Equipment for garbage classification

A garbage sorting and equipment technology, applied in garbage bins, garbage collection, applications, etc., can solve the problems of wasting garbage bin storage space, polluting the environment, increasing the labor burden of sanitation workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

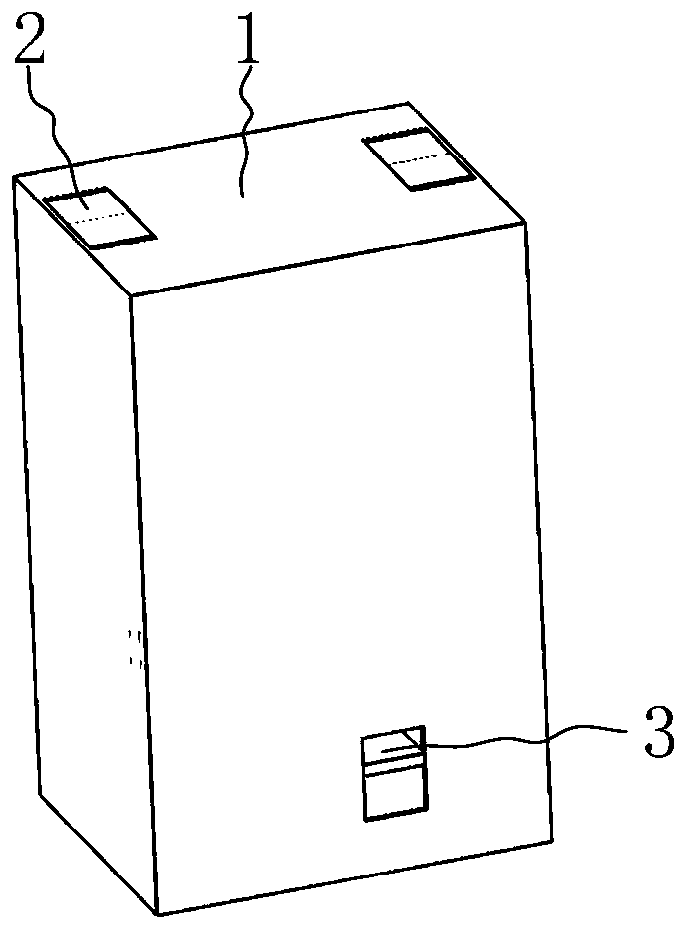

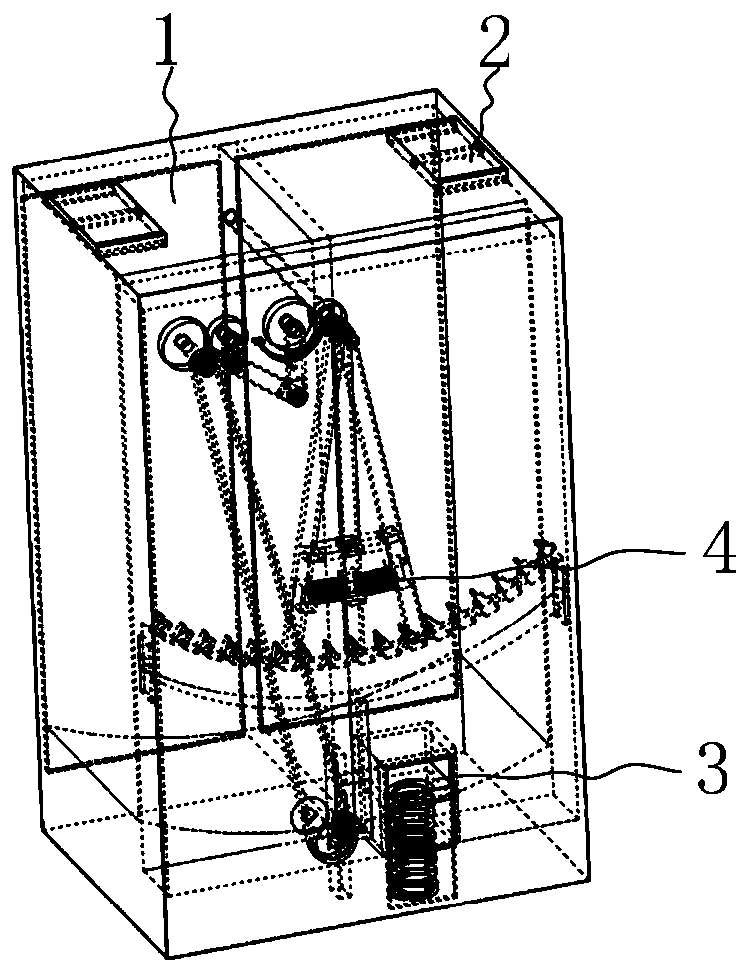

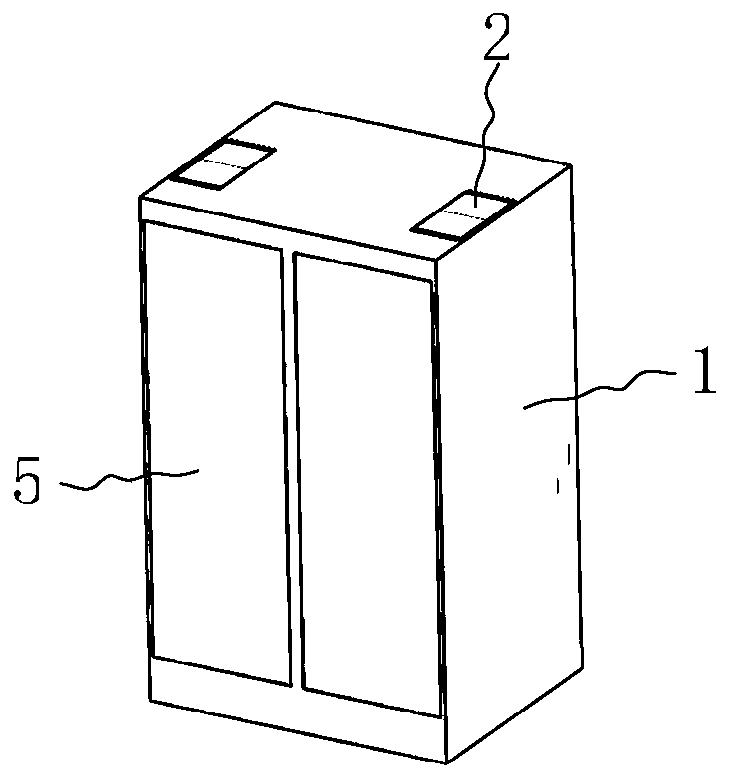

[0052] Such as figure 1 , 2 As shown, it includes a box body 1, a pedal 3, and an adjustment mechanism 4, among which Figure 8 , 9 As shown, there are two inlets 8 on the upper side of the casing 1, and a flip cover 2 is respectively installed on the two inlets 8, so that the user can put rubbish into the dustbin through the two inlets 8; Figure 8 As shown, the front side in the box body 1 has an installation cavity 10, and a square opening 47 is provided on the front wall of the installation cavity 10, and the rear side in the box body 1 has a storage cavity 48, and as Figure 4 As shown, the lower end surface of the storage chamber 48 is an arcuate surface; the func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com