Spring parallel connection variable-stiffness friction-adjustable buffer

A friction and adjustable technology, applied in the direction of spring/shock absorber, shock absorber, shock absorber, etc., can solve the problem of large axial size and inappropriate installation space, and achieve small axial size and simple installation. , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

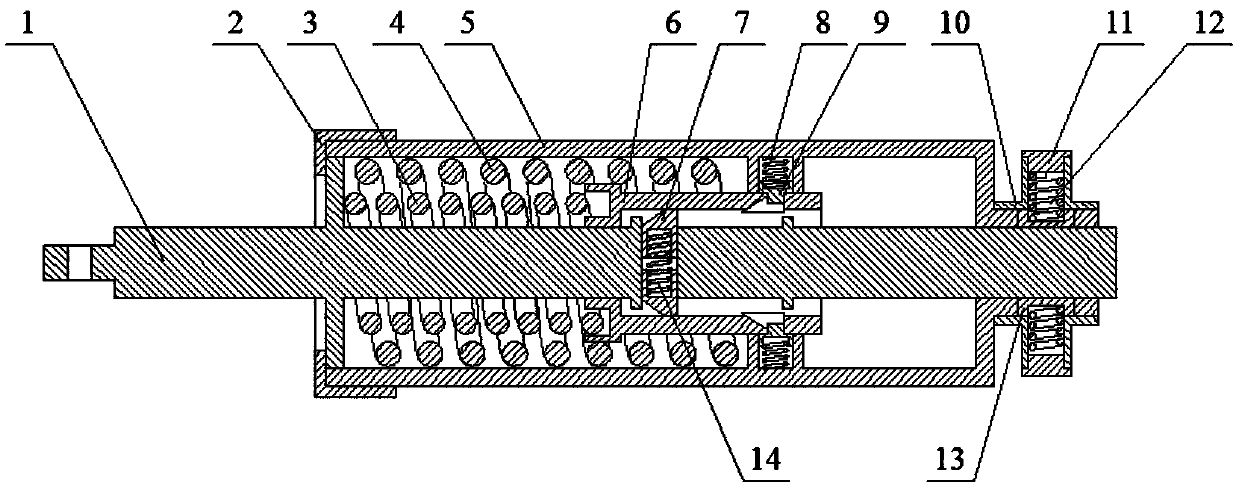

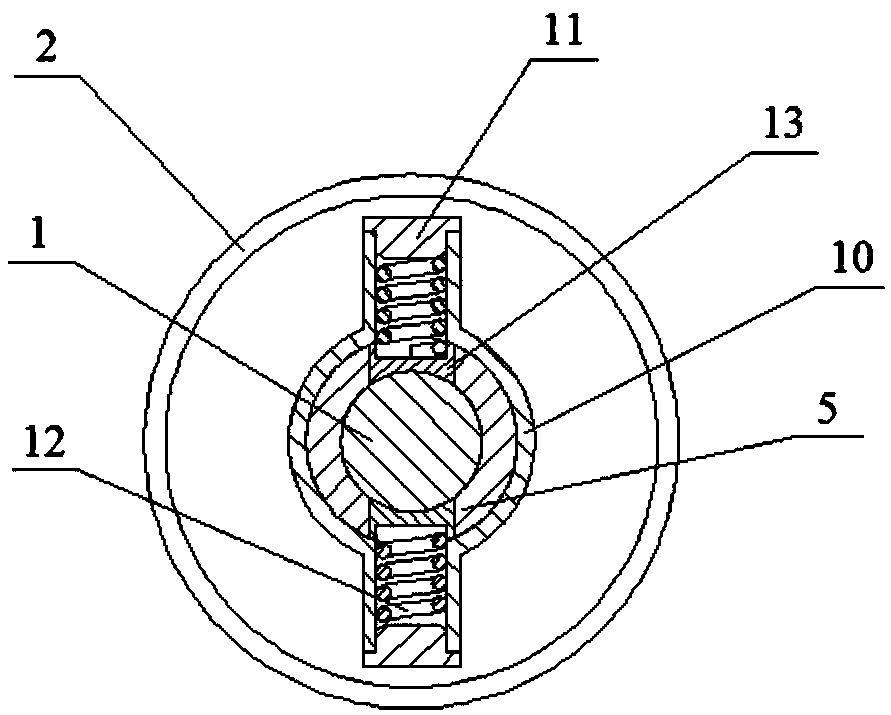

[0060]The spring parallel variable stiffness friction adjustable buffer shown in this embodiment includes a pull rod 1, an end cover 2, an inner ring spring 3, an outer ring spring 4, an outer sleeve 5, an inner sleeve 6, a pull rod buckle 7, and an outer sleeve. Sleeve buckle spring 8, outer sleeve buckle 9, outer hoop 10, plug 11, adjustment spring 12, friction block 13, pull rod buckle spring 14. The pull rod 1 has a through pull rod round hole 101 and a pull rod square hole 108 , the axis of the pull rod round hole 101 is vertically upward with the axis of the pull rod square hole 108 , and is perpendicular to the axis of the pull rod 1 . The pull rod 1 has a pull rod cover 1014 , a first pull rod shoulder 106 and a second pull rod shoulder 109 in sequence. The rod cover 1014 has a first end surface 102 of the rod cover, a cylindrical surface 103 of the rod cover, and a second end surface 104 of the rod cover. The pull rod 1 has a pull rod front cylinder 105 and a pull ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap