Method for manufacturing double-sided circuit substrate and double-sided circuit substrate

A technology of circuit substrate and manufacturing method, which is applied in the direction of printed circuit manufacturing, circuit, printed circuit, etc., can solve the problems such as unable to present images, and achieve the effect of avoiding electrical connection failure and avoiding the increase of shading area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

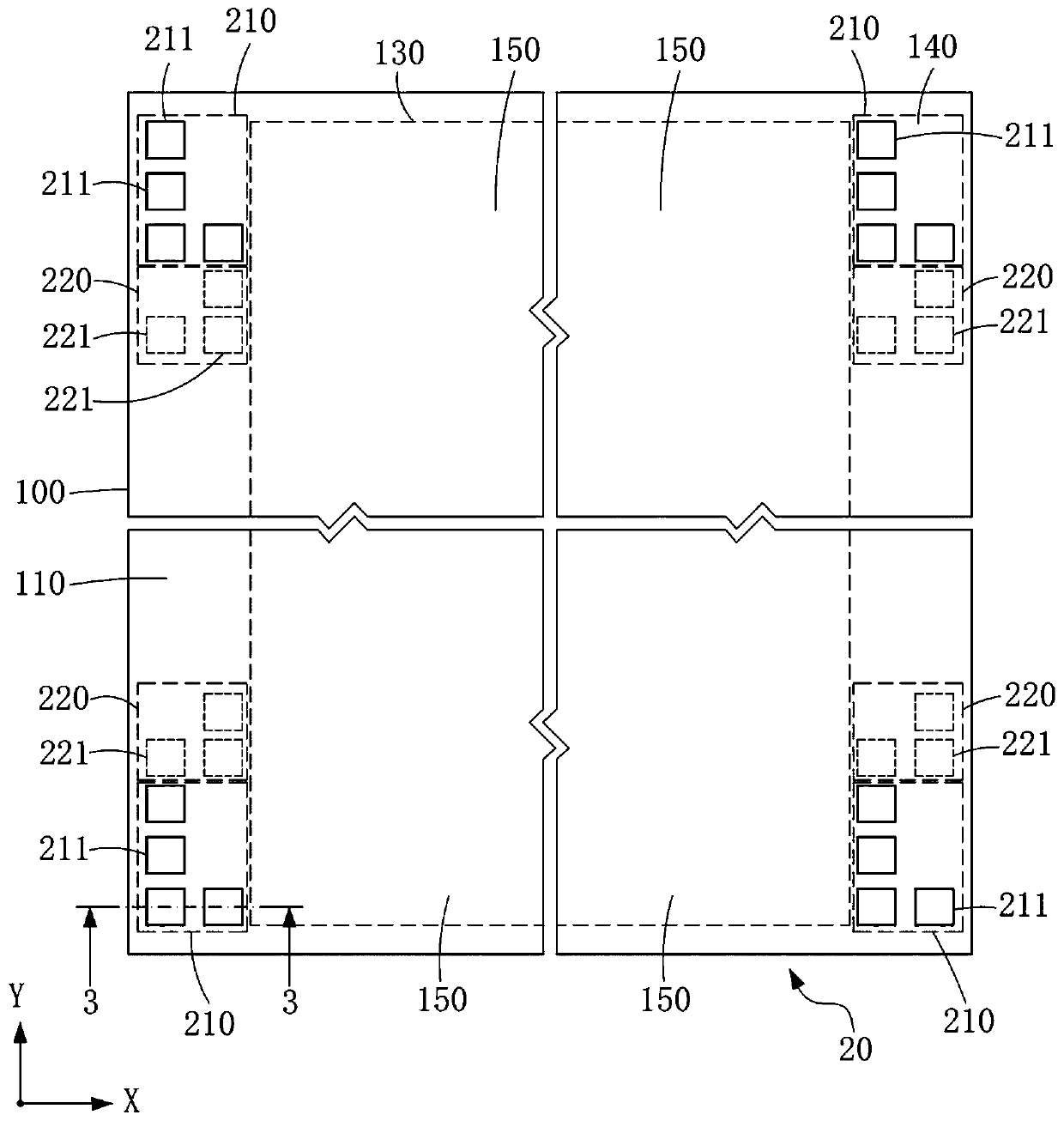

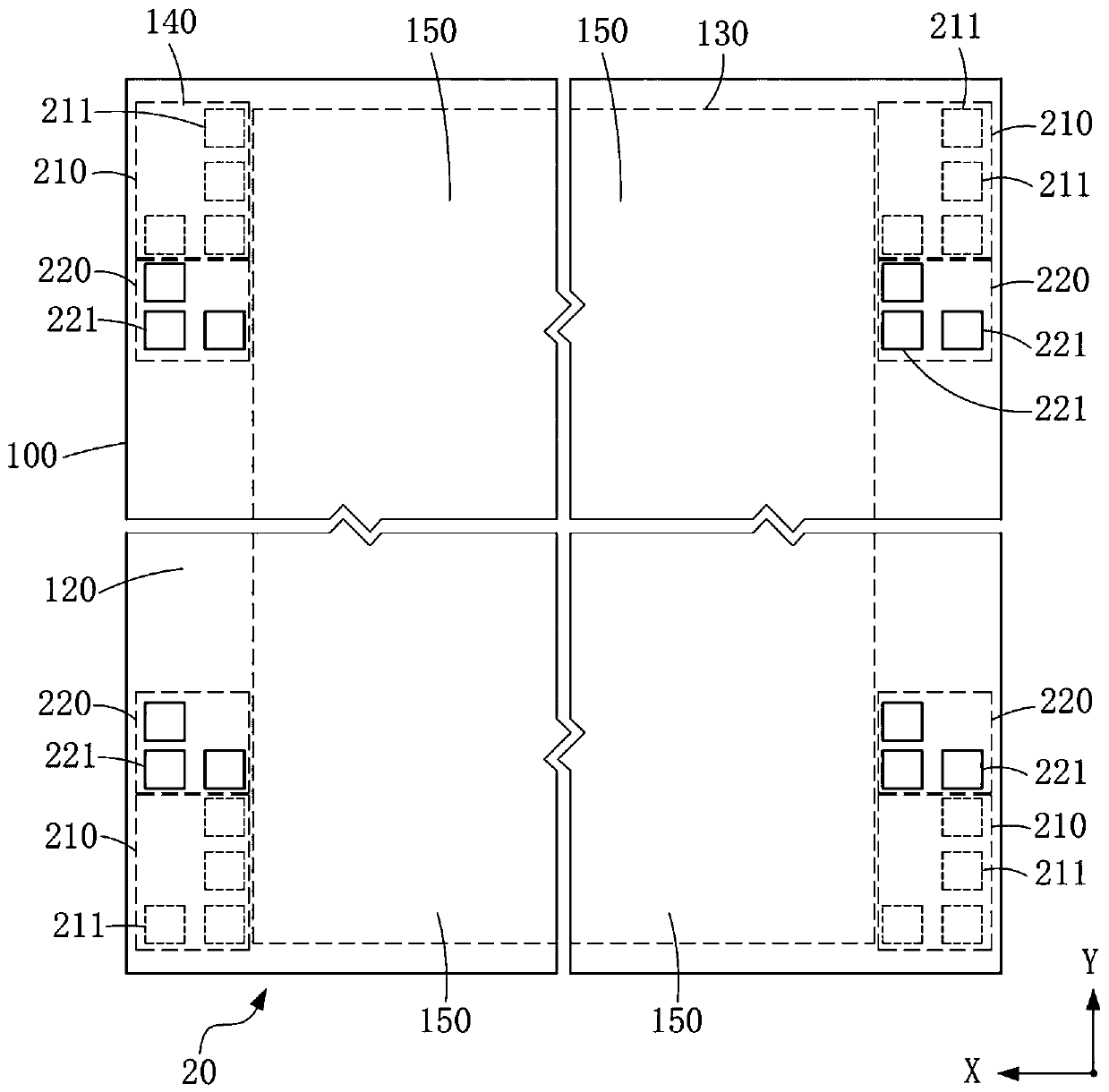

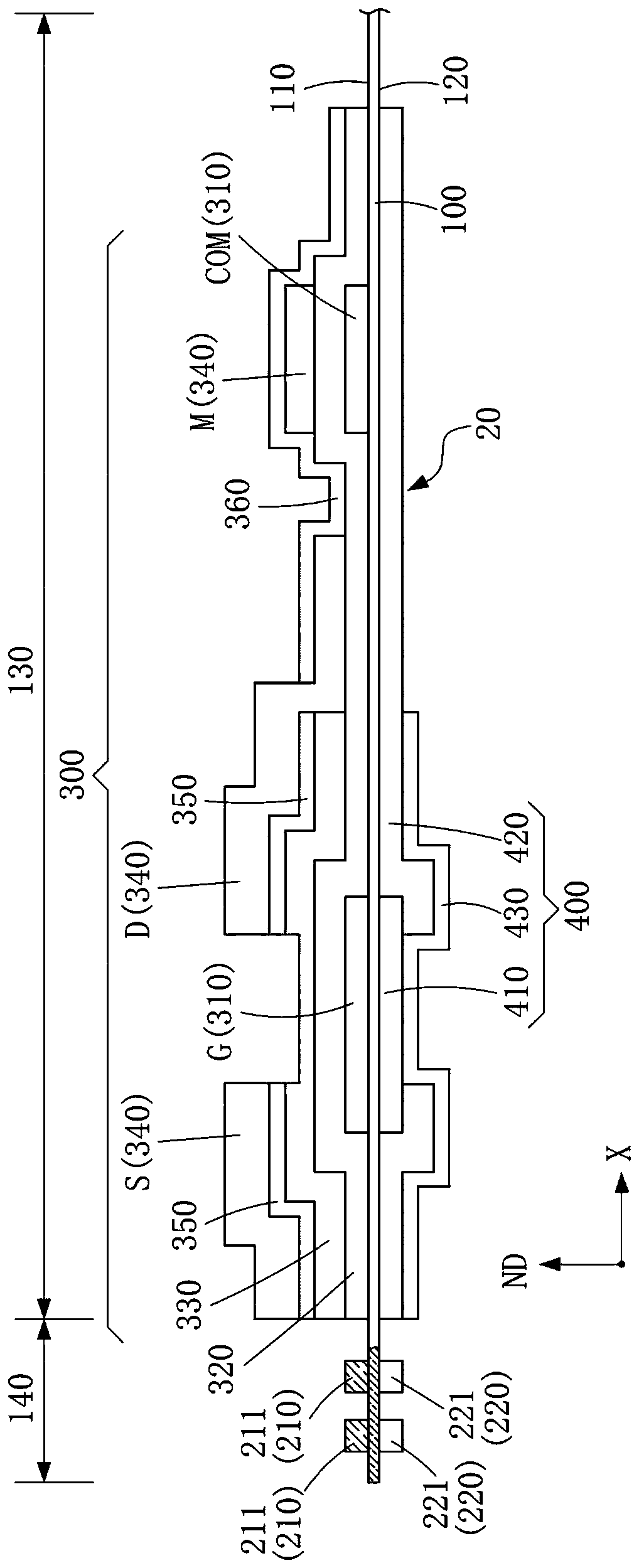

[0068] Please refer tofigure 1 and figure 2 , figure 1 Shown is a schematic top view of a double-sided circuit substrate 20 according to an embodiment of the present invention, figure 2 shown as figure 1 A schematic bottom view of the double-sided circuit substrate 20 of FIG. In this embodiment, the double-sided circuit substrate 20 is used to make a display panel, but it is not limited thereto. The double-sided circuit substrate 20 includes a substrate 100 , a first alignment mark 210 and a second alignment mark 220 . The substrate 100 includes a first surface 110 and a second surface 120 , and the first surface 110 and the second surface 120 are opposite to each other. The first alignment mark 210 is located on the first surface 110 , and the second alignment mark 220 is located on the second surface 120 . In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com