A double-layer composite casing with mismatched strength

A combined casing and casing technology, applied in casing, drill pipe, drill pipe, etc., can solve the problems of inability to carry out oil production projects, lack of research results of material strength matching, and complicated construction, so as to reduce the risk of plastic deformation failure , reduce the risk of plastic deformation failure, improve the effect of anti-extrusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

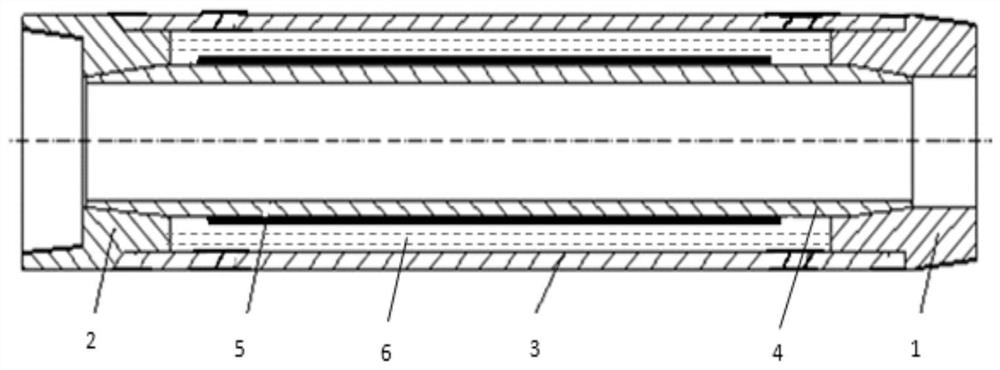

[0020] Such as figure 1 As shown in the structure, the external threaded joint 1 and the internal threaded joint 2 are casing collars with an outer diameter of 153.7mm, the outer casing 3 adopts a 139.7*6.20mm N80 casing, and the inner layer casing 4 adopts a 114.3*6.35mm P110 casing,

[0021] The material strength of the outer casing 3 is 80ksi, the material strength of the inner casing 4 is 110ksi, and the material strength of the outer casing 3 is 72.7% of the material strength of the inner casing 4; 139.7*6.20mm N80 outer layer The material elongation of the sleeve 3 is 22%.

[0022] The outer casing 3 has a wall thickness of 6.20mm and an inner diameter of 127.3mm; the inner casing has an outer diameter of 114.3mm and a wall thickness of 6.35mm.

[0023] The surface of the inner casing has a layer of Cr coating with a thickness of 30-50μm, and the hardness of the coating is HRC58.

[0024] The annular gap between the outer casing 3 and the inner casing 4 is 6.5mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com