Manufacturing device with holding tool and method for adjusting the total length of the curved edge of holding tool

A technology of manufacturing equipment, bending edges, applied in the field of manufacturing equipment, to achieve the effect of large adjustment path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] First of all, it is to be noted that in the different embodiments described, the same components have the same reference numerals / same component designations, wherein the disclosure contained throughout the specification can be similarly used with the same reference numerals / same artifact with the same component name. Furthermore, selected position indications in the description, such as at top, at bottom, at the side, relate directly to the described and depicted figures and in the event of a change in position, these position indications shall apply analogously to the new position.

[0047] In the following, the term "in particular / in particular" is to be understood as it may refer to possible more specific embodiments and more detailed descriptions of the subject matter or method steps, but does not necessarily represent a mandatory preference for the subject matter or method steps or methods. implementation.

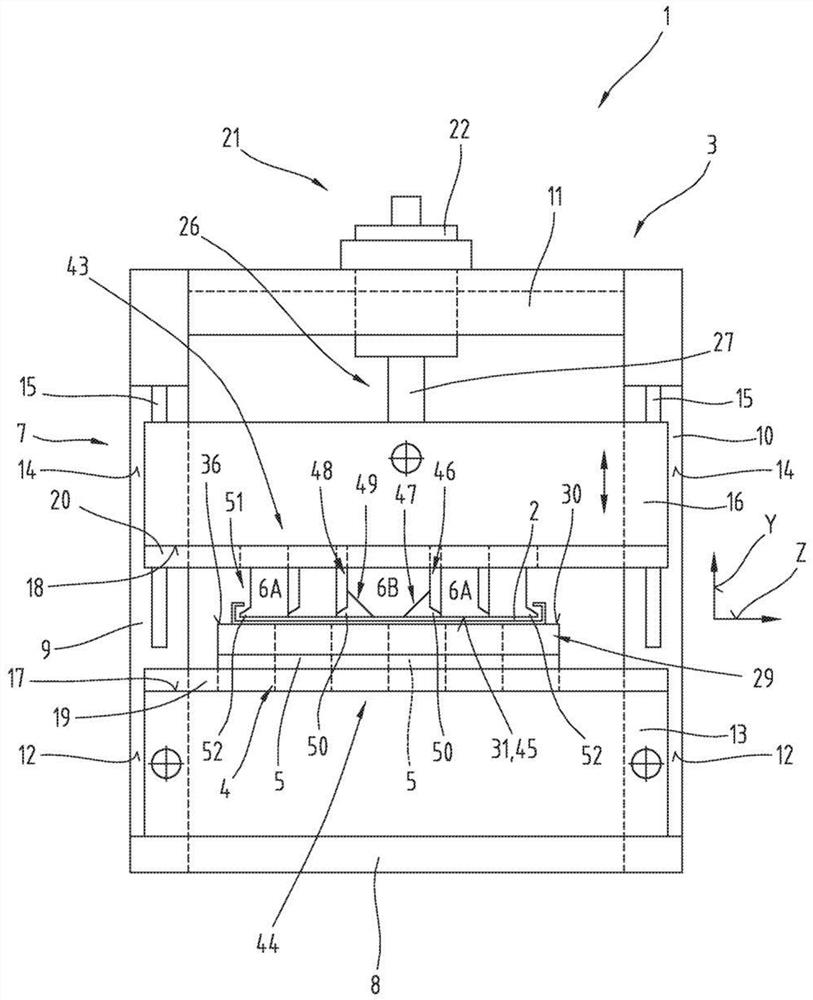

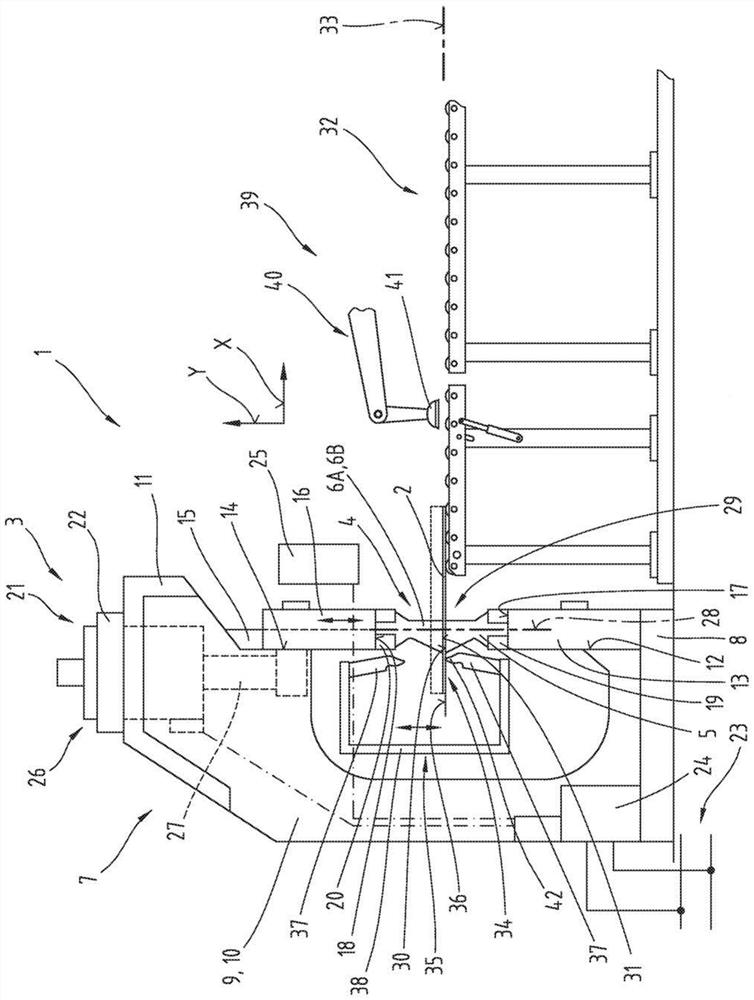

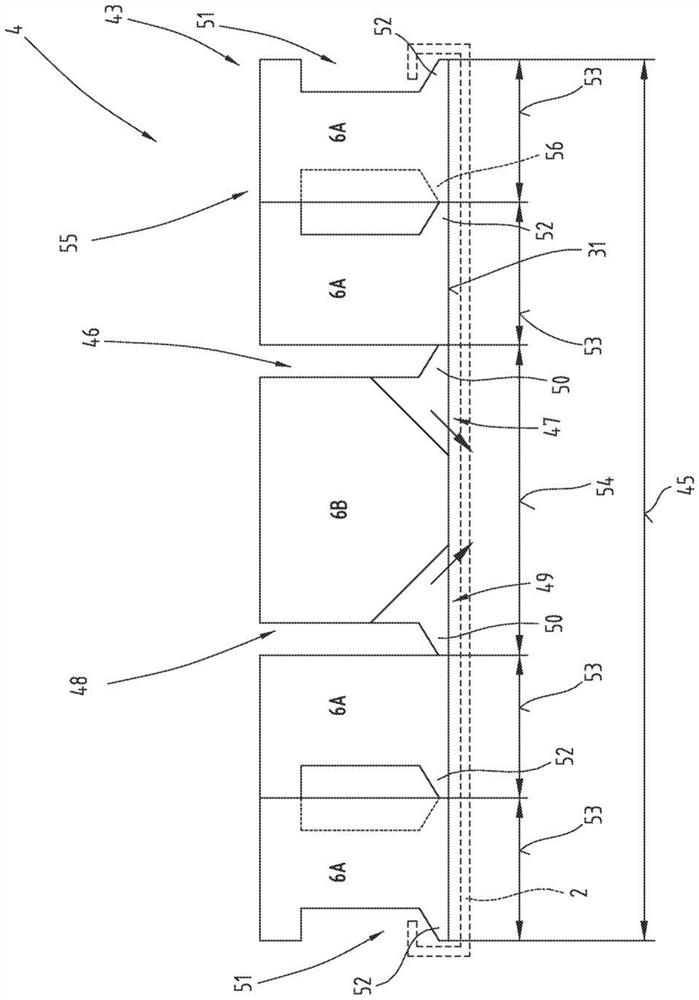

[0048] Figure 1 to Figure 5 The production plant 1 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap