TOOL DRIVING UNIT, TURNING DEVICE AND TURNING METHOD, and application thereof

A driving unit and tool technology, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of long production time, expensive, difficult to keep spheres and cylinders within tolerances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

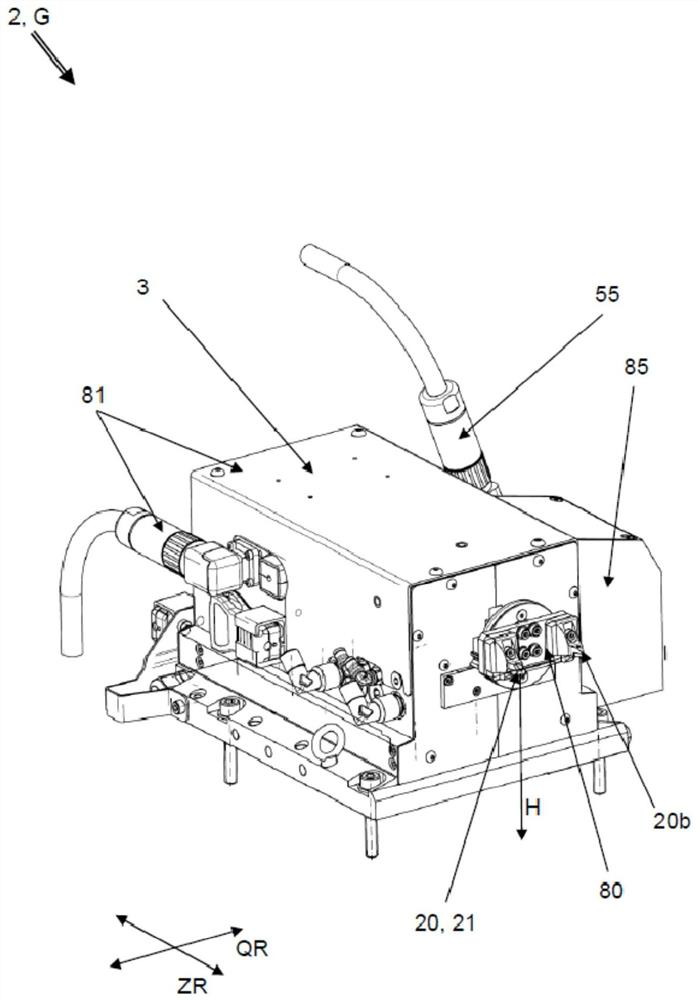

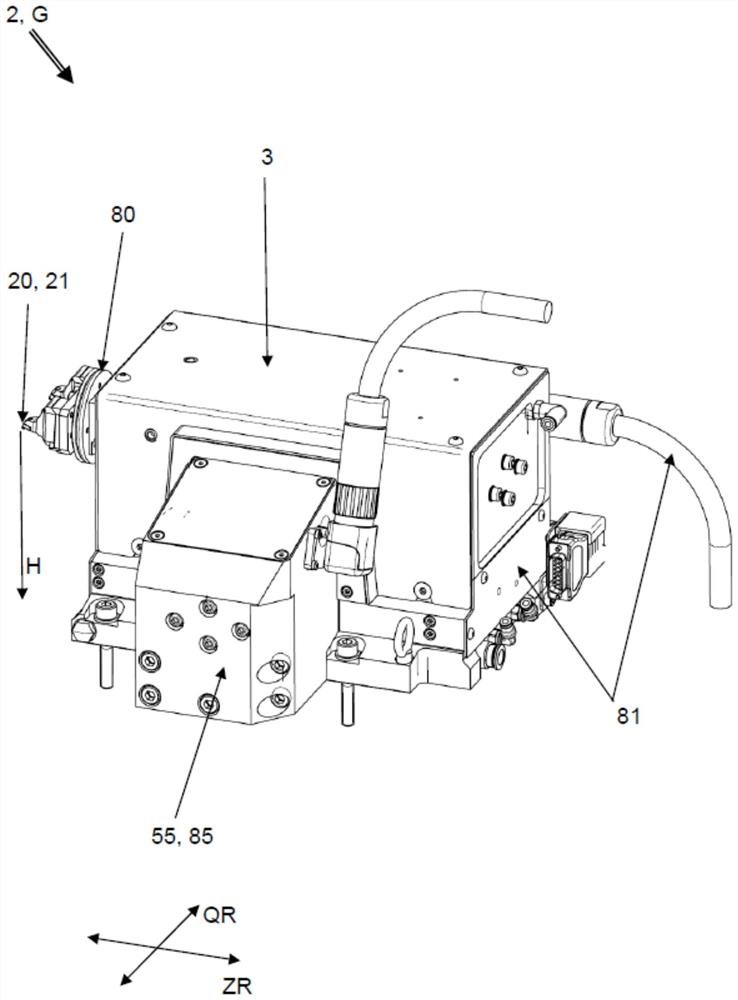

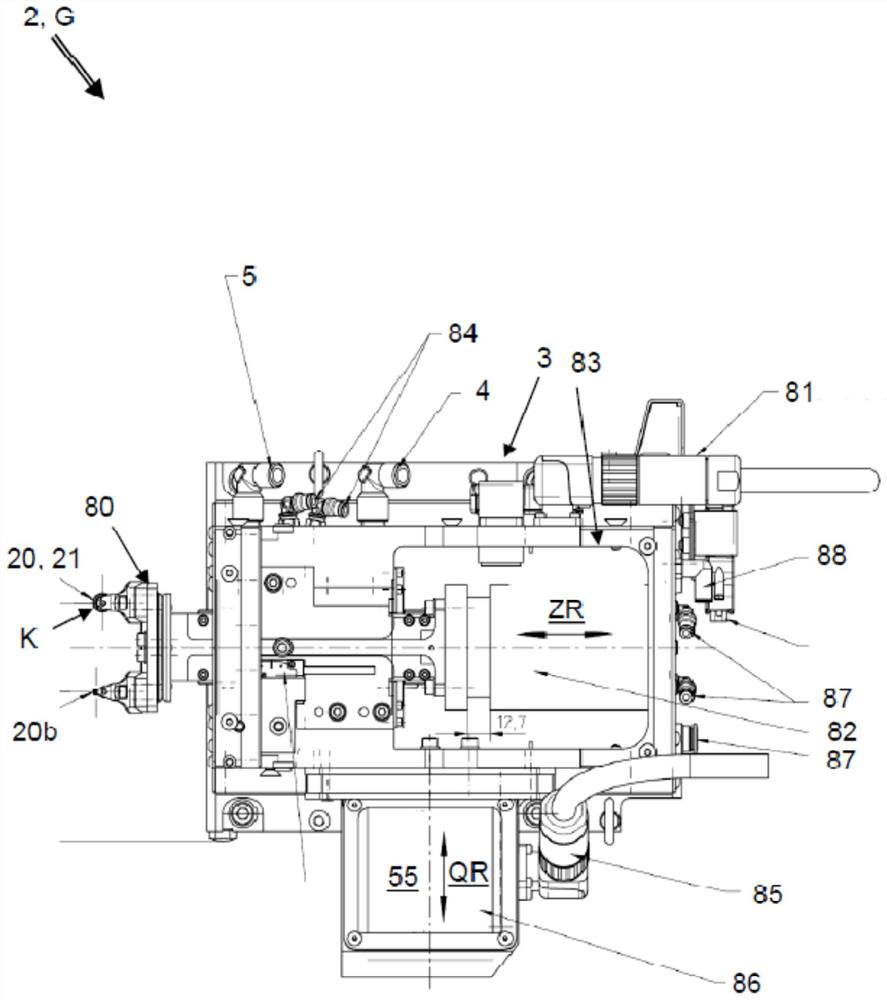

[0129] figure 1 A perspective view showing a tool drive unit 2 of a turning device for turning a workpiece (see Figure 5 ), the tool drive unit is formed as component G. exist figure 2 This component G is shown from different perspectives in . The same reference numbers therefore refer to the same components, because figure 1 and2 are described together. The components G have a common housing 3 . Protruding from one side of the housing 3 is a tool holder 80 in which the turning tool 20 with the defined cutting tool 21 is accommodated and the second turning tool 20b is accommodated additionally adjacent thereto. The cutter 21 can consist, for example, of natural diamond, synthetic diamond or ceramic, or have a CVD diamond layer (CVD=chemical vapor deposition) on a carrier substrate. The cutter 21 has a main cutting direction H in which the cutter 21 and the workpiece 100 are moved relative to each other for cutting. When using the tool drive unit 2 to process a lens bl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap