Production method of insulation plate

A production method and technology of thermal insulation boards, which are applied in the direction of ceramic forming machines and manufacturing tools, can solve the problems that thermal insulation boards cannot be formed at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for producing a thermal insulation board.

[0046] The production method of the insulation board comprises:

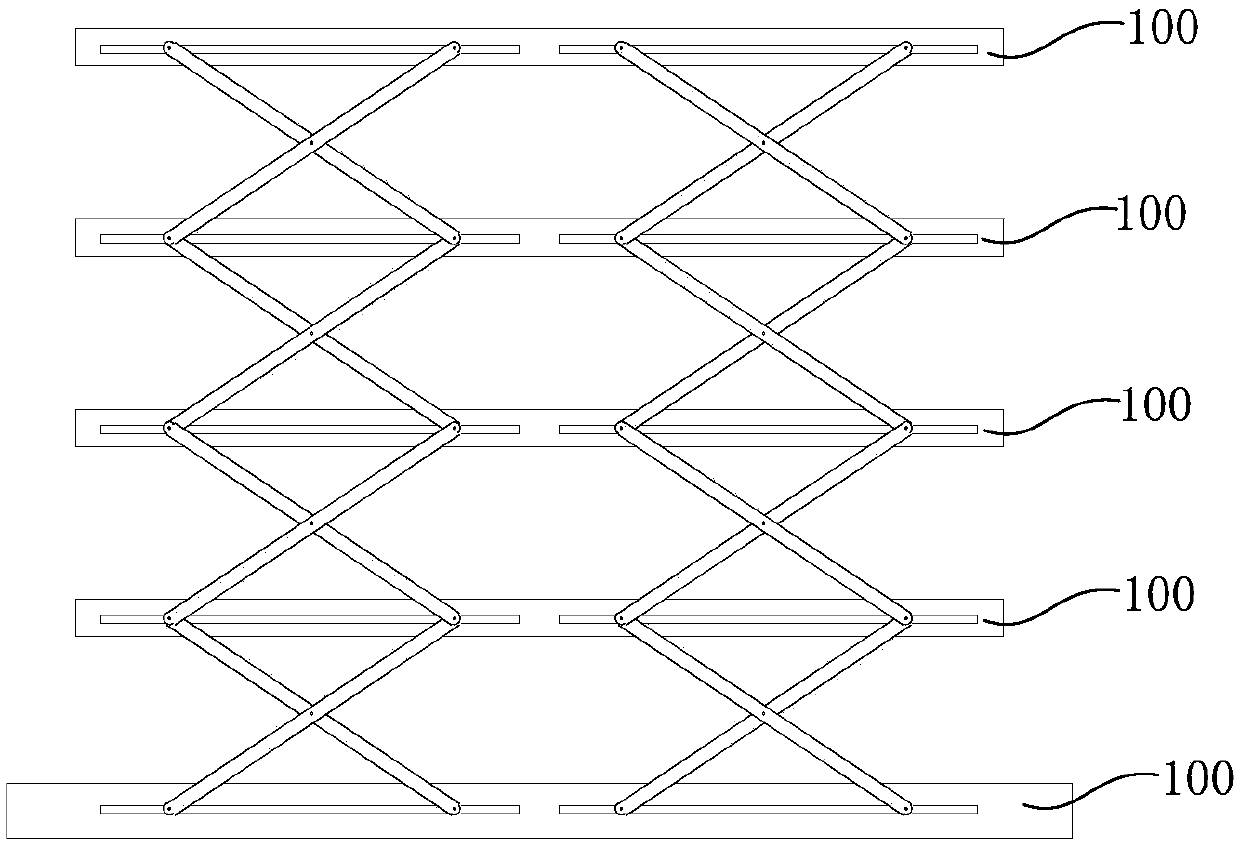

[0047] laying step: laying the raw material between adjacent pressing plates 100;

[0048] Pressing step: the adjacent press plates 100 are closed to press the raw material into a plate; and

[0049] Taking out step: open the adjacent pressing plate 100, and take off the forming plate.

[0050] Raw materials are laid between adjacent pressing plates 100, and when the adjacent pressing plates 100 are closed, the raw materials are pressed into a plate. When the raw material is pressed by the pressing plate 100, each part of the raw material is extruded at the same time, and each part of the plate is formed at the same time, so as to ensure that the forming quality of each part is consistent.

[0051] Specifically, the board pressing mechanism can be provided with two pressing plates 100, each time pressing to form a heat insula...

Embodiment 2

[0083] This embodiment provides a method for producing a thermal insulation board.

[0084] The production method of the insulation board comprises:

[0085] laying step: laying the raw material between adjacent pressing plates 100;

[0086] Pressing step: the adjacent press plates 100 are closed to press the raw material into a plate; and

[0087] Taking out step: open the adjacent pressing plate 100, and take off the forming plate.

[0088] Raw materials are laid between adjacent pressing plates 100, and when the adjacent pressing plates 100 are closed, the raw materials are pressed into a plate. When the raw material is pressed by the pressing plate 100, each part of the raw material is extruded at the same time, and each part of the plate is formed at the same time, so as to ensure that the forming quality of each part is consistent.

[0089] Specifically, the board pressing mechanism can be provided with two pressing plates 100, each time pressing to form a heat insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com