Staggering type perforating machine

A technology of punching machine and case, which is applied to paper/cardboard containers, containers, bag making operations, etc., and can solve the problems of asymmetrical dislocation through-holes and inability to punch out dislocation-type through-holes in packaging bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

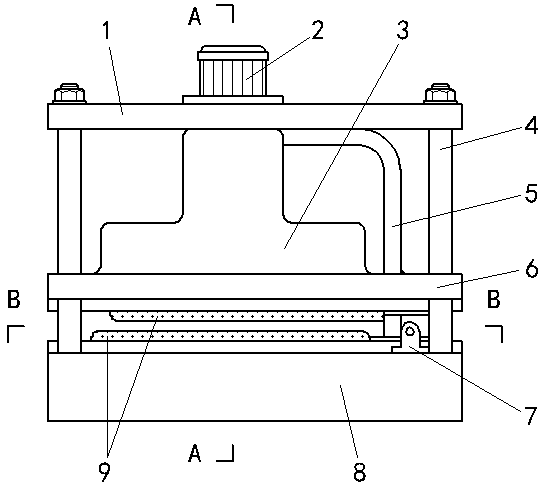

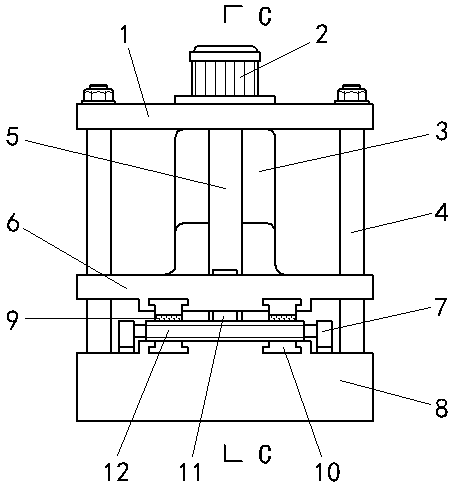

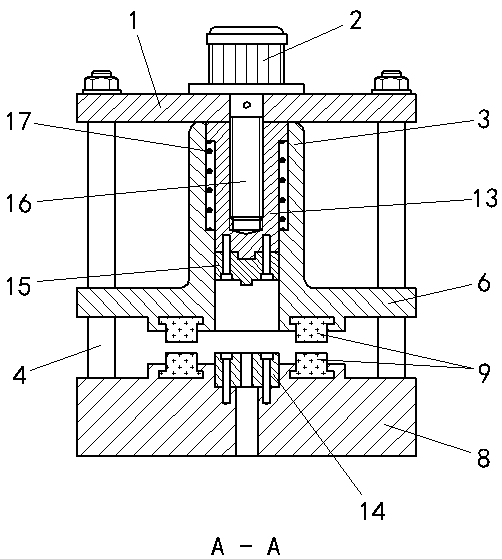

[0022] exist figure 1 , figure 2 , image 3 , Image 6 , Figure 7 , Figure 10 Among them, the top plate 1 and the bottom plate 8 are both rectangular plate structures and arranged parallel to each other up and down, and the four corners of the top plate 1 and the bottom plate 8 are connected by four columns 4 respectively. The motor 2 is connected on the top plate 1 , and the rotating shaft of the motor 2 is set as a screw shaft 16 . The die 14 is connected on the bottom plate 8, and the die 14 is a rectangular plate structure provided with several longitudinal punching holes on the transverse central axis. Front and rear slide grooves 18 parallel to the transverse central axis of the die 14 are provided on the bottom plate 8 along the front and rear sides of the die 14 , and the slide grooves 18 are dovetail groove structures. Front and rear washboards 9 are respectively arranged in the front and rear chute 18 , the upper end surface of the washboard 9 is flush with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com