The fuel cell

A fuel cell and electrolyte membrane technology, applied in fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of fuel cell power generation performance degradation, insufficient supply, etc., and achieve the effect of suppressing power generation performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

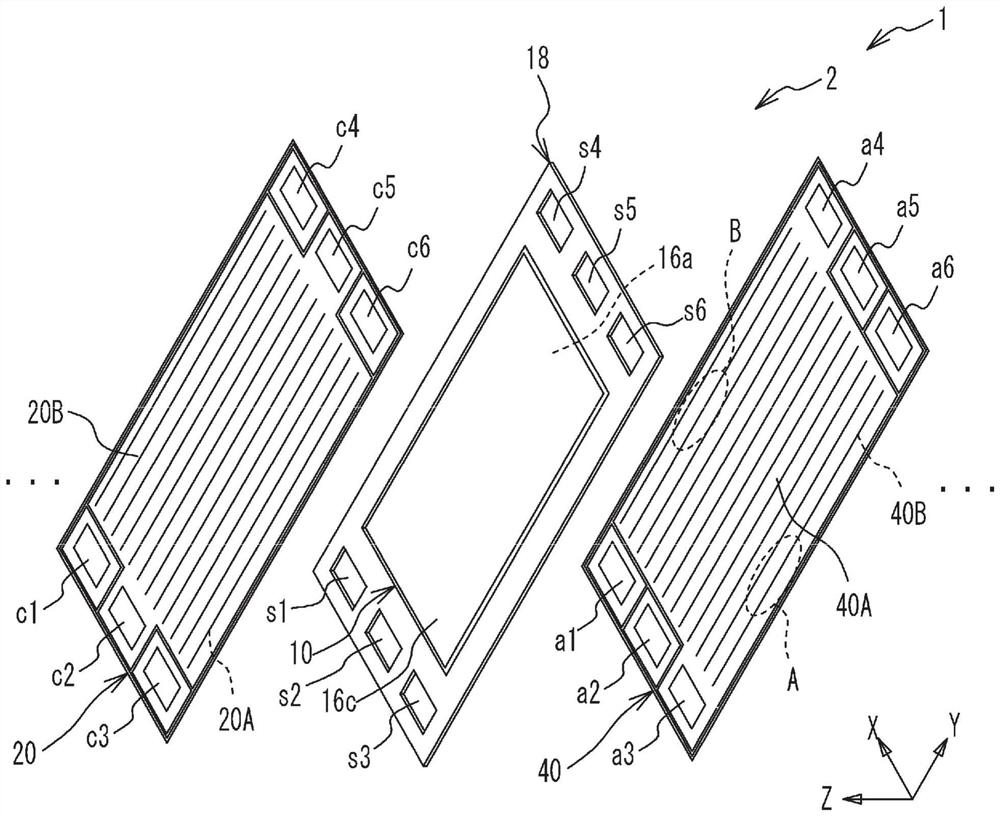

[0025] figure 1 It is an exploded perspective view of the unit cell 2 of the fuel cell 1 . The fuel cell 1 is constructed by stacking the unit cells 2 . figure 1 Only one unit cell 2 is shown and the other unit cells are omitted. unit cell 2 in figure 1 Stacked with other unit cells in the Z direction shown in . The unit cells 2 have a substantially rectangular shape. The longitudinal direction and the short direction of the unit cell 2 correspond to the figure 1 The Y and X directions shown in .

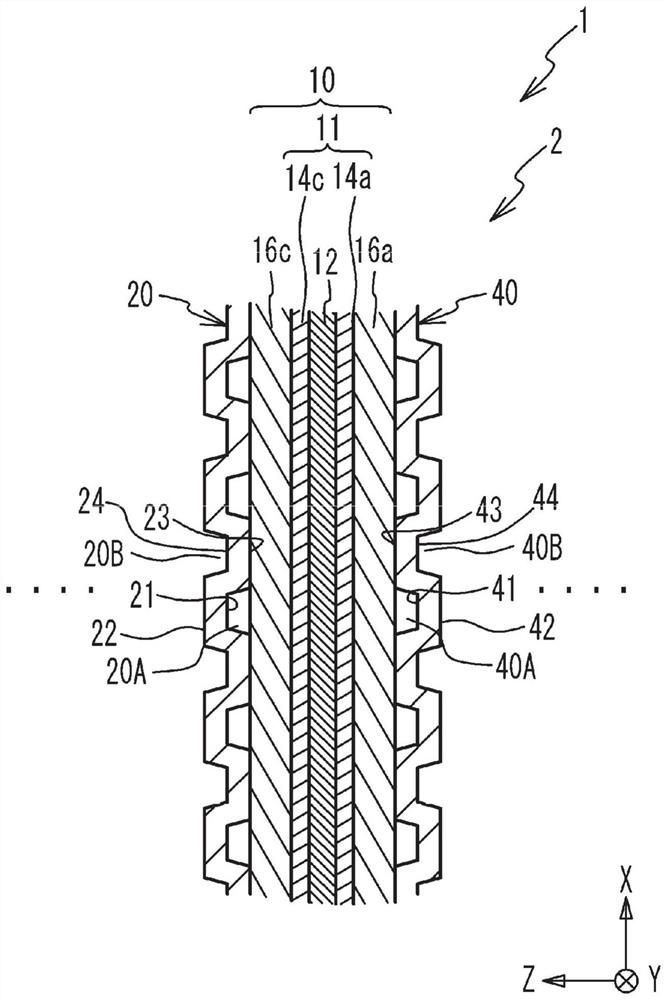

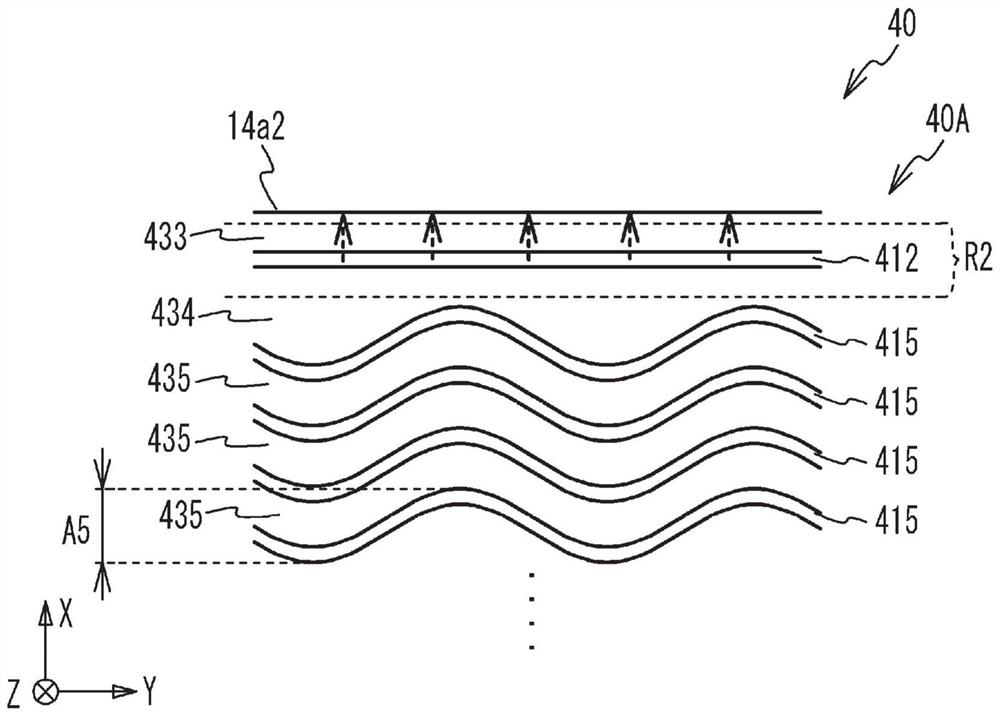

[0026] The fuel cell 1 is a solid polymer type fuel cell that generates electric power using a fuel gas (eg, hydrogen gas) and an oxidant gas (eg, oxygen gas) as reaction gases. The unit cell 2 includes: a membrane electrode gas diffusion layer assembly (MEGA) 10 ; a support frame 18 that supports the MEGA 10 ; a cathode separator 20 and an anode separator 40 (hereinafter, referred to as a separator) that connect the MEGA 10 sandwiched. The MEGA 10 has a cathode gas diffusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com