Off-line Compensation Method for Five-axis Machining Tool Deformation Error Based on Least Square Method

A least square method and deformation error technology, applied in the field of mechanical machining, can solve the problem of low efficiency of tool track offline compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

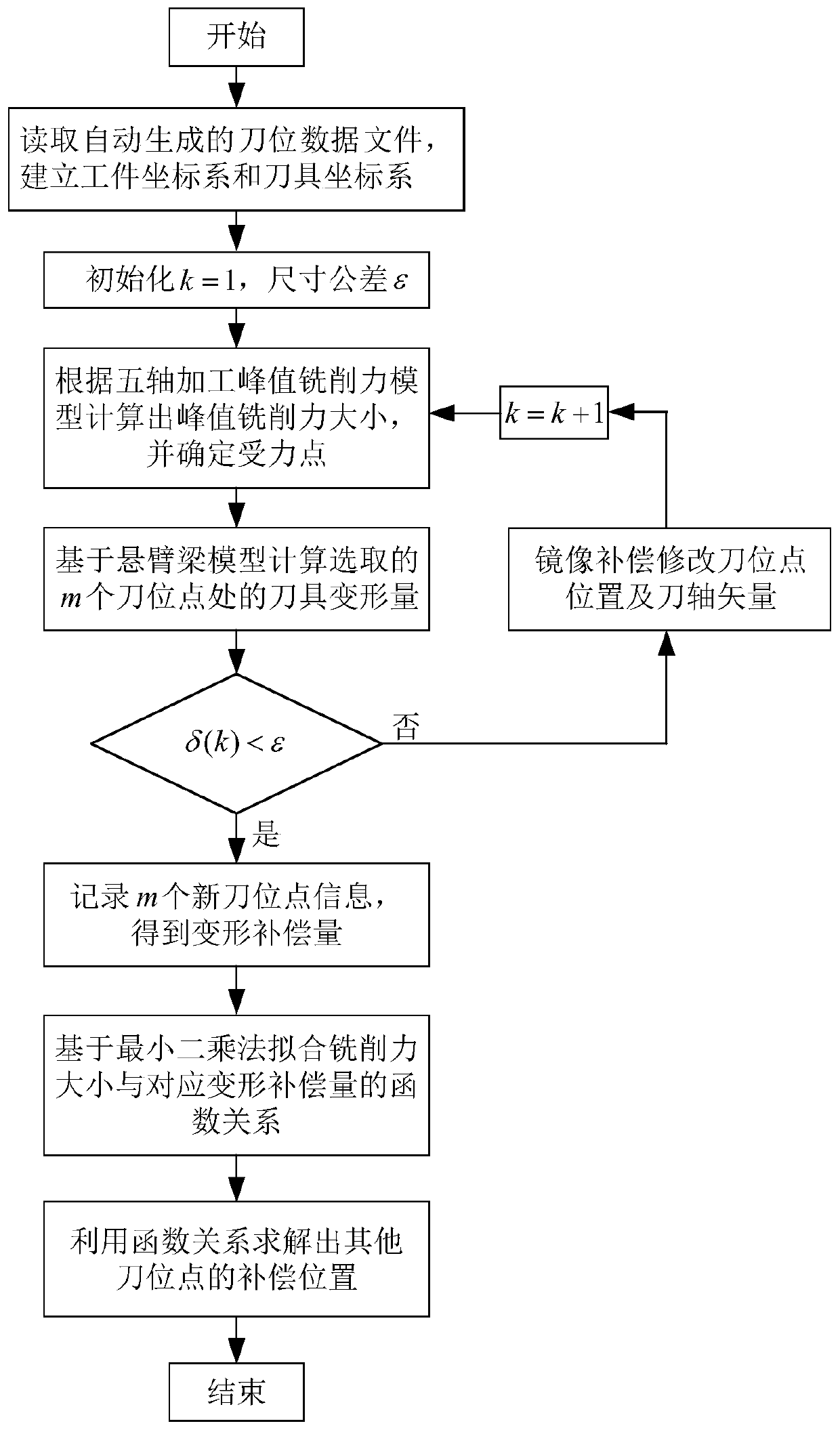

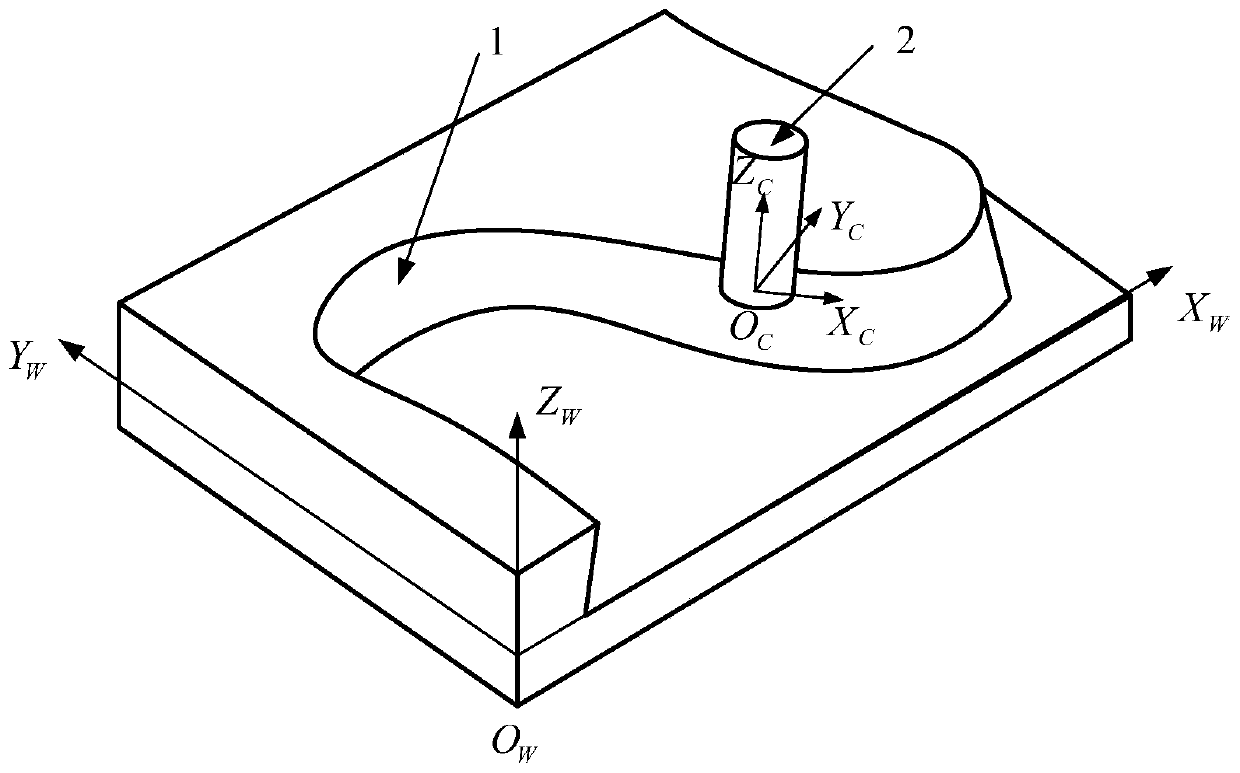

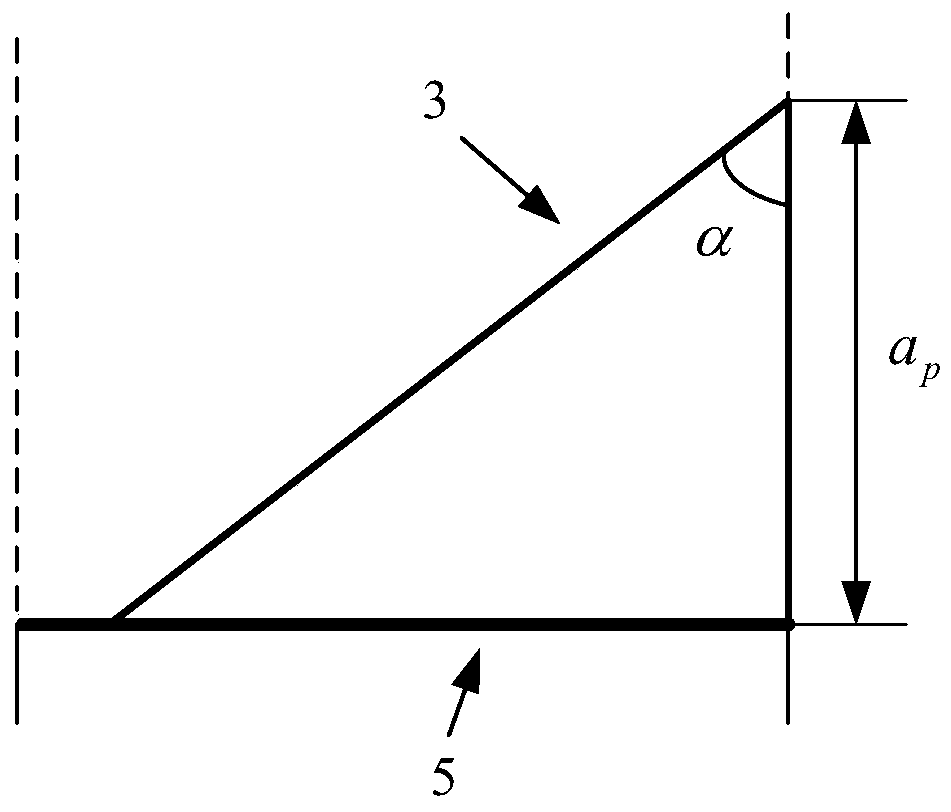

[0060] figure 1 It is the flow chart of the off-line compensation method for five-axis machining tool deformation error based on the least square method. The method first obtains the tool trajectory data file according to the three-dimensional model of the processed part and the processing parameters, establishes the workpiece coordinate system and the tool coordinate system at the tool position point, and obtains the conversion relationship between the workpiece and the tool coordinate system; secondly, according to the five-axis processing peak value The milling force model solves the peak milling force along the direction of each tool coordinate axis, and obtains the position of the corresponding stress action point according to the torque relationship; again, select m tool positions at equal intervals in the tool trajectory, and select the tool based on the cantilever beam model. The deformation of the tool under the action of the peak milling force at the point is convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com