Chain link connecting assembly and wearable equipment

A technology for connecting components and wearable devices, applied to bracelets, watch straps, clothing, etc., can solve the problems of lack of limited wearing, complex manufacturing process of watch straps, poor user experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

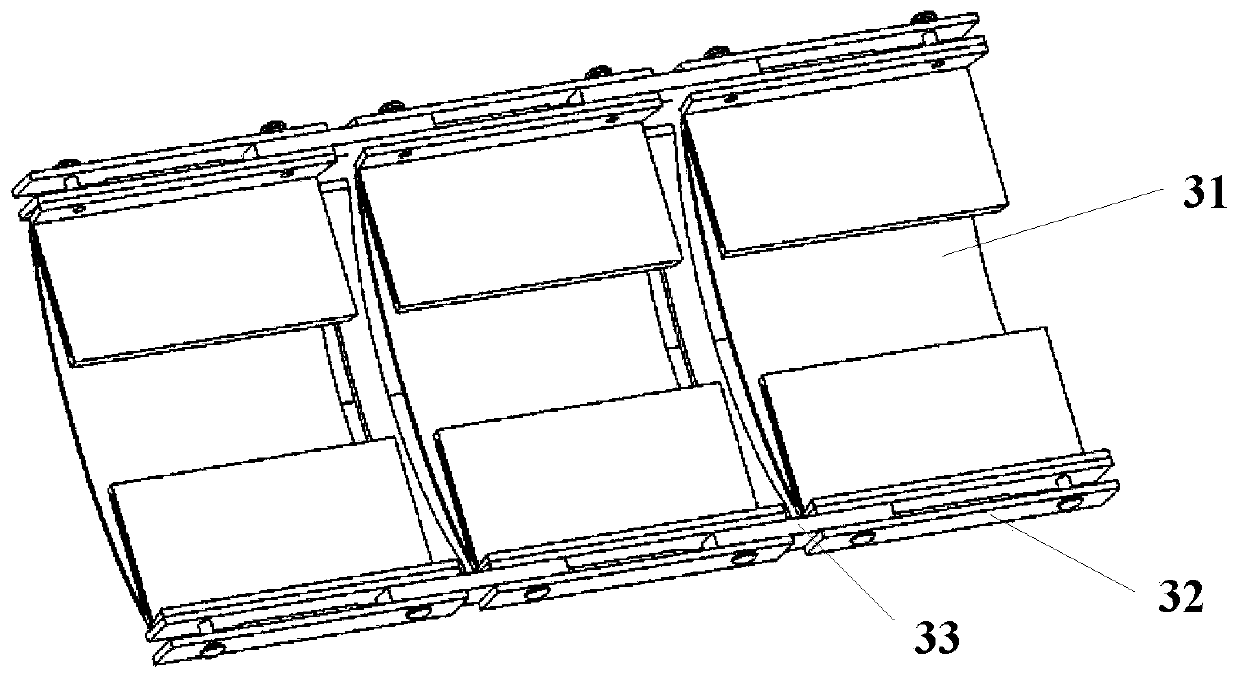

[0065] This embodiment provides a link connection assembly, which is used for wearable links of wearable devices, such as Figure 3-9 As shown, the chain link connecting assembly 30 includes at least two chain links 31, a I-shaped block 32 adjacent to the chain link 31, and a connecting piece 33 arranged between two adjacent I-shaped blocks 32, specifically , the I-shaped block 32 is connected with each chain link 31, and the I-shaped block 32 is located on the outside of the chain link 31, the I-shaped block 32 and the connecting piece 33 are connected by pins, and every two I-shaped pieces 32 are connected by a connecting piece 33 links to each other, then the I-shaped block 32 is also arranged between every two chain links 31; The connecting piece 33 and the pin connect at least two chain links 31 ; and there is an overlapping area between the connecting piece 33 and the I-shaped block 32 to ensure the stability of the chain link connecting assembly.

[0066] The I-shaped ...

no. 2 example

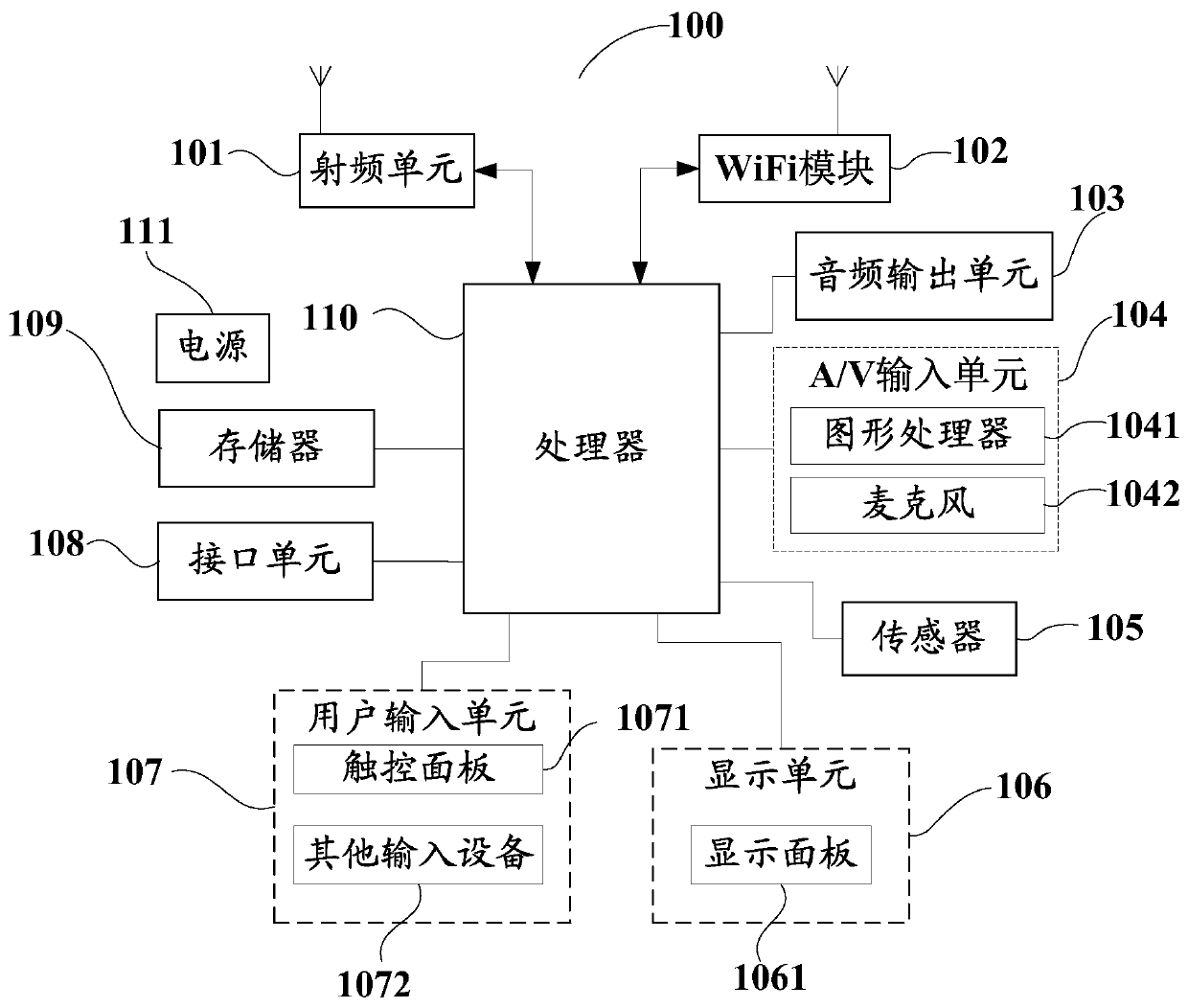

[0079] This embodiment provides a wearable device, such as Figure 11 , 12 As shown, it includes at least a display screen 1101, and a link connection assembly 30 located under the display screen 1101 as in the above-mentioned embodiments. The display screen 1101 is fixedly connected to the link connection assembly 30, and the wearable Wearing of the device; the display screen 1101 may include a flexible screen, and the flexible screen is set in such a way that the flexible screen is also bent correspondingly when the device is worn. like Figure 12 as shown, Figure 12 An exploded view of the wearable device provided for this embodiment.

[0080] The chain link connecting assembly 30 includes at least two chain links 31, the I-shaped block 32 connected adjacent to the chain link 31, the connecting piece 33 arranged between two adjacent I-shaped blocks 32, and the I-shaped block 32 , the connecting piece 33 and the pin connect at least two chain links 31 , wherein the pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com