Movable melt container

A container and melt technology, which is applied in the field of smelting melt containers, can solve the problems of laboriousness, easy occurrence of burns, scalds, etc., and achieve the effect of reducing burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

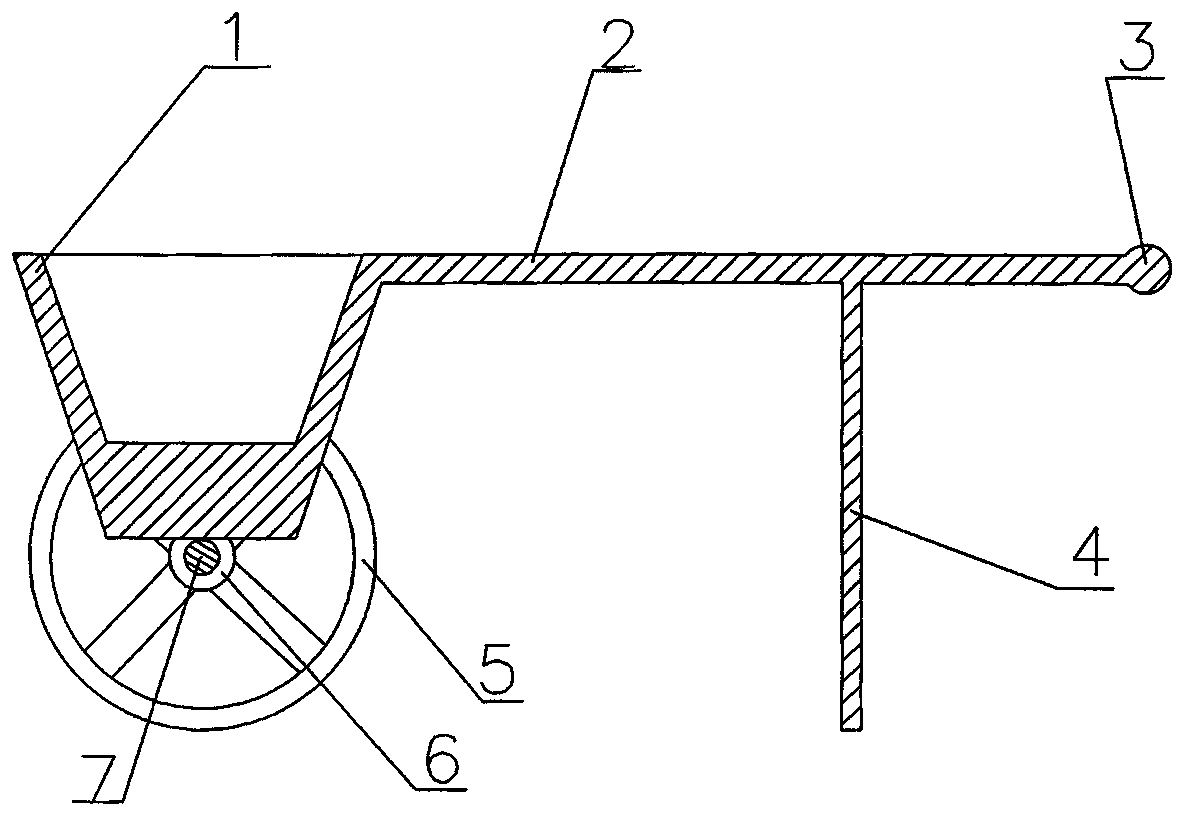

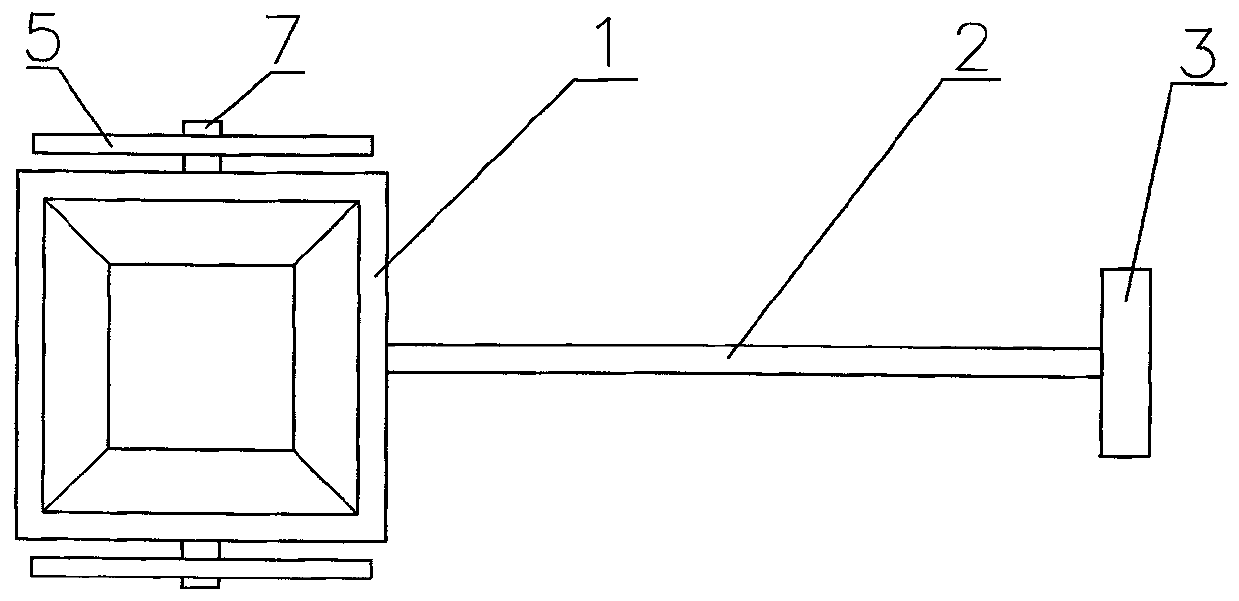

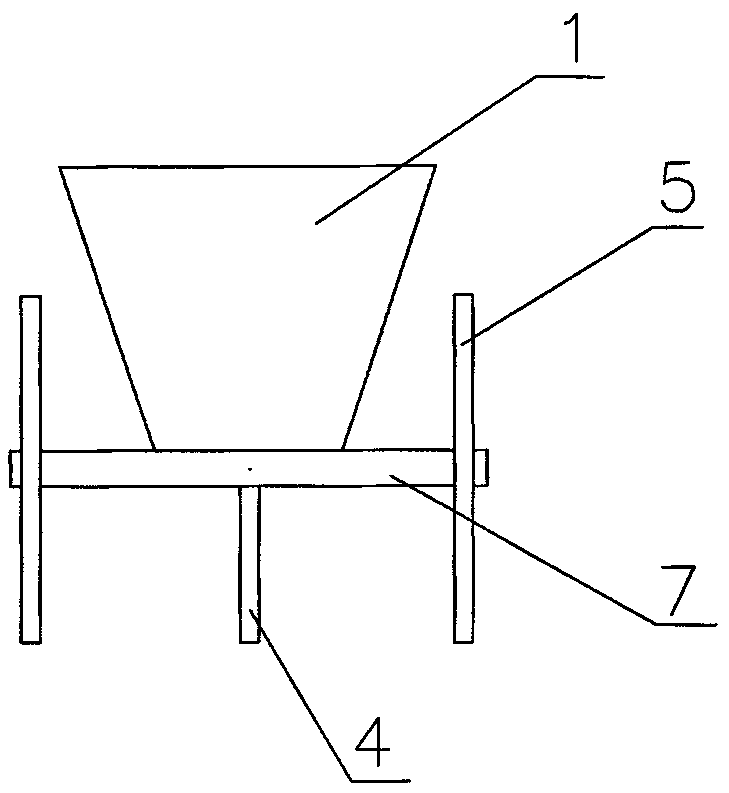

[0015] exist figure 1 , figure 2 , image 3 In the shown embodiment, the upper end of the container 1 is welded with a pull rod 2, the other end of the pull rod 2 is welded with a handle 3, the middle lower part of the pull rod 2 is welded with a leg 4, the bottom of the container 1 is welded with a shaft 7, and the wheel 5 passes through the bearing 6 Connected to both ends of shaft 7.

[0016] When in use, pour the smelting melt into the container 1. After it is full, pick up the handle 3 to lift the feet 4 off the ground, and then drive the container 1, shaft 7, bearing 6, and wheels 5 to move through the pull rod 2. After reaching the destination , the legs 4 touch the ground, and the container 1 is kept stable through the effects of the legs 4, the pull rods 2, the shaft 7, the bearings 6, and the wheels 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com