Bending machine for forming corrugations in sheet metal and method of use

A technology for bending machines and metal plates, which is applied in the field of bending machines and can solve the problems of increasing the overall size of the bending machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

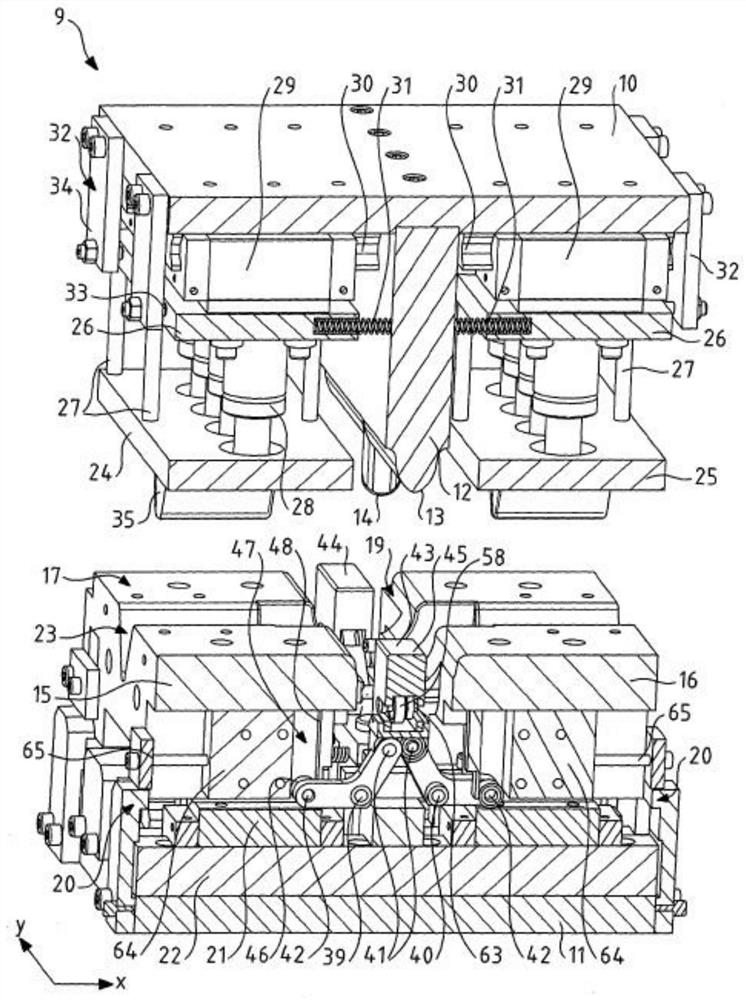

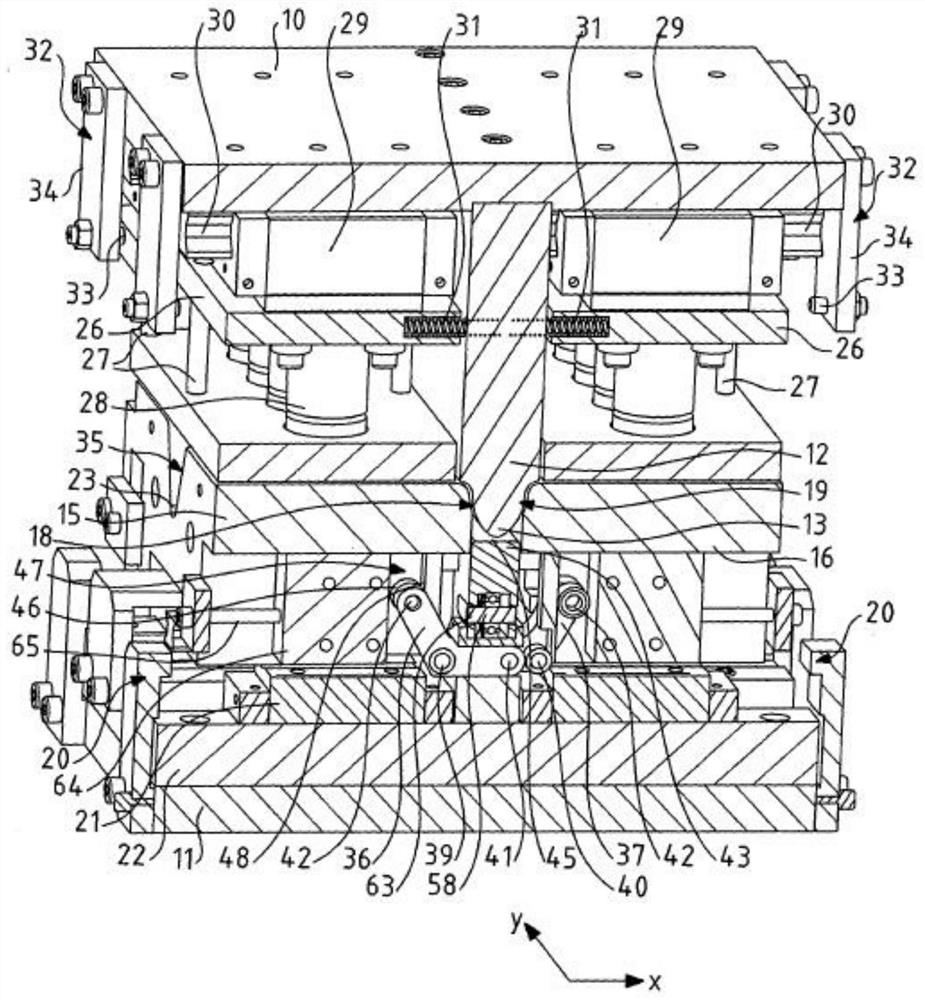

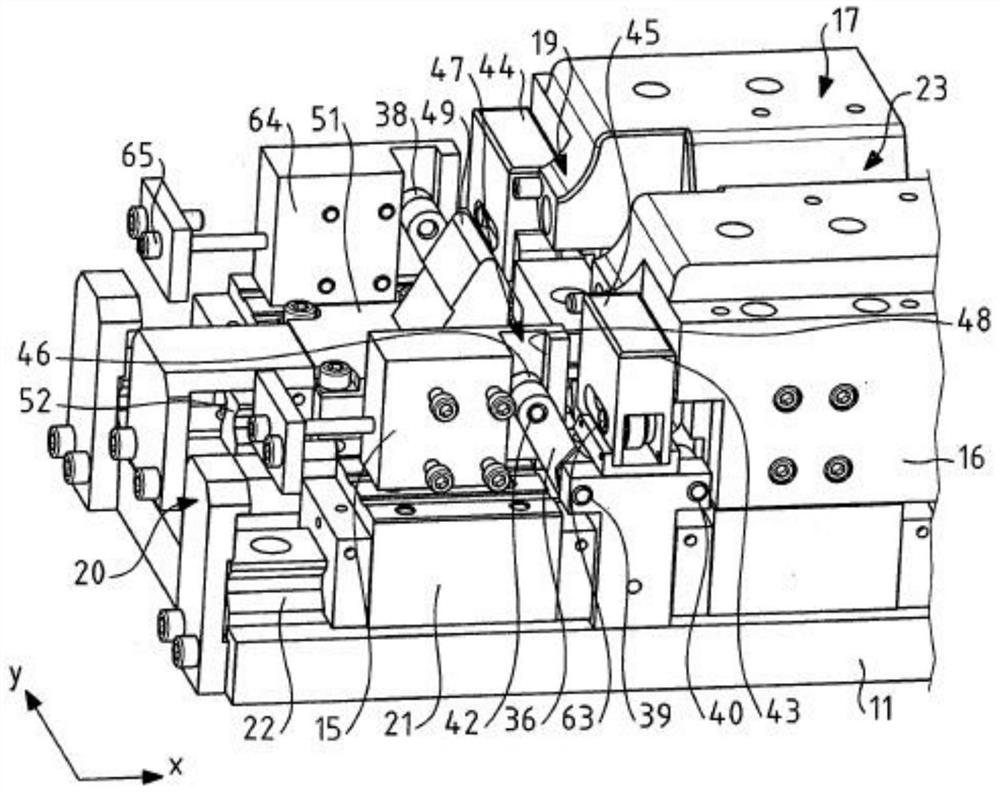

[0093] Figure 9 Shown is a corrugated metal sheet 1 for forming a fluid tight membrane for a storage tank for a cryogenic fluid such as liquefied natural gas.

[0094] Said rectangular metal plate 1 comprises a first series of parallel, so-called low corrugations 2, extending in the y-direction from one edge of the plate to the other, and a second series of parallel, so-called high corrugations 3, of high The corrugations 3 extend from one edge of the metal plate 1 to the other in the x-direction. The directions x and y of the series of ripples are perpendicular. The corrugations 2, 3 protrude, for example, from the inner surface side of the metal plate 1 to come into contact with the fluid contained in the tank. Here, the sides of the metal plate 1 are parallel to the corrugations 2,3. It is worth noting that the terms "high" and "low" have relative meanings and mean that the height of the so-called low corrugations 2 is lower than the height of the so-called high corruga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com