A quick access system for logistics warehousing

A fast access and logistics technology, applied to storage devices, applications, household appliances, etc., can solve the problems of manpower consumption, inconvenient handling of goods, etc., and achieve the effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

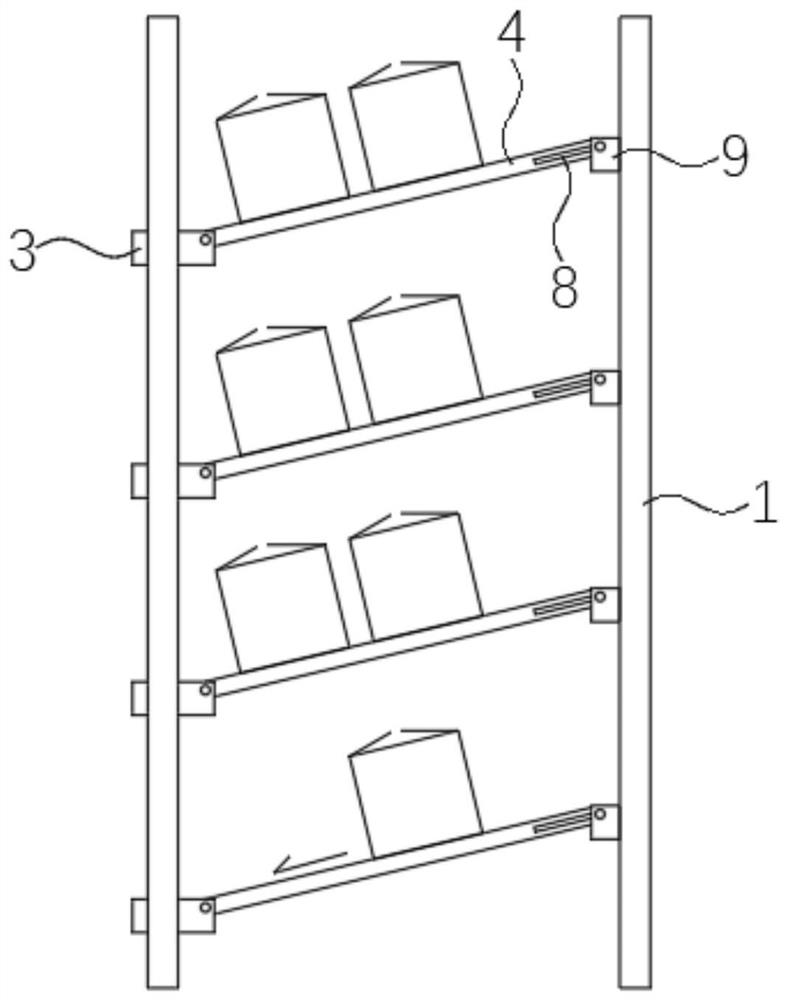

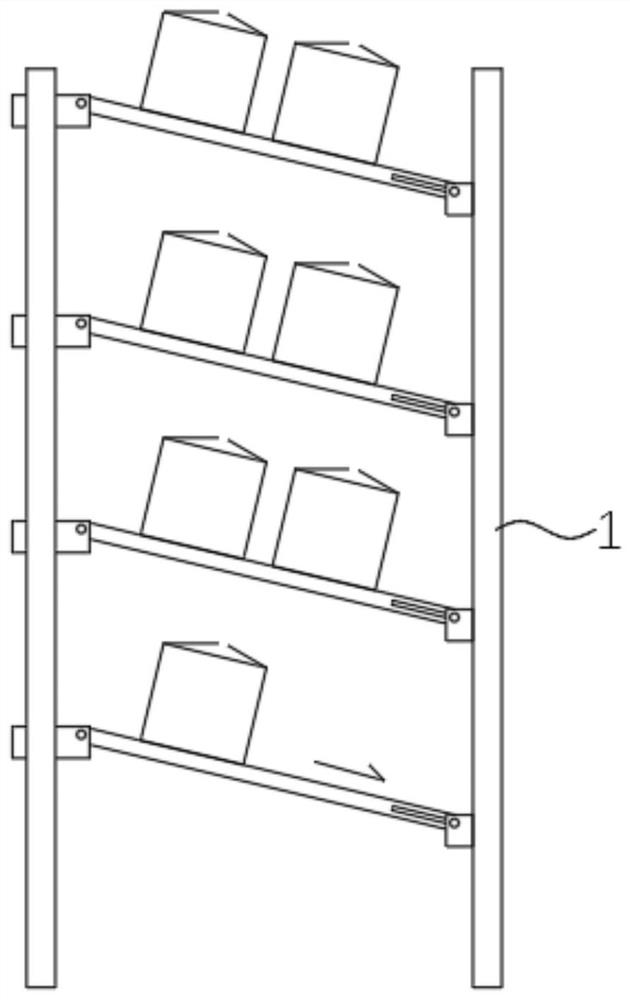

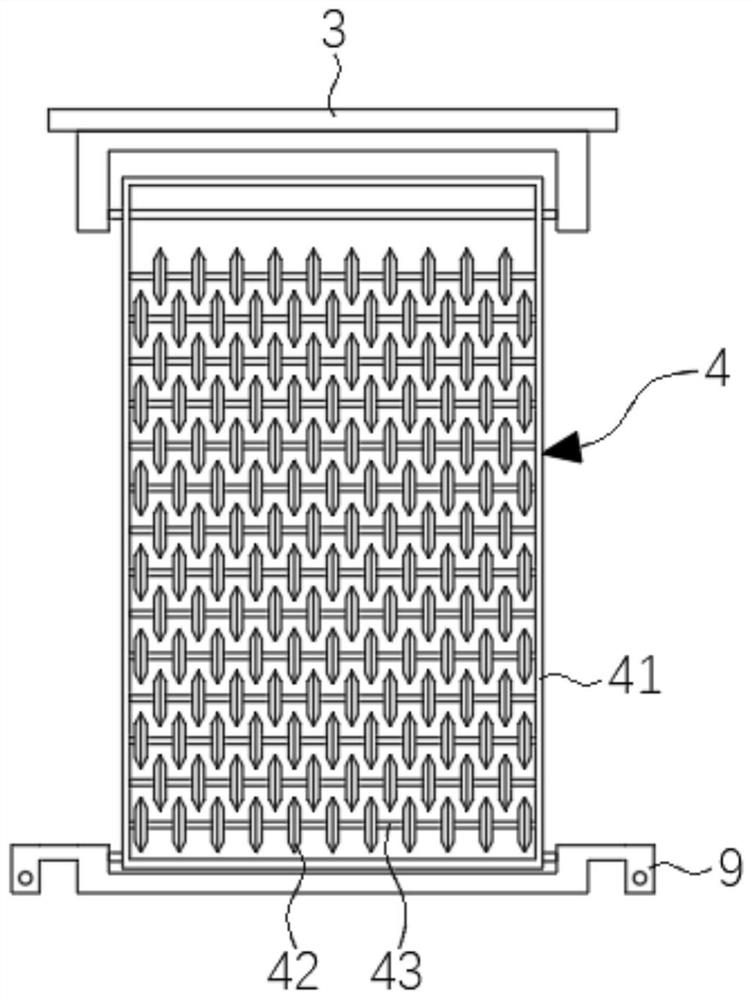

[0027] refer to Figure 1 to Figure 4 The inner side wall of the bracket 1 is fixedly connected with a plurality of first connecting plates 3 equidistantly from top to bottom, and each first connecting plate 3 is rotatably connected with a support plate 4, and the side of the support plate 4 away from the support 1 is rotatably connected with a The second connecting plate 9 is slidably connected to the support 1, and the two ends of the support 1 are equipped with a vertical lifting mechanism.

[0028] refer to Figure 4 The lifting mechanism includes a lead screw 6 and a reduction motor 7. The reduction motor 7 can use a planetary gear reduction motor, etc., or an external reducer such as a stepping motor or a servo motor. The two sides of the support 1 are symmetrically provided with vertical slides. Slot 2, leading screw 6 is vertically arranged in the chute 2, the leading screw 6 on both sides rotates synchronously through the transmission mechanism, the bottom end of the...

Embodiment 2

[0039] refer to Figure 5 with Image 6 , The difference between Embodiment 2 and Embodiment 1 lies in the difference of the lifting mechanism. In this embodiment, each supporting plate 4 is provided with a separate lifting mechanism, so as to control the independent movement of each layer of supporting plates, and the use is more flexible.

[0040] The elevating mechanism includes a weight block 11, an overturning frame 12, a fixed frame 13, a cylinder 14 and a cross bar 16, and the specific connection methods are as follows:

[0041] The overturning frame 12 is rotatably connected to the fixed frame 13, one side of the overturning frame 12 is fixedly connected with a cross bar 16, the other side of the overturning frame 12 is fixedly connected with a weight block 11, and one end of the overturning frame 12 is connected with a lever for driving its lever movement. Cylinder 14.

[0042] Both ends of the support plate 4 are fixedly connected with a hook-shaped spacer 15 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com