3D printing pen capable of swinging and extending to supplement materials

A 3D printing pen and feeding technology, applied in the field of 3D printing, can solve the problem of small use range, and achieve the effect of convenient feeding of raw materials and wide use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

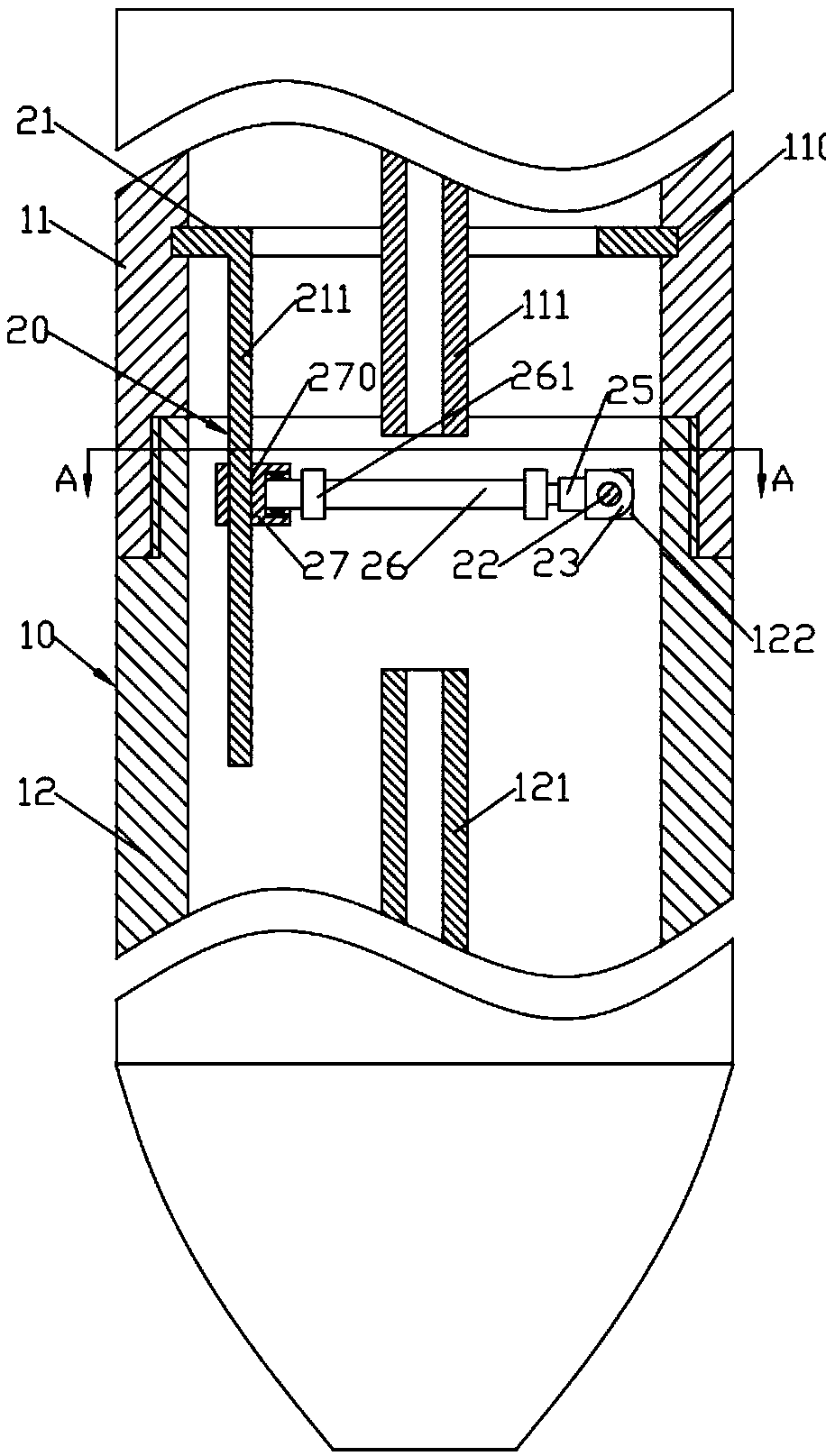

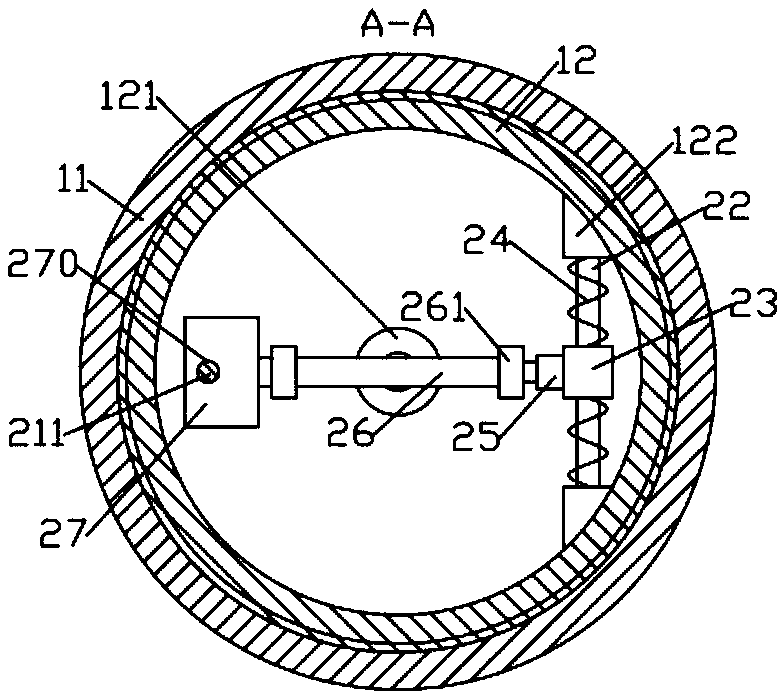

[0013] Such as figure 1 with figure 2 As shown, a 3D printing pen that oscillates and stretches out the filling material includes a pen holder body 10 and a feeding device 20; a hollow space with a cylindrical groove is formed inside the pen holder body 10; the pen holder body 10 includes an upper pen holder 11 and a lower pen holder 12; The penholder 11 is screwed to the upper end of the lower penholder 12; the inner cylindrical surface of the upper penholder 11 is pivotally connected with an annular upper support ring 21; the lower end surface of the upper support ring 21 is formed with a cylindrical limit rod 211; The upper right part of the inner cylindrical surface of the pen holder 12 is fixed with a cylindrical swing center column 22 in the front and rear direction; the center of the swing center column 22 is pivotally connected with a swing support block 23; 24; one end away from a pair of torsion springs 24 is fixed on the inner cylindrical surface of the lower pen ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap