Feeding machine for food solid state fermentation

A solid-state fermentation and feeder technology, applied in food preparation, application, food science and other directions, can solve the problems of easy contamination of materials, high labor intensity of workers, low production efficiency, etc., to reduce burns, improve work efficiency, and facilitate Cooling and drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

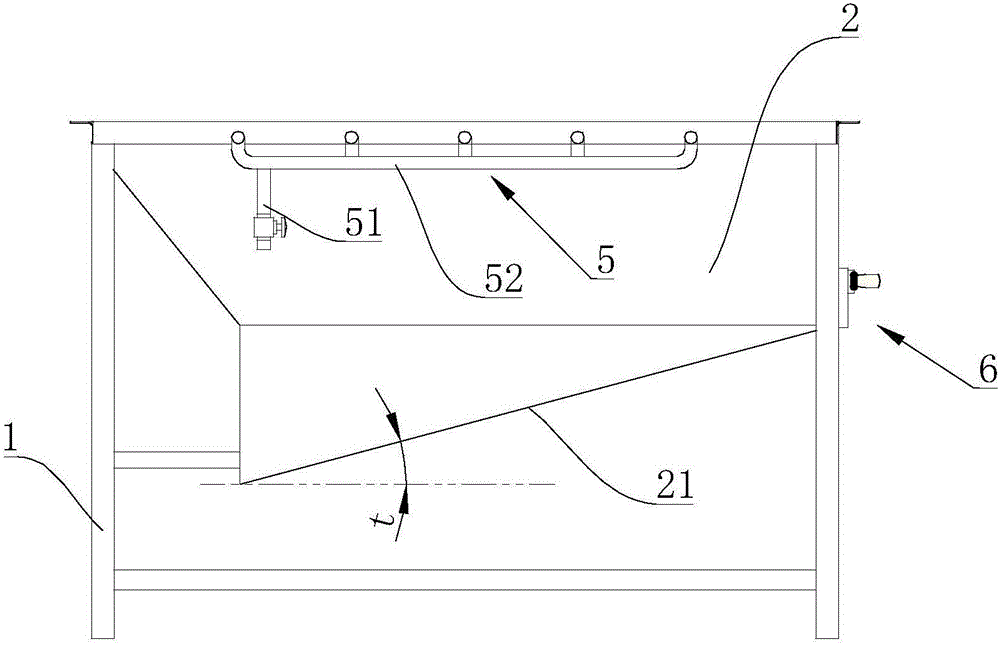

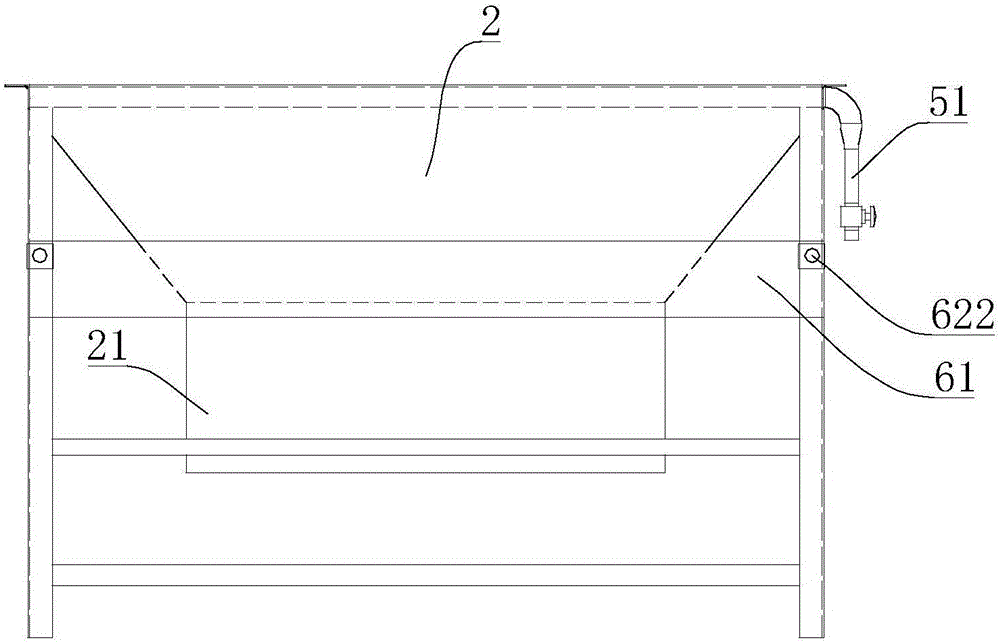

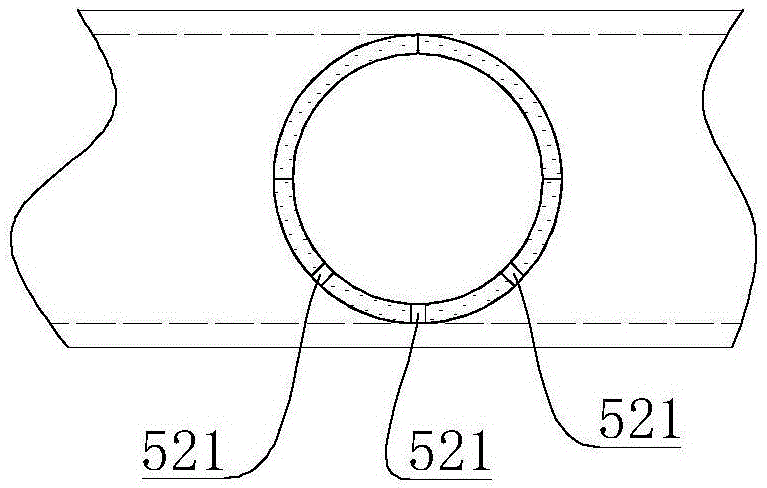

[0017] A feeder for solid-state fermentation of food, including a support frame 1, a silo 2 and a boiling water supply system 5, the silo 2 is set on the support frame 1, the upper part of the silo 2 is a feed inlet, and the lower part of the silo 2 is a The discharge port 21, the plane where the discharge port 21 is located is inclined, and the water discharge port of the boiling water supply system 5 points to the silo 2.

[0018] Such as Figure 1~2 Shown: the feeder used for food solid-state fermentation of the present invention, its support frame 1 is used to support components such as silo 2, and silo 2 is used for temporarily storing materials, and the upper part of silo 2 is a feeding port, and the lower part The discharge port 21 is used to cooperate with the material conveying device and output the material. For example, the discharge port 21 is facing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com