Plastic uptake processing equipment

A processing equipment and plastic technology, which is applied in the field of plastic blister processing equipment, can solve the problems of poor adsorption capacity of adsorption holes, molded plastics that cannot reach the shape, and plastics that are not easy to shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

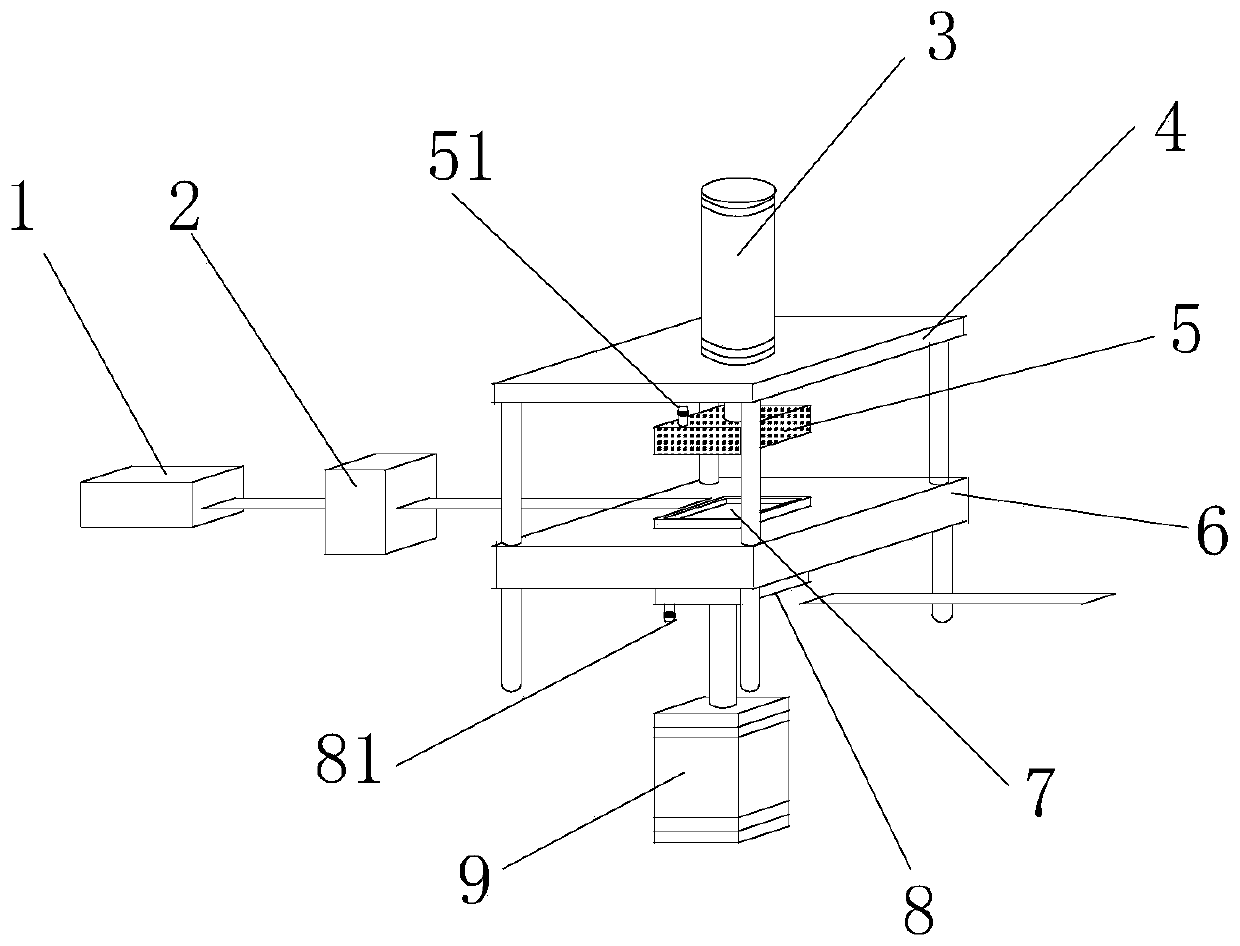

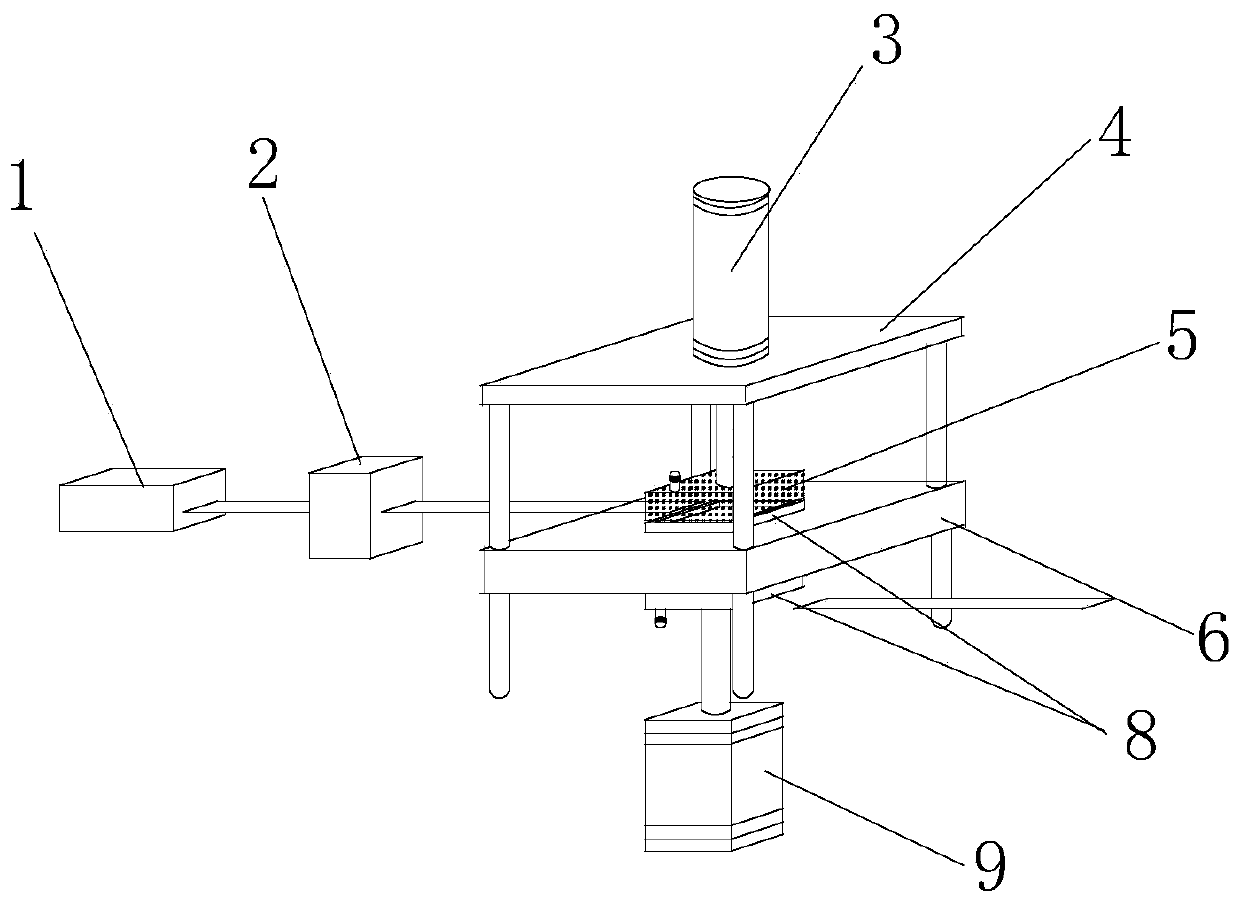

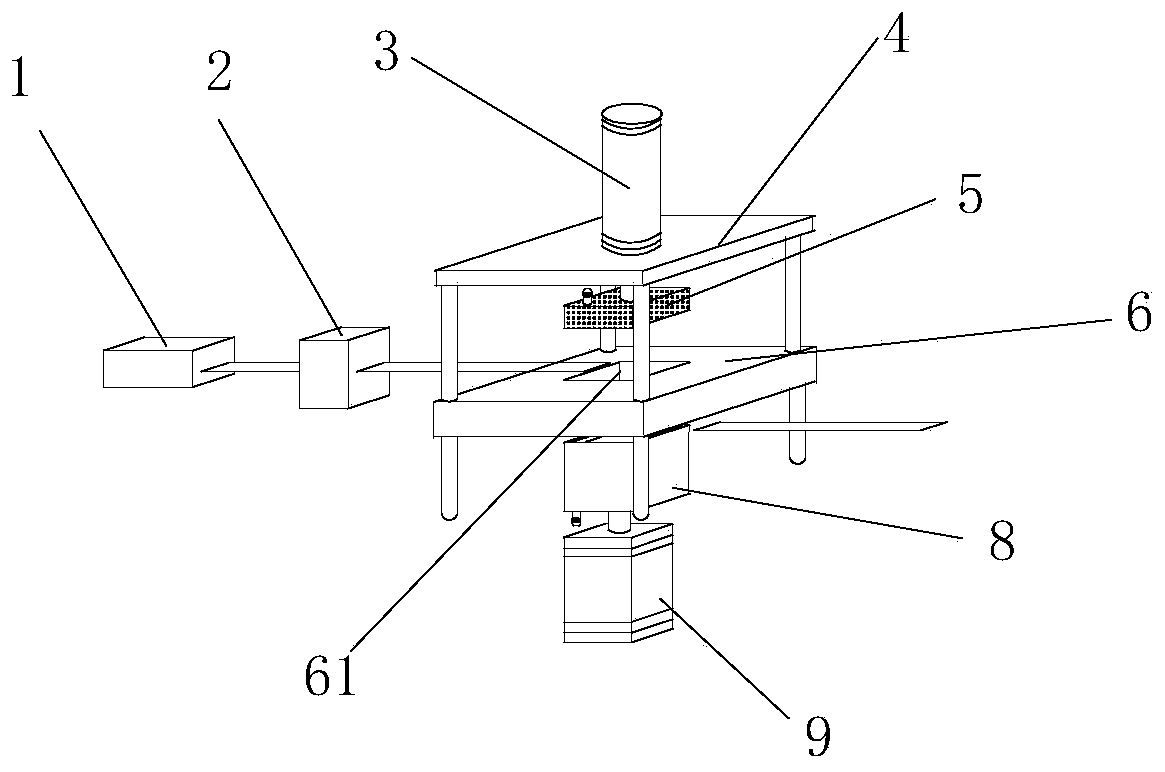

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0024] A plastic blister processing equipment of the present invention includes a plastic extrusion mechanism 1, a plastic cutting mechanism 2, a plastic suction mold assembly and a heating assembly 5, and the plastic extrusion mechanism 1 extrudes the plastic into a sheet and then passes through the conveying belt Transported to the plastic cutting mechanism 2 for stereotyped cutting, the heating assembly 5 is arranged under the upper fixing frame 4, and the upper fixing frame 4 is provided with a first driving cylinder 3 for driving the heating assembly 5 to move up and down, so The plastic-absorbing mold assembly is directly below the heating assembly 5, the upper fixing frame 4 is fixed on the lower fixing frame 6, and the center position of the lower fixing frame 6 is provided with a hole 61 through which the plastic-absorbing mold assembly passes. A second drive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap