Double-roller gley soil reverse-rotation-type rotary tillage stubble burying machine

A technology of counter-rotating and rotary plowing knife rollers, applied in agricultural machinery, agricultural machinery and implements, shovels, etc., can solve the problems of easy entanglement of the knife shaft, shallow tillage depth and high energy consumption, and can solve the problems of entangled grass and missed tillage, volume Small, Compatible Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific structure and working principle of the present invention are described below in conjunction with the accompanying drawings:

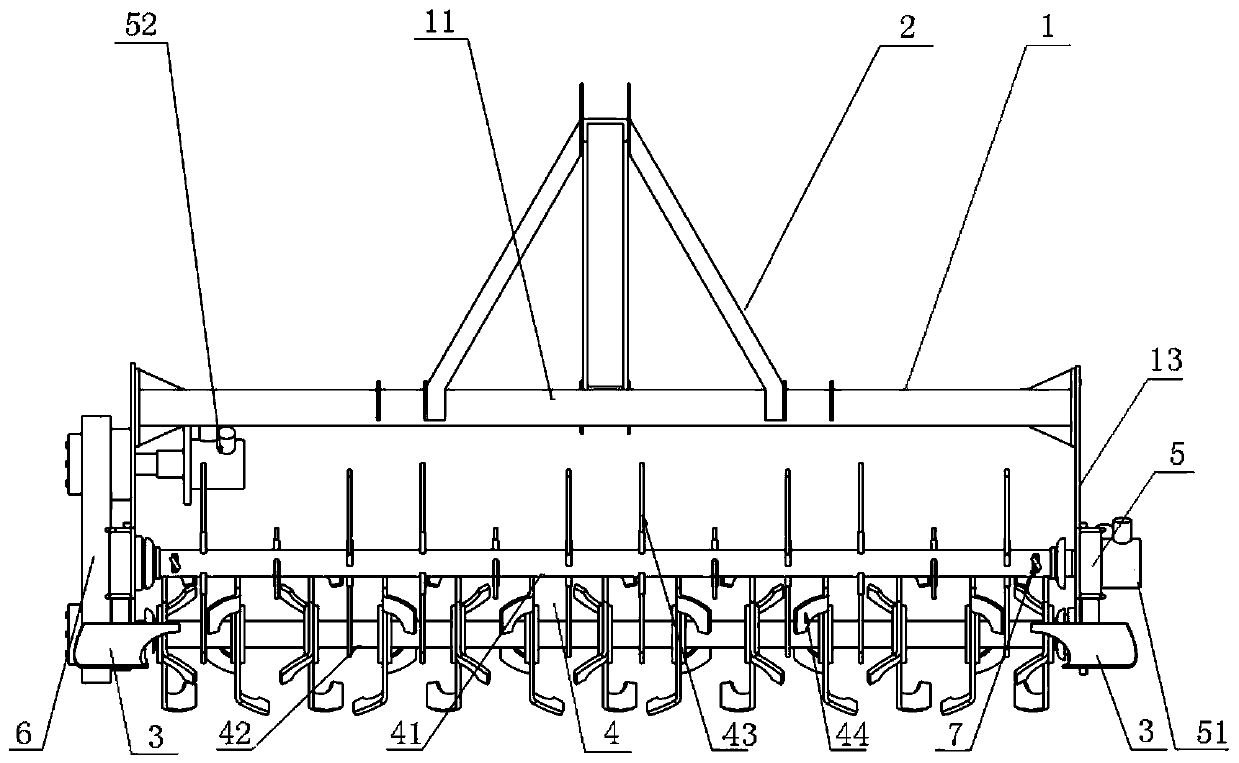

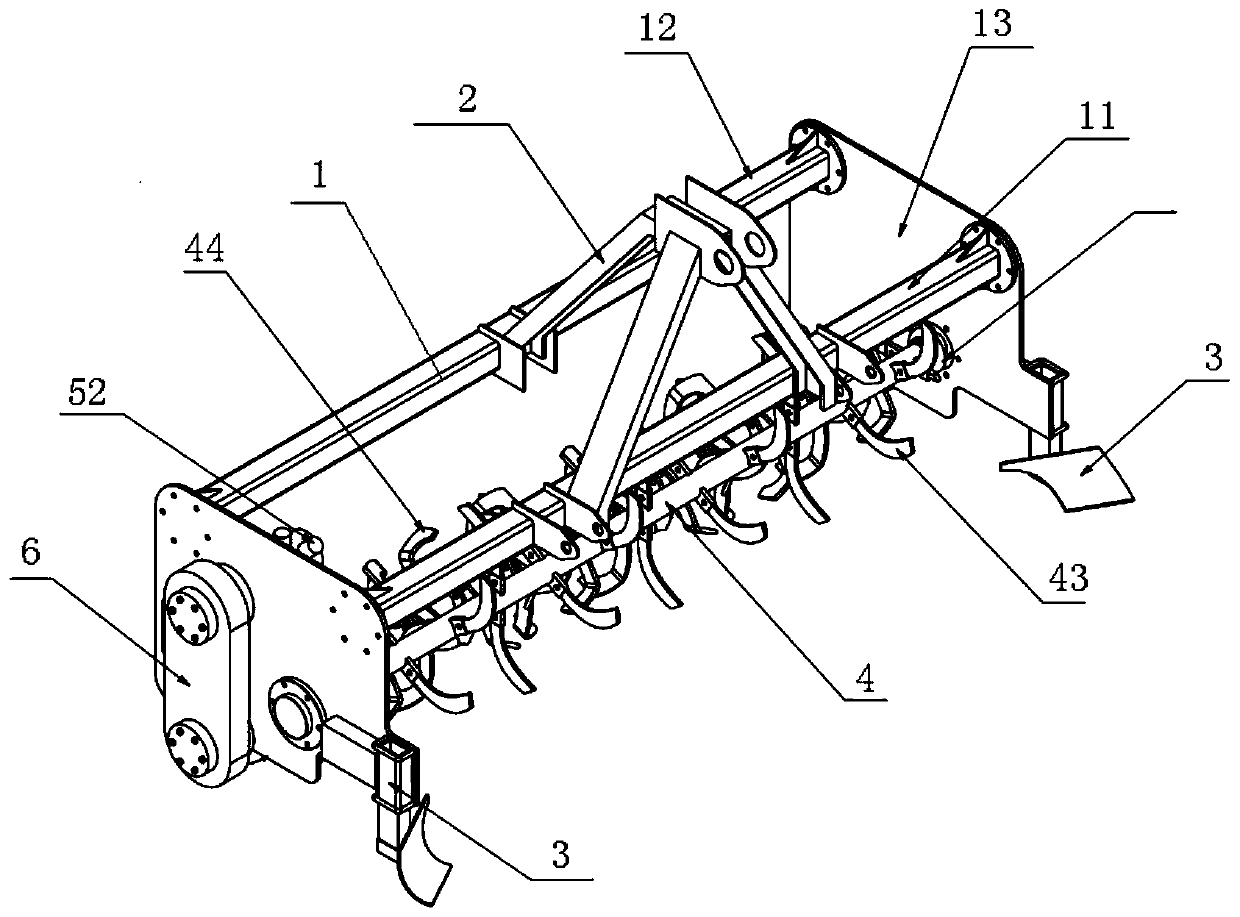

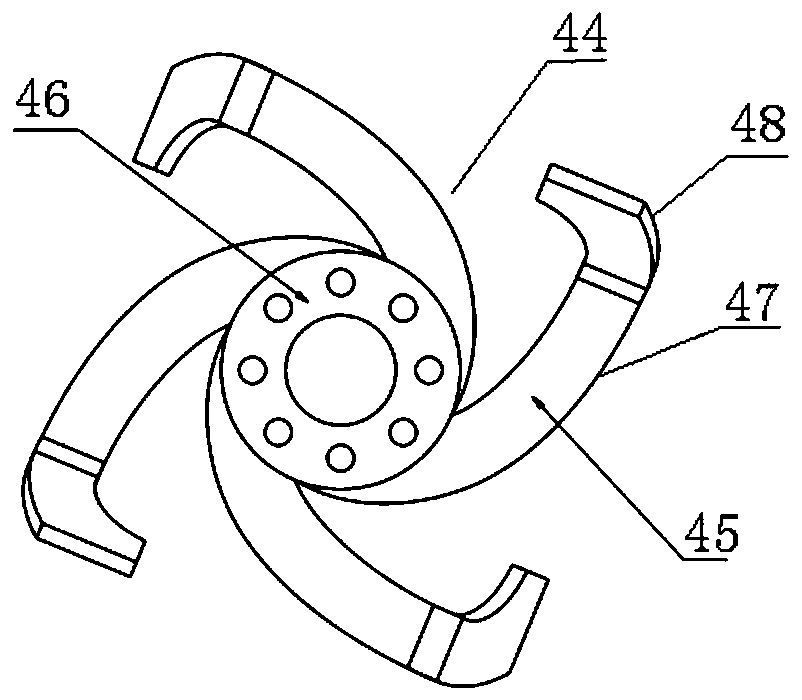

[0030] Such as figure 1 and 2 Shown: a double-roller submerged soil reverse-rotary rotary tillage and stubble embedding machine, the whole machine is composed of a frame 1, a triangular suspension 2, two furrow plows 3, a rotary tiller roller 4 and a motor 5. The frame 1 is composed of two side plates 13 and a front beam 11 and a rear beam 12 welded between the two side plates 13 . Two pins of the triangular suspension 2 are welded on the front beam 11, and the other pin is welded on the rear beam 12 for dragging the frame 1 on the tractor tail. Two furrowing plows 3 are respectively welded to the front ends of the two side plates 13 and are located at the bottom of the frame 1, and are used for digging the cultivated land on both sides when the rotary tiller and stubble embedding machine is moving, so that a part of the machine sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com