A multi-sensor based robot task teaching method and system

A multi-sensor, teaching method technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of no flexible construction error compensation, high price, unsatisfactory actual accuracy, etc., to achieve single-axis flexible position compensation, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

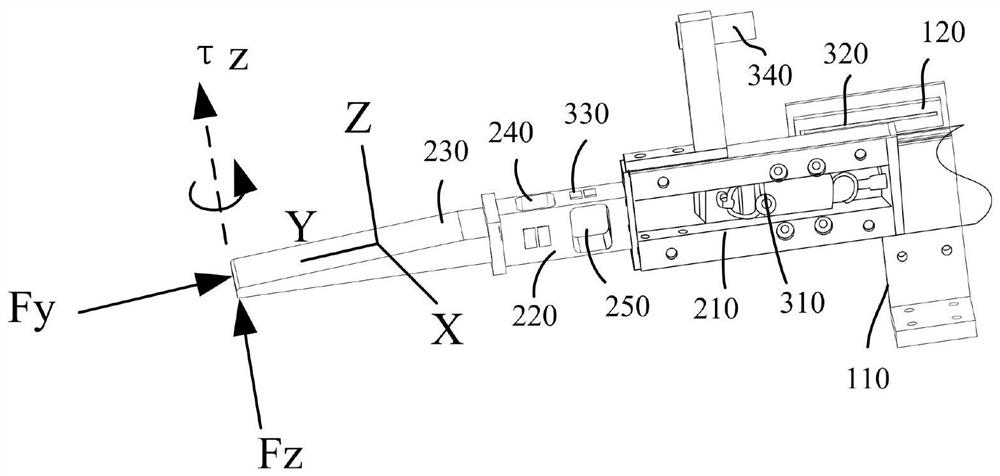

[0045] refer to Figure 1~4 , a robot task teaching system based on multi-sensors provided in this embodiment includes a fixing device, a sliding device movably connected with the fixing device, a sensing device arranged on the sliding device, and a control means and drive means 500;

[0046] The fixing device includes a fixing base 110, a linear slide rail 120 arranged on the fixing base 110;

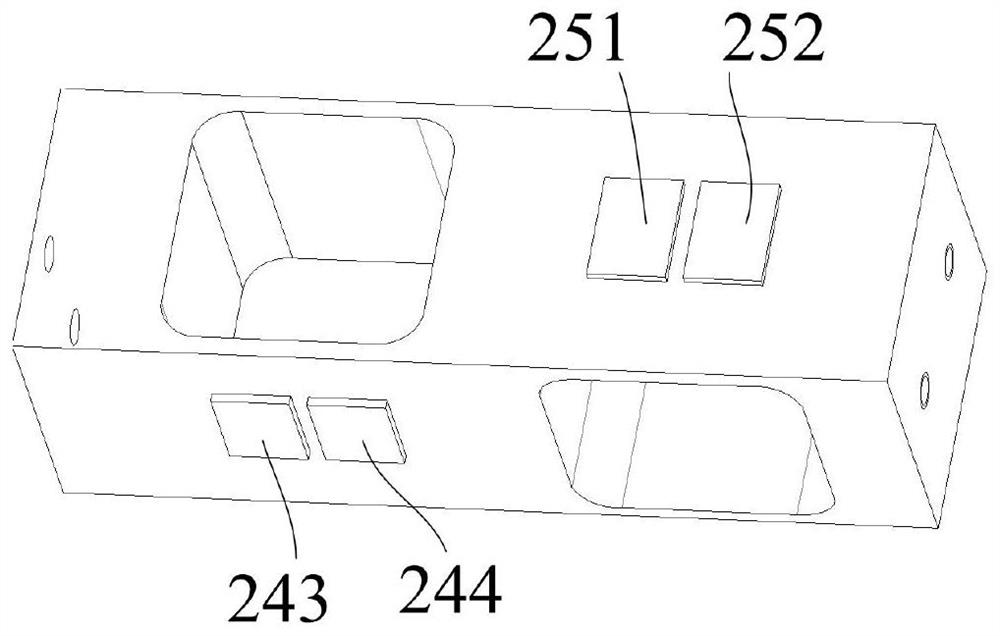

[0047] The sliding device includes a sliding platform 210 clamped on the linear slide rail 120, a structural member 220 fixedly connected to the sliding platform 210, and an end member 230 fixedly connected to the other end of the structural member 220;

[0048] The sensing device includes an elastic device 310 connecting the fixed base 110 and the sliding platform 210, a linear position sensor 320 arranged on the linear slide rail 120 and the sliding platform 210, and a linear position sensor 320 arranged on the structure The bridge circuit 330 on the part 220, the visual sensor 340...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com