Horizontal charging bag feeding type packaging machine

A packaging machine and horizontal technology, applied in packaging and other fields, can solve problems such as vacuuming, inconvenient heat sealing, and difficult implementation of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

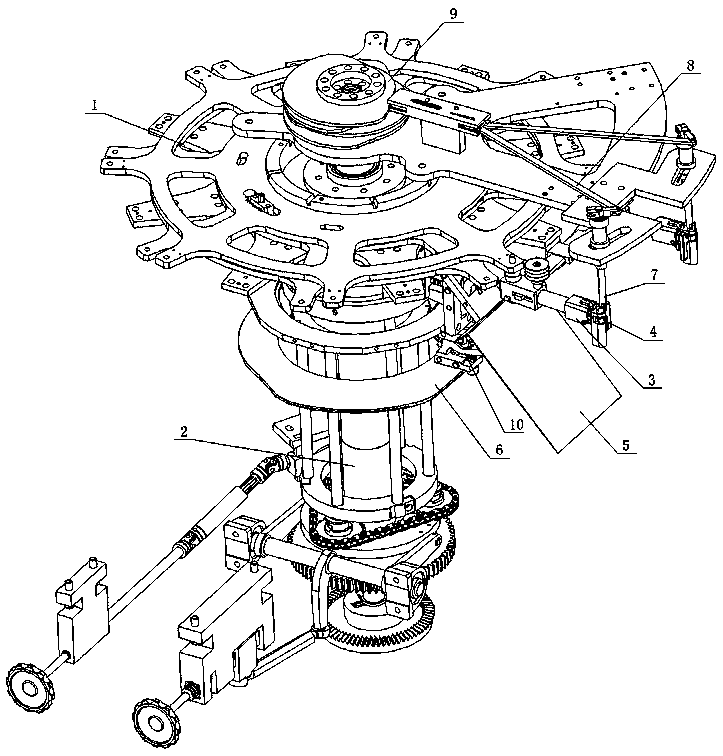

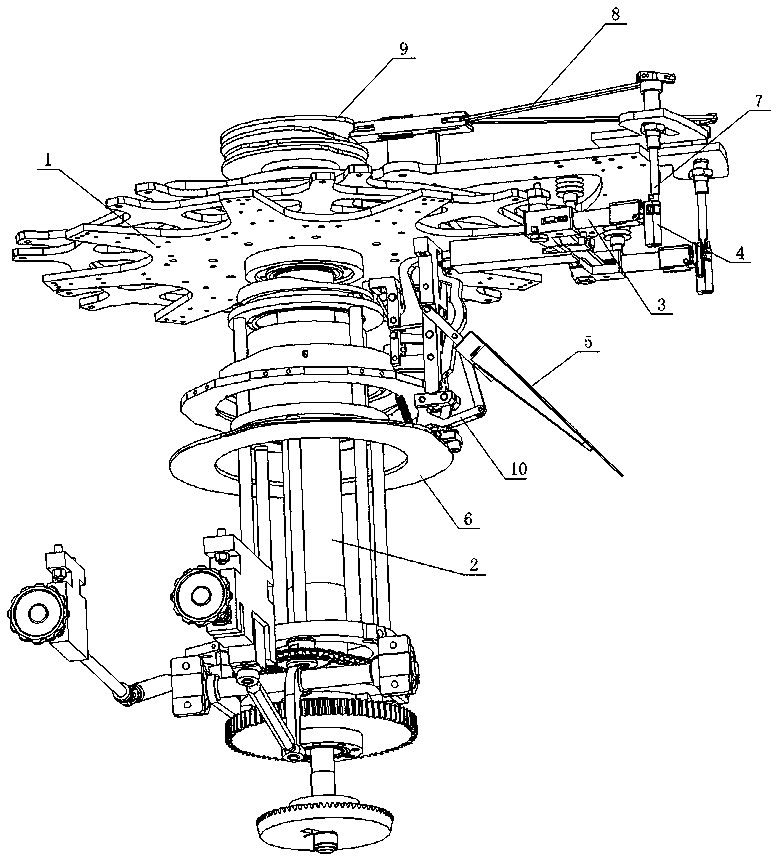

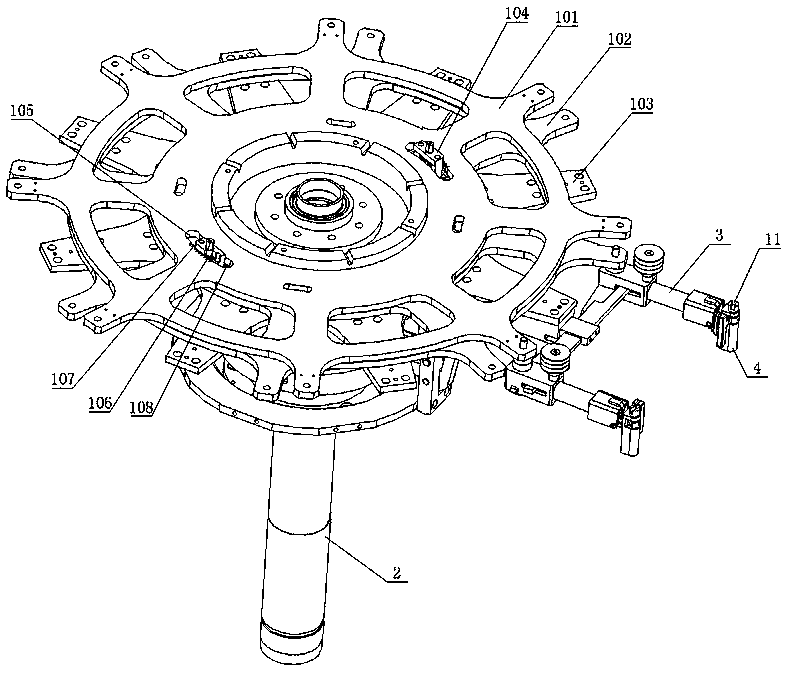

[0022] As shown in the figure, the horizontal feeding bag packaging machine of the present invention includes a turntable 1 for indexing rotation above the workbench, the turntable 1 is driven by the indexing spindle 2, and the outer circumference of the turntable 1 is provided with eight sets of clamp assemblies ( figure 1 Only one group is drawn in the middle), each group of machine clamp assemblies includes left and right machine clamp bodies 3, and the left and right machine clamp bodies 3 can swing left and right and are arranged on the turntable 1, and the turntable 1 is composed of a main disk body 103, an upper disk body 101 and The lower disc body 102 is formed, the main disc body 103 is fixedly connected to the indexing spindle 2, the upper disc body 101 and the lower disc body 102 are arranged above the main disc body 103, and the upper and lower disc bodies can be adjusted in reverse rotation relative to the main disc body 101, The specific structure is: the main d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com