A Converter Aging Test System

An aging test and converter technology, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problem of not considering the difference in the demand of the converter, the difference in the requirements of different types and specifications of the converter filter and the voltage level and other problems to achieve the effect of meeting the aging test requirements, enhancing the aging adaptability, and reducing the system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

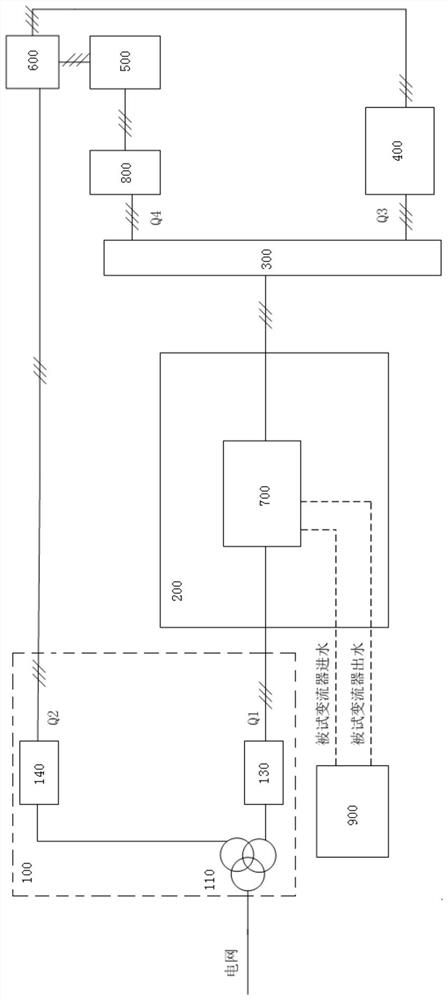

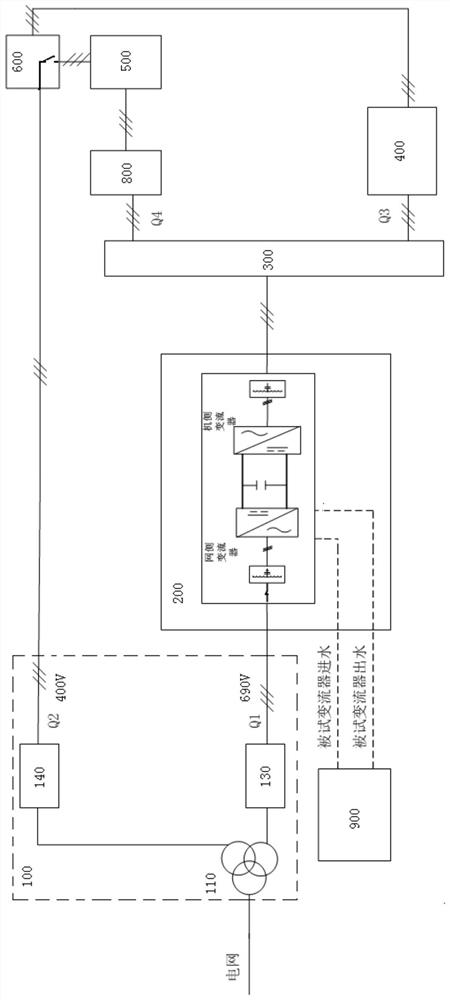

[0033] As mentioned above, aiming at the problem in the prior art that converters of different types and specifications cannot share an aging system according to different aging types, the present invention provides a new converter aging test system. Such as figure 1 As shown, the converter aging test system mainly includes a transformer module 100 , a temperature-controlled aging box 200 , an output selection switch 300 , a motor pairing platform 400 , a filter 500 and a feedback selection switch 600 . in:

[0034] The input terminal of the transformer module 100 is used to connect to the three-phase power grid, and the output terminal of the transformer module 100 includes at least two voltage taps Q1 and Q2, so as to meet the voltage level requirements of different converters. Preferably, the voltage level taps output by the transformer module 100 must at least meet the requirements of three voltage levels.

[0035] For example, the transformer module 100 can be configure...

Embodiment 2

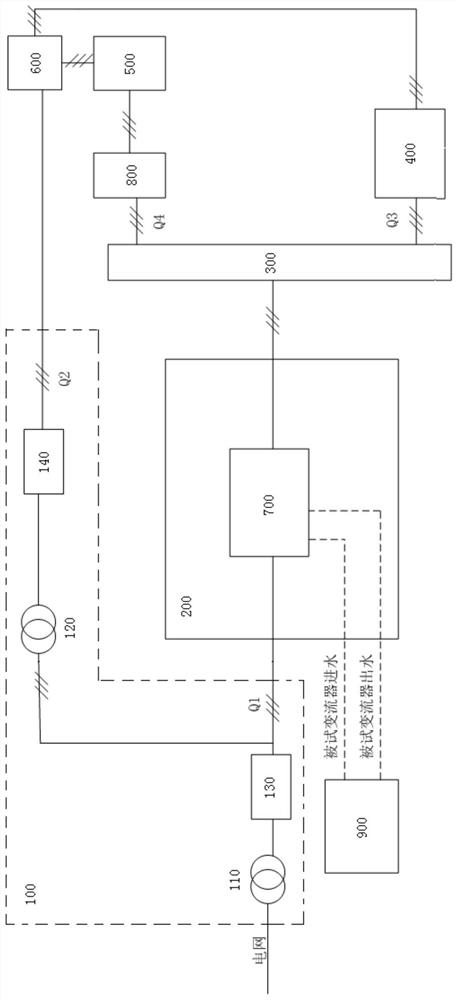

[0045] Such as figure 2 As shown, in Embodiment 2 of the present invention, another form of transformer module 100 is adopted, which can achieve the same technical effect.

[0046] Specifically, the transformer module 110 includes a first transformer 110 and a second transformer 120, wherein:

[0047] The primary side of the first transformer 110 (that is, the input end of the transformer module 100) is connected to the three-phase grid, and the secondary side of the first transformer 110 is connected to the grid-side input end of the tested converter 700 through the first voltage level selection switch 130;

[0048] The primary side of the second transformer 120 is connected to the output terminal of the feedback selection switch 600 through the second voltage level selection switch, and the secondary side of the second transformer 120 is connected to the grid-side input terminal of the tested converter 700 .

[0049] Moreover, the voltage level of the secondary side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com