Tool and method for installing seal

A technology of seals and annular seals, applied in the direction of manufacturing tools, sealing surface connections, passing components, etc., can solve the problems of difficult detection of seals and damage to sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

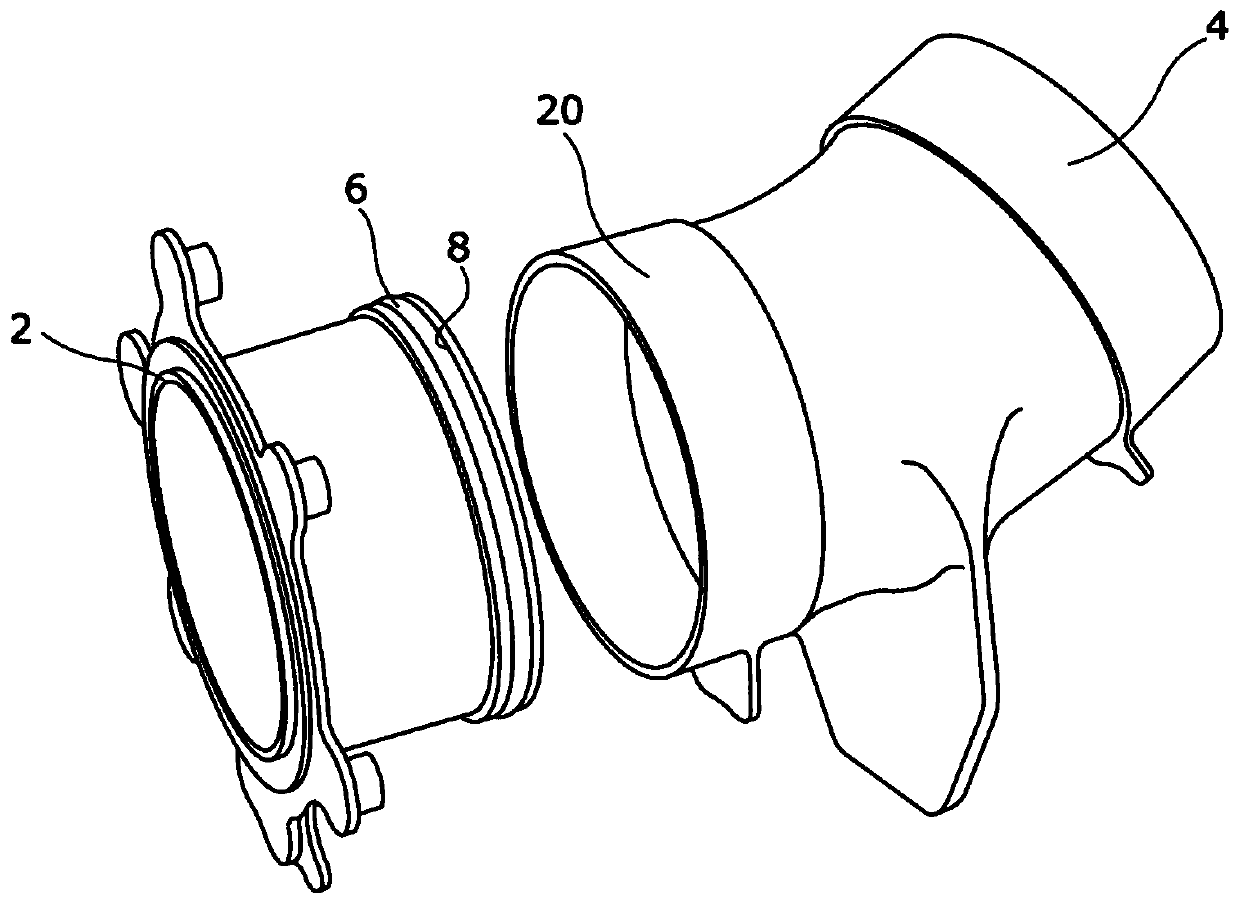

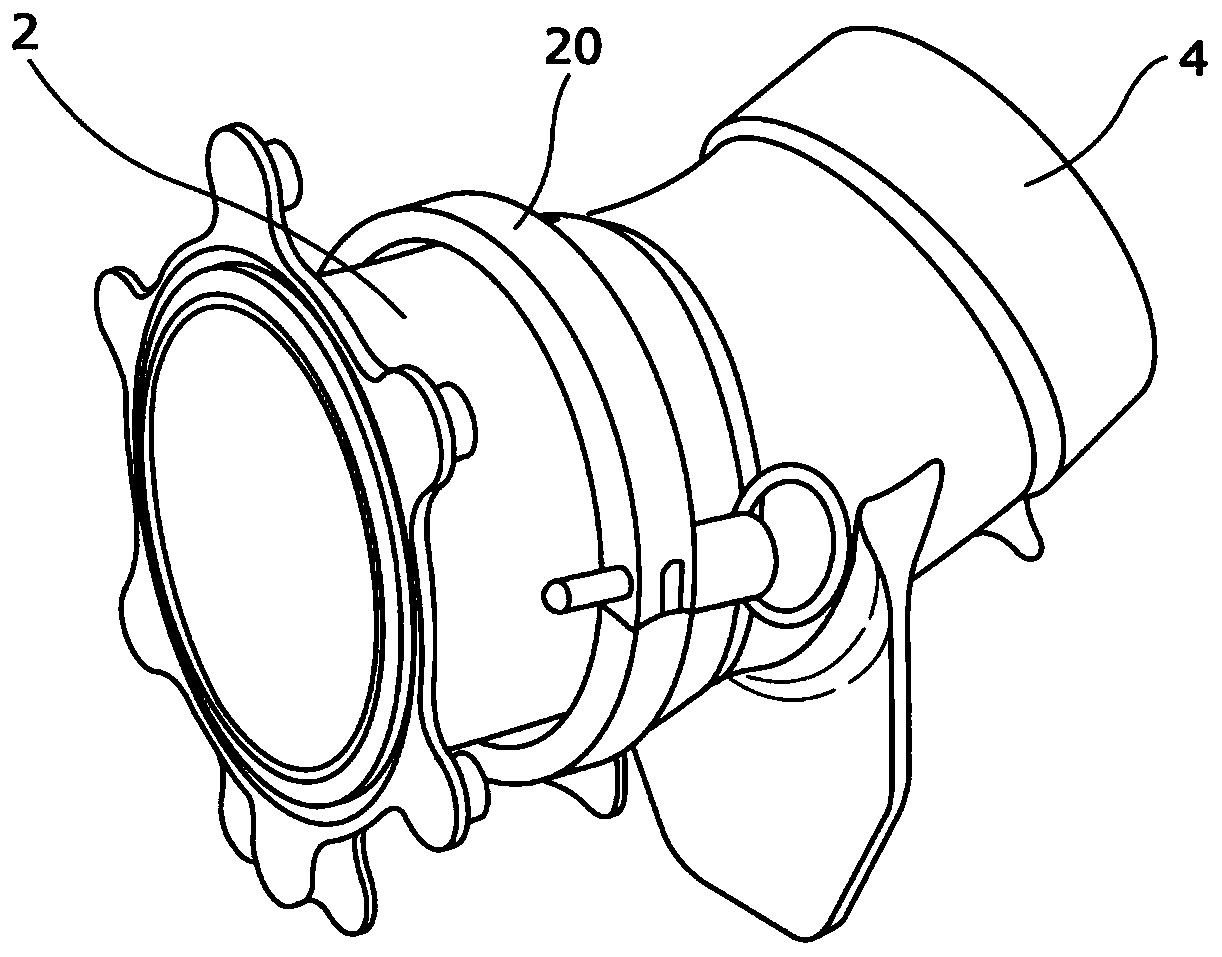

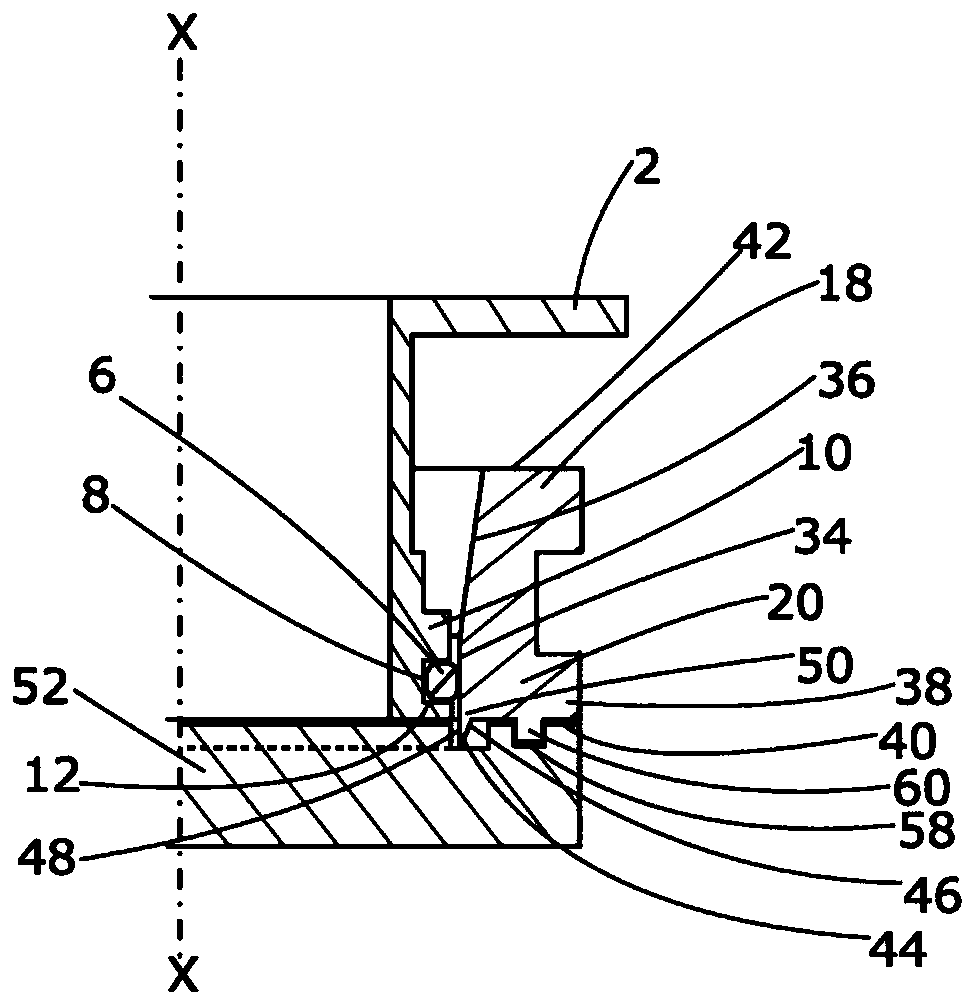

[0039] Such as figure 1 and figure 2 As shown, the invention relates to the coupling of any type of male tubular part 2 in a female tubular part 4, and more particularly to the installation of an annular seal 6 between the coupled tubular parts. The term "tubular part" is to be understood in a very general sense, as it equally covers conduits, pipe fittings, end fittings, connectors, etc., i.e. any Tubular elements. Tubular parts are intended for use in any type of application, with any type of fluid, such as water, oil, air, oxygen, etc. The term "annular" covers the general definition, ie any form which is closed on itself, for example that of a torus. The seal may have any type of cross-section; the seal may be, for example, a seal of O-shaped, D-shaped, four-lobed cross-section or the like. Seals can be lubricated or unlubricated.

[0040] exist Figure 1 to Figure 19In the illustrated embodiment, the example used is that of an O-ring (ring of circular cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com