nut cracking device

It is a compound type and nuclear device technology, which is applied in the field of daily tools, and can solve the problems of cumbersome manual nuclear opening, low efficiency, hard walnut shells, etc., and achieve the effect of simple overall structure, good effect of nuclear opening, and high efficiency of nuclear opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

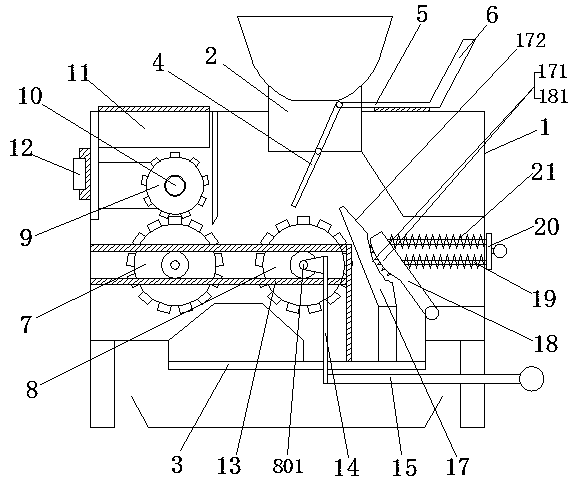

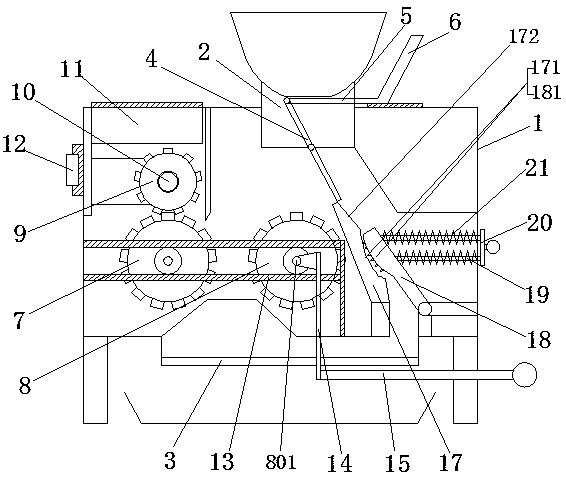

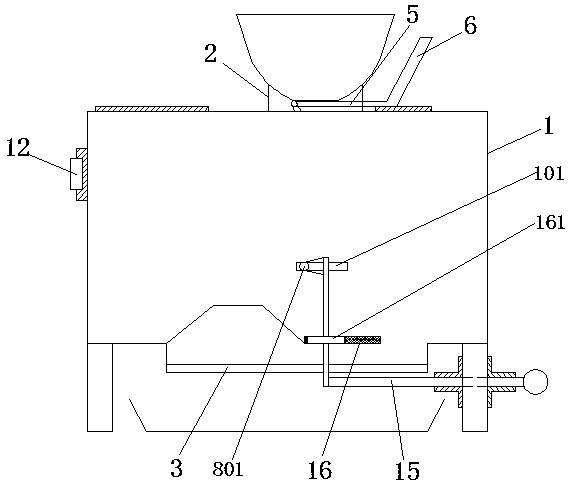

[0026] As shown in the figure, the present invention is a composite walnut pitting device, comprising a casing 1, a feed pipe 2 arranged at the top of the casing 1, and a walnut outlet 3 arranged at the bottom of the casing 1, and the casing 1 is provided with an electric A nuclear mechanism and a manual mechanism, the feed pipe 2 is provided with a switching mechanism for introducing walnuts into an electric mechanism or a manual mechanism.

[0027] In this embodiment, the switching mechanism includes a deflector 4 and two push rods 5 horizontally sliding through the top nozzle of the feed pipe 2. The center of the deflector 4 is connected to the feeding At the bottom outlet of the tube 2, the two ends of the two push rods 5 located in the feed tube 2 are respectively hinged at the two ends of the top of the deflector 4, and the two push rods 5 are located at the two ends outside the feed tube 2. A push plate 6 is connected between the parts, and the push plate 6 drives the d...

Embodiment 2

[0042] The main body of this embodiment is the same as that of Embodiment 1. The only difference is that, on the basis of Embodiment 1, this embodiment evenly arranges a plurality of pointed protrusions on the surface of the arc-shaped protrusion 181 to ensure the impact force of the impact plate 18. In the case of walnuts, the crushing effect of walnuts has been improved. In addition, a discharge bin with a funnel-shaped structure is arranged on the top of the feed pipe 2 .

Embodiment 3

[0044] The main body of this embodiment is the same as that of Embodiment 1. The only difference is that this embodiment is based on Embodiment 1. The top of the fixed platen 17 facing the side of the impact plate 18 is provided with a The inclined guide surface 172 for receiving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com