A kind of gel plugging agent for oil-based drilling fluid and preparation method thereof

A technology of oil-based drilling fluid and plugging agent, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor resistance to oil invasion, and achieve adjustable gel strength, stable performance, and rheological properties. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

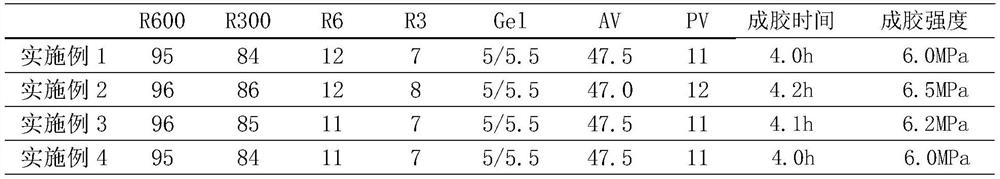

Embodiment 1

[0029] A gel plugging agent for oil-based drilling fluid comprising the following components in parts by mass: 3 parts of sodium dodecylbenzenesulfonate, 5 parts of diesel oil, 2 parts of sodium bentonite, 8 parts of N-methylolacrylamide 24 parts of acrylamide, 5 parts of oil well cement, 5 parts of barite, and 100 parts of water.

[0030] The preparation method of the gel plugging agent for oil-based drilling fluid comprises the following steps:

[0031] (1) Under stirring at a speed of 11000r / min in water, add sodium dodecylbenzenesulfonate, and continue to stir at 11000r / min for 8min;

[0032] (2) At 2500r / min, add diesel oil and stir at 11000r / min for 18min;

[0033] (3) Add sodium bentonite, N-methylolacrylamide and acrylamide at 2500r / min, and stir at 11000r / min for 22min;

[0034] (4) At 2500r / min, add oil well cement and barite, and stir at 11000r / min for 30min to obtain the product.

Embodiment 2

[0036] A gel plugging agent for oil-based drilling fluid comprising the following components in parts by mass: 5 parts of sodium cetylbenzenesulfonate, 15 parts of white oil, 4 parts of sodium bentonite, N,N-2 methylol 12 parts of acrylamide, 36 parts of acrylamide, 1 part of hydroquinone, 15 parts of oil well cement, 10 parts of ilmenite, and 100 parts of water.

[0037] The preparation method of the gel plugging agent for oil-based drilling fluid comprises the following steps:

[0038] (1) Under stirring at a speed of 13000r / min in water, add sodium cetylbenzenesulfonate, and continue to stir at 13000r / min for 12min;

[0039] (2) At 3500r / min, add white oil and stir at 13000r / min for 18min;

[0040] (3) Add sodium bentonite, N,N-2 methylol acrylamide, acrylamide and hydroquinone at 3500r / min, and stir at 13000r / min for 22min;

[0041] (4) Add oil well cement and ilmenite at a rotational speed of 3500r / min, and stir at 13000r / min for 30min to obtain the product.

Embodiment 3

[0043] A gel plugging agent for oil-based drilling fluid comprising the following components in parts by mass: 4 parts of sodium stearate, 10 parts of diesel oil, 3 parts of sodium bentonite, 10 parts of N-methylolacrylamide, acrylamide 25 parts, 0.05 parts of p-methoxyphenol, 10 parts of oil well cement, 8 parts of hematite, and 100 parts of water.

[0044] The preparation method of the gel plugging agent for oil-based drilling fluid comprises the following steps:

[0045] (1) Under stirring in water at a speed of 12000r / min, add sodium stearate, and continue stirring at 12000r / min for 10min;

[0046] (2) Under the rotating speed of 3000r / min, add diesel oil and stir for 20min at 12000r / min;

[0047] (3) Add sodium bentonite, N-methylolacrylamide, acrylamide and p-methoxyphenol at 3000r / min, and stir at 12000r / min for 20min;

[0048] (4) At 3000r / min, add oil well cement and hematite, and stir at 12000r / min for 30min to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com