Fuel cell and manufacturing method therefor

A fuel cell and manufacturing method technology, applied in the direction of fuel cells, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as increased contact resistance, reduced power generation performance of fuel cell groups, and inability to pressurize fuel cell groups, etc., to achieve Effect of suppressing decline in power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

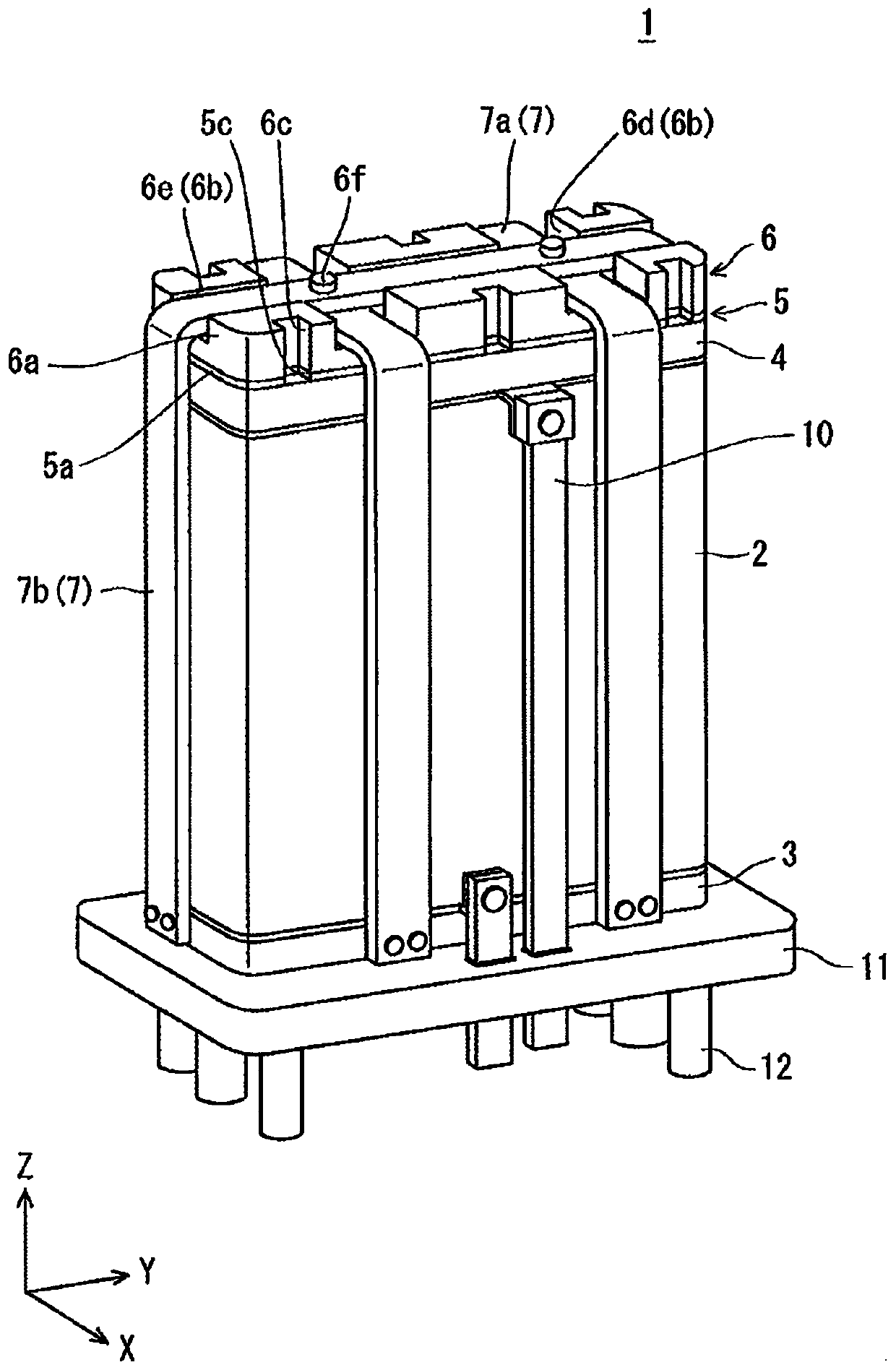

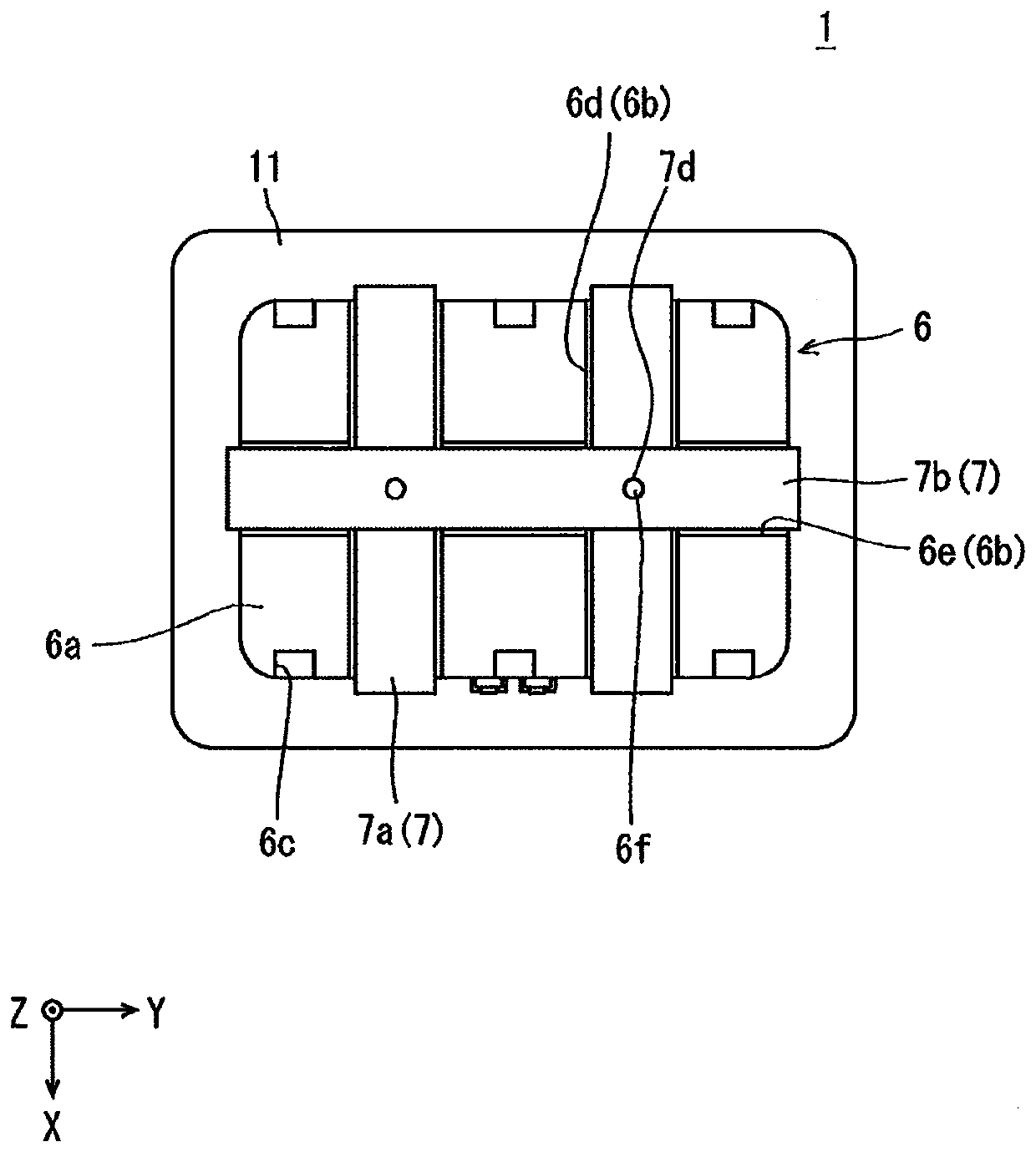

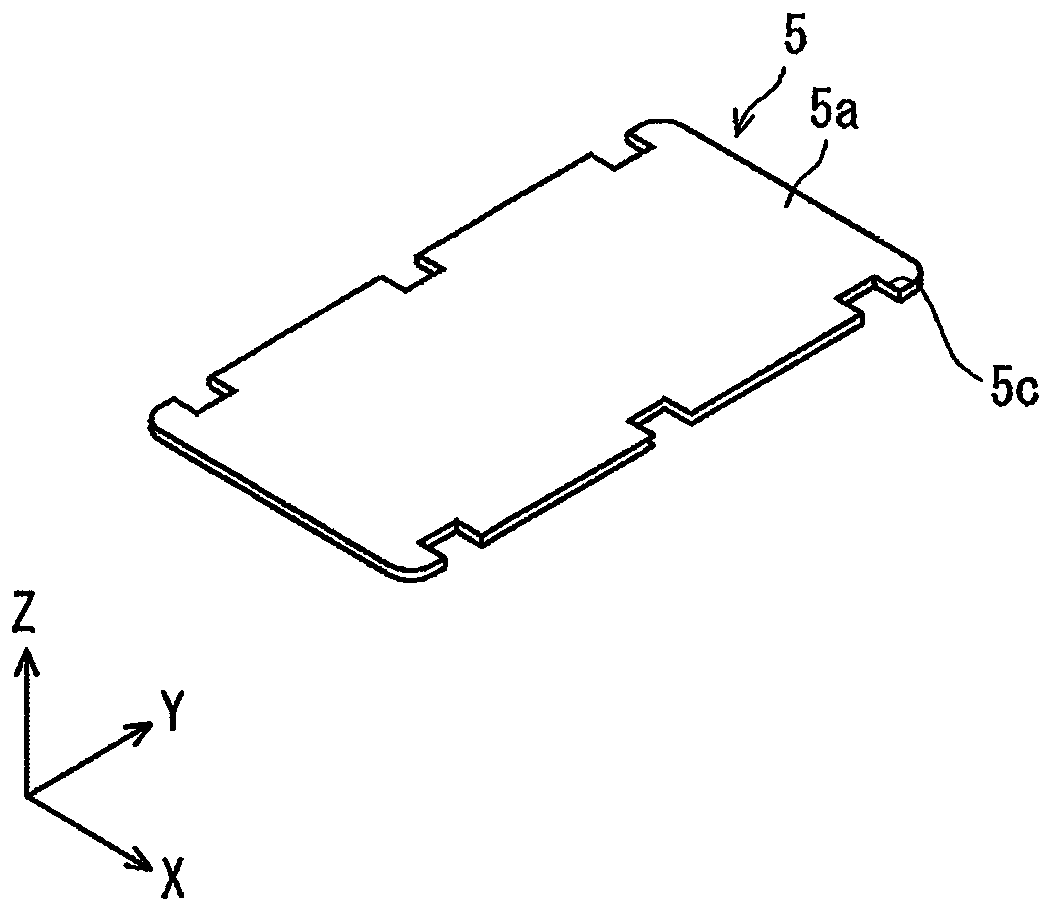

[0053] First, the structure of the fuel cell of this embodiment will be described. figure 1 It is a perspective view schematically showing the fuel cell of this embodiment. figure 2 It is a top view schematically showing the fuel cell of this embodiment. In addition, in figure 1 In , the fuel cell stack is simplified. Here, in the following description, in order to clarify the description, a three-dimensional (XYZ) coordinate system will be used for description.

[0054] like figure 1 As shown, the fuel cell 1 includes a fuel cell stack 2, a first pressurizing plate 3, a second pressurizing plate 4, an elastic sheet 5, a third pressurizing plate 6, and a constraining member 7, and is housed in an unillustrated case.

[0055] In the fuel cell stack 2, the fuel cells 100 described in the Background Art are stacked in the Z-axis direction with an insulating film interposed therebetween, and the fuel cells 100 are pressurized so as to apply a surface pressure equal to or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com