Gas injection and production method for communicating well salt cavern gas storage

A technology of gas injection and production and gas storage, which is applied in the fields of mining fluids, mining devices, mining equipment, etc., can solve the problems of long construction period, large proportion of bottom gas, and easy reduction of the volume of salt caverns, so as to improve the use efficiency, The effect of slowing down volume reduction and improving geological stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the rock salt mining area, the construction of the salt cavern gas storage was completed by using two connected wells, Company 1 and Company 2. The distance between the wellheads of the two salt wells is 220m; The well can be used to store natural gas with a solution cavity volume of 400,000 m 3 , the maximum diameter of the dissolution cavity is 65m, and the depth range of the dissolution cavity is 1080-1280m; the depth range of the dissolution cavity of Well Lian 2 is 1270-1280m; the depth range of the connecting channel 8 is 1280-1290m.

[0038] In company 1, there are Φ177.8mm injection-production string 5 and Φ114.3mm cavitation string 6 inserted into the injection-production string. 28m; Lian 2 well is equipped with a Φ177.8mm brine injection string 7.

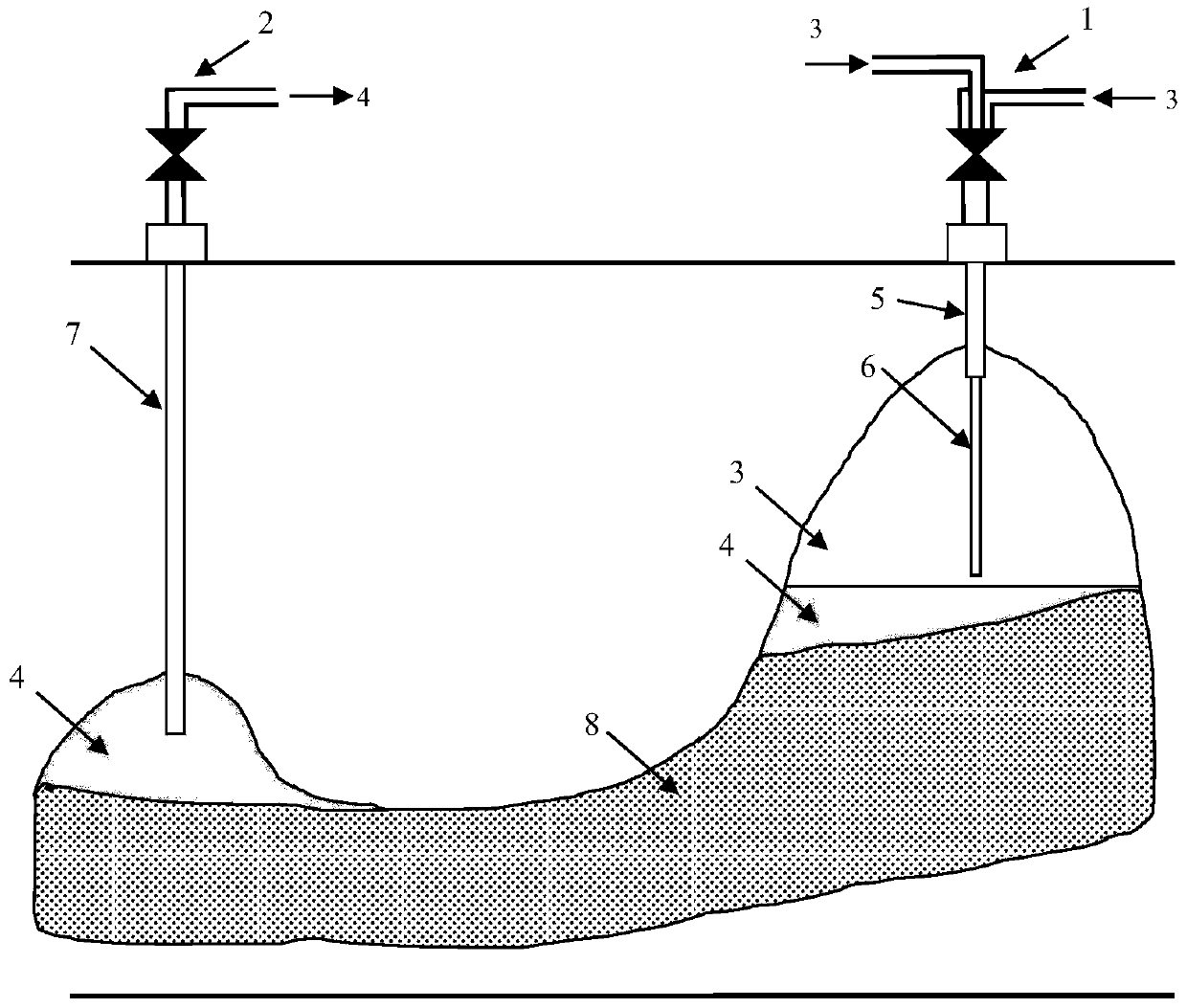

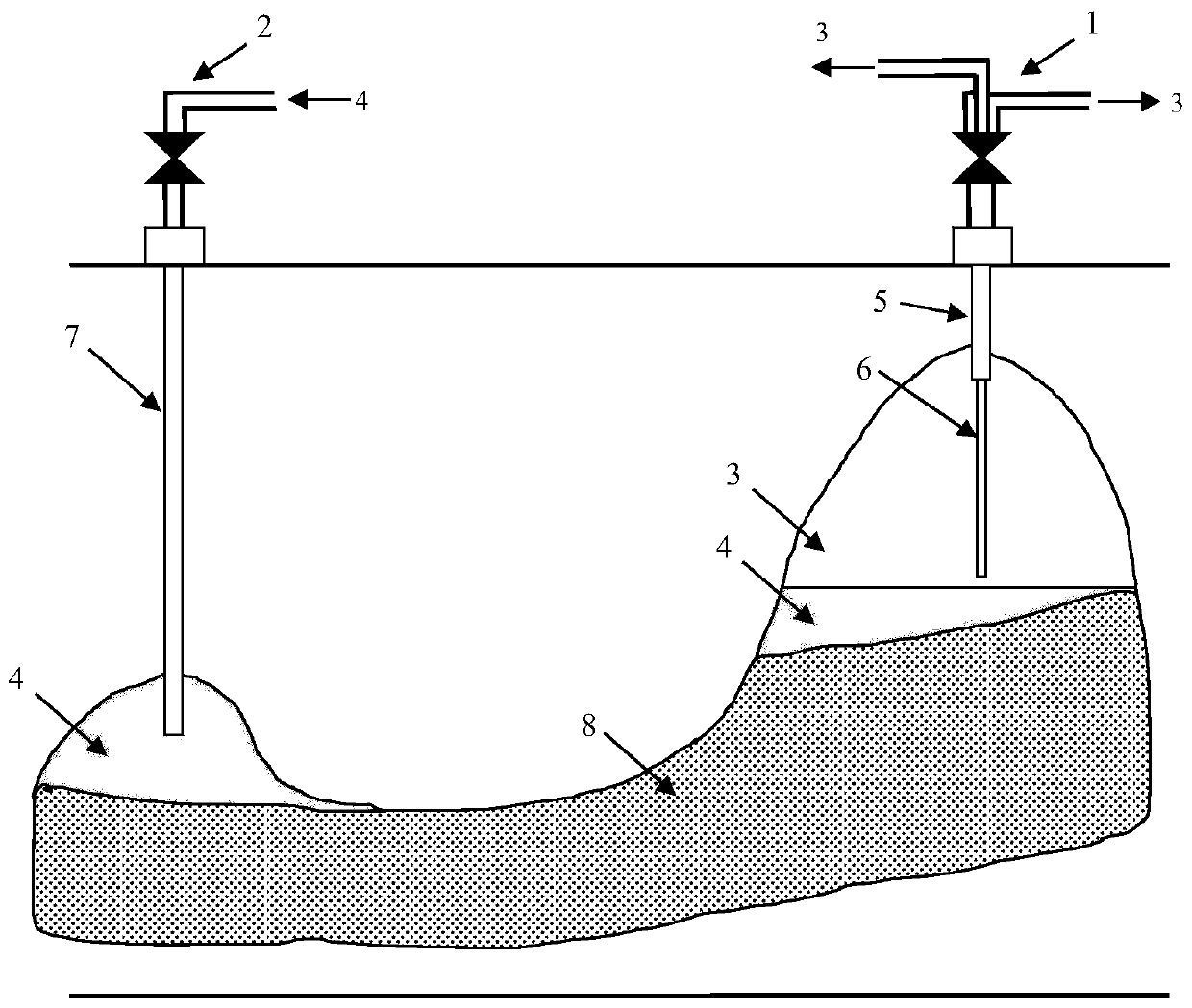

[0039] During the gas injection phase (such as figure 1 shown), the natural gas is injected into the gas storage at the same time through the injection-production string and cavity-making string of Well Lian ...

Embodiment 2

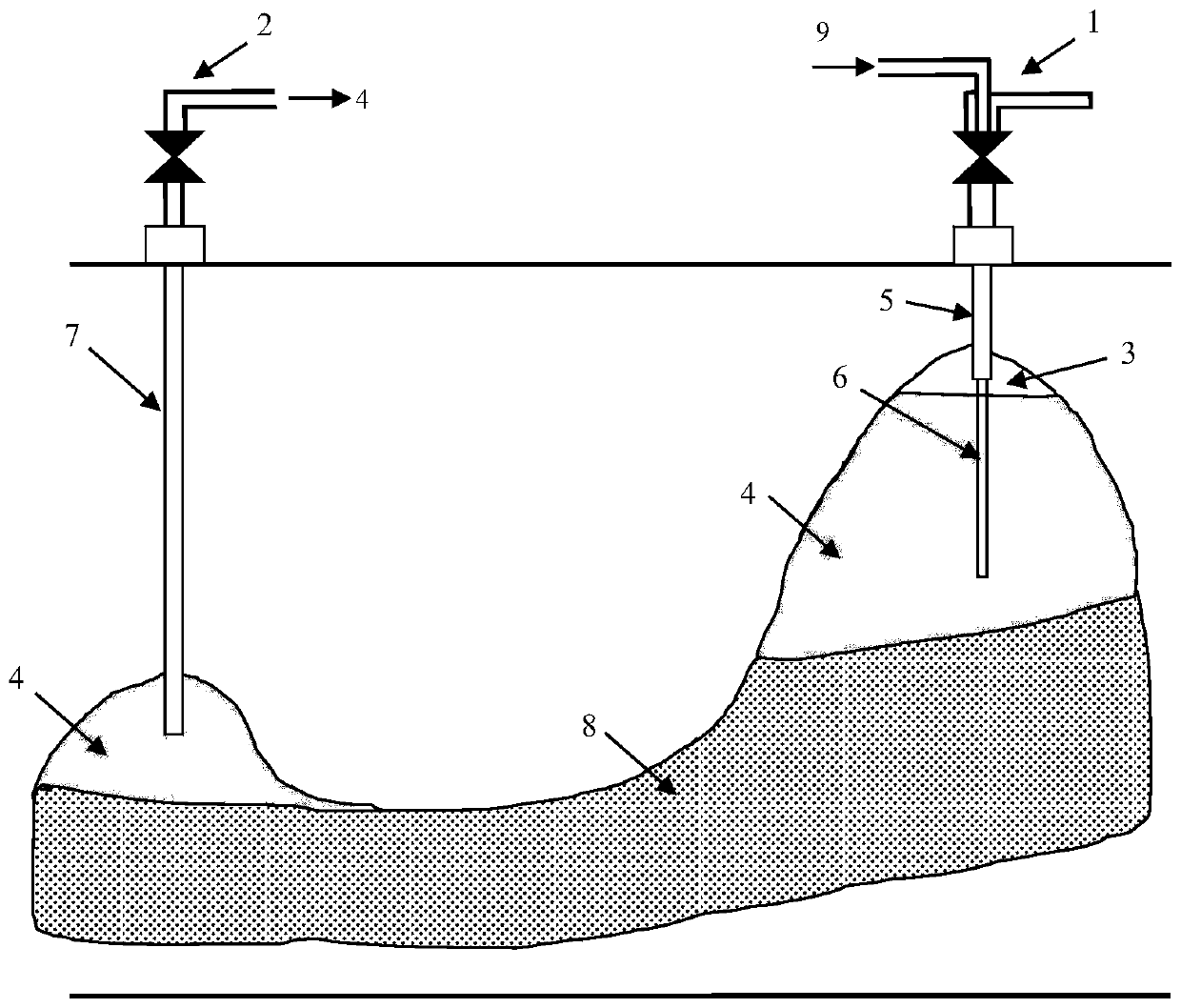

[0044] In the rock-salt mining area, the construction of the salt cavern gas storage was completed by using three interconnected wells, namely, Company 1, Company 2 and Company 3. The distance between the wellheads of two adjacent salt wells was 200m; Wells are used as brine injection and drainage wells; among them, the total volume of dissolved cavities in Wells Lian 1 and Lian 3 is 700,000 m 3 , the maximum diameter of the dissolution cavity is 70m, the depth range of the dissolution cavity of the two salt wells is 1100-1300m; the volume of the dissolution cavity of Lian 2 well is 20,000 m 3 , the depth range of the dissolution cavity is 1275-1300m; the depth range of the connecting channel 8 is 1300-1312m.

[0045] In wells Lian 1 and Lian 3, there are Φ177.8mm injection-production strings 5 and Φ114.3mm cavitation strings 6 inserted into the injection-production strings. The mouth distance is 30m; the Lian 2 well is equipped with a Φ177.8mm brine injection string 7.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com