A kind of temperature-resistant composite clean fracturing fluid and its preparation method

一种清洁压裂液、耐温型的技术,应用在化学仪器和方法、钻孔的组合物等方向,能够解决无法降解、适用范围低、无法满足现场应用推广等问题,达到增强胶束网状结构强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the temperature-resistant composite clean fracturing fluid comprises the following steps:

[0031] (1) Disperse ordinary hydrophilic nano-silica in an organic solvent with an ultrasonic cleaner, then add acid anhydride organic matter, and stir magnetically at room temperature for 15 hours at a speed of 600-700 rpm to obtain acid anhydride-modified nano-silica. particle reaction solution.

[0032] (2) Put the anhydride-modified nanoparticle reaction solution obtained in step (1) into a high-speed centrifuge for high-speed centrifugation at a speed of 9000 rpm and a centrifugation time of 30 minutes. Collect the centrifuged product and wash it with ethanol for 3 times to remove untreated particles. After the fully reacted acid anhydride organic matter is washed with ethanol, it is vacuum-dried to remove the remaining organic solvent and ethanol, and the dried solid is ground to obtain the acid anhydride-modified nano-silica particles.

[0033] (...

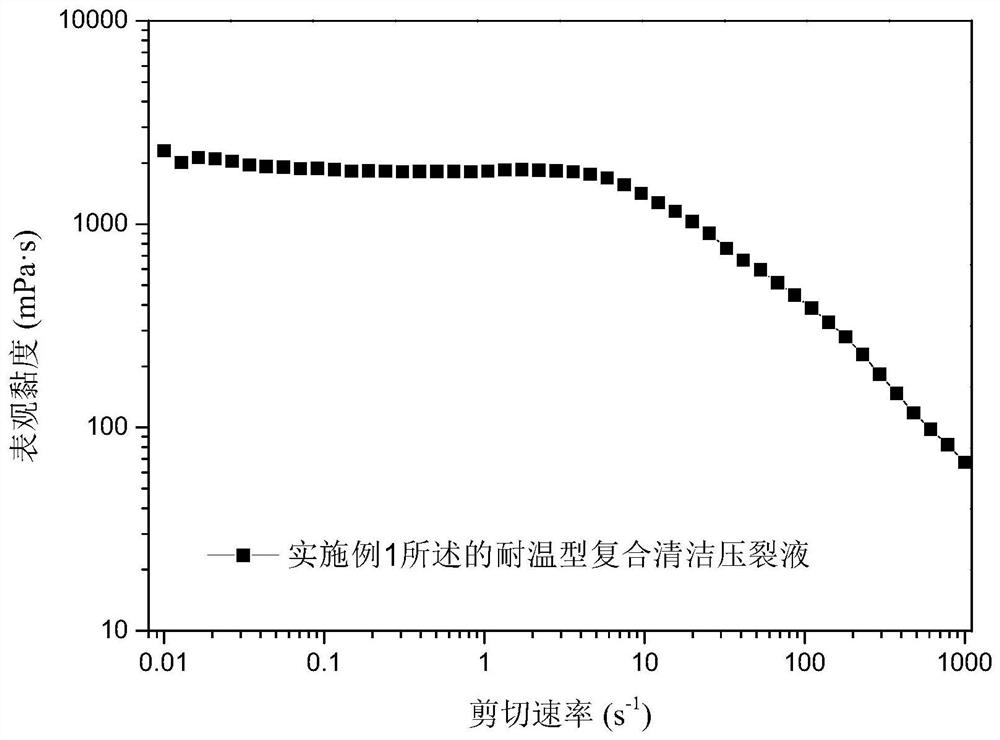

Embodiment 1

[0037] A temperature-resistant composite clean fracturing fluid, its components and mass percentages are as follows:

[0038]Behenamidopropyldimethylamine 1%; Sodium Salicylate 1%; Modified Nanoparticles 1% and the balance water.

[0039] The preparation method of the temperature-resistant composite clean fracturing fluid comprises the following steps:

[0040] (1) 2g particle size is 20nm, specific surface area 240m 2 / g of ordinary hydrophilic nano-silica is dispersed in 200ml of N,N-dimethylamide using an ultrasonic cleaner, then 2g of maleic anhydride is added, and magnetically stirred at room temperature for 15 hours at a speed of 600 rpm, that is The reaction solution of maleic anhydride modified nanoparticles was obtained.

[0041] (2) Put the maleic anhydride modified nanoparticle reaction liquid obtained in step (1) into a high-speed centrifuge and carry out high-speed centrifugation, the rotating speed is 9000 rpm, and the centrifugation time is 30 minutes; the cen...

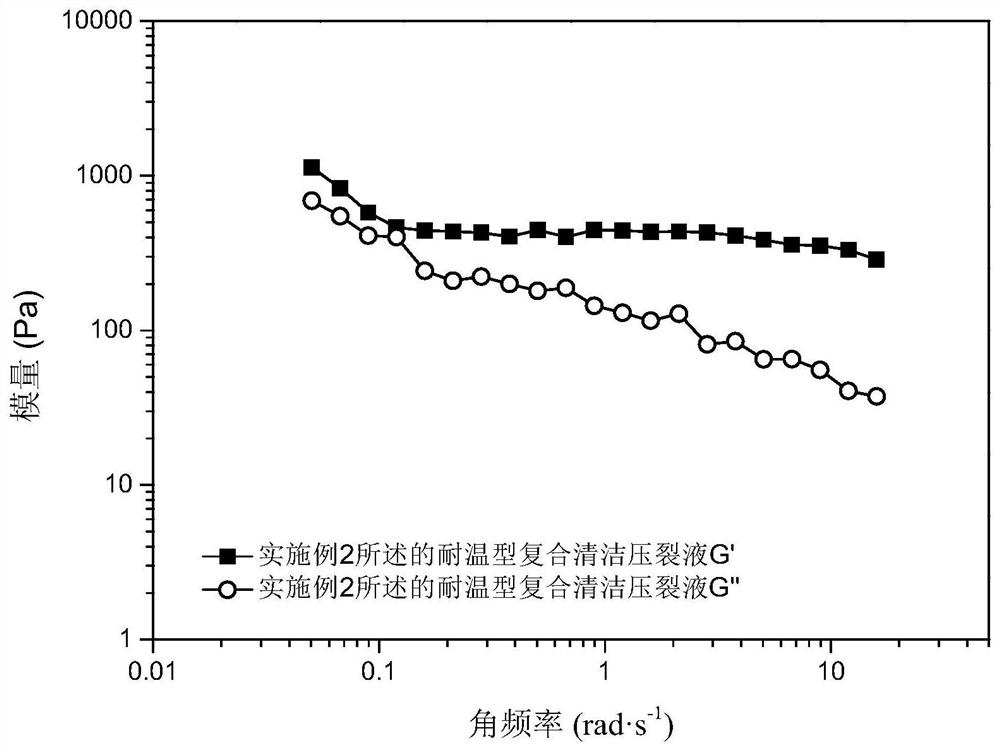

Embodiment 2

[0047] A temperature-resistant composite clean fracturing fluid, its components and mass percentages are as follows:

[0048] Stearic acid amidopropyl dimethylamine 2%; sodium p-toluenesulfonate 1.5%; modified nanoparticles 2% and the balance of water.

[0049] The preparation method of the temperature-resistant composite clean fracturing fluid comprises the following steps:

[0050] (1) 4g particle size is 25nm, specific surface area is 300m 2 / g of ordinary hydrophilic nano-silica is dispersed in 200ml of toluene with an ultrasonic cleaner, and then 4.5g of trimellitic anhydride is added, and magnetically stirred at room temperature for 15 hours at a speed of 650 rpm to obtain modified trimellitic anhydride. Nanoparticle reaction solution.

[0051] (2) Put the trimellitic anhydride modified nano-particle reaction solution obtained in step (1) into a high-speed centrifuge for high-speed centrifugation, the rotating speed is 9000 rpm, and the centrifugation time is 30 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com