Retractor core shaft assembly and safety belt retractor

A retractor and mandrel technology, which is applied in the field of safety belts, can solve problems such as the unsatisfactory force-limiting capacity of the retractor mandrel assembly, and achieve the effects of improving force-limiting capacity, increasing frictional resistance, and extending force-limiting travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

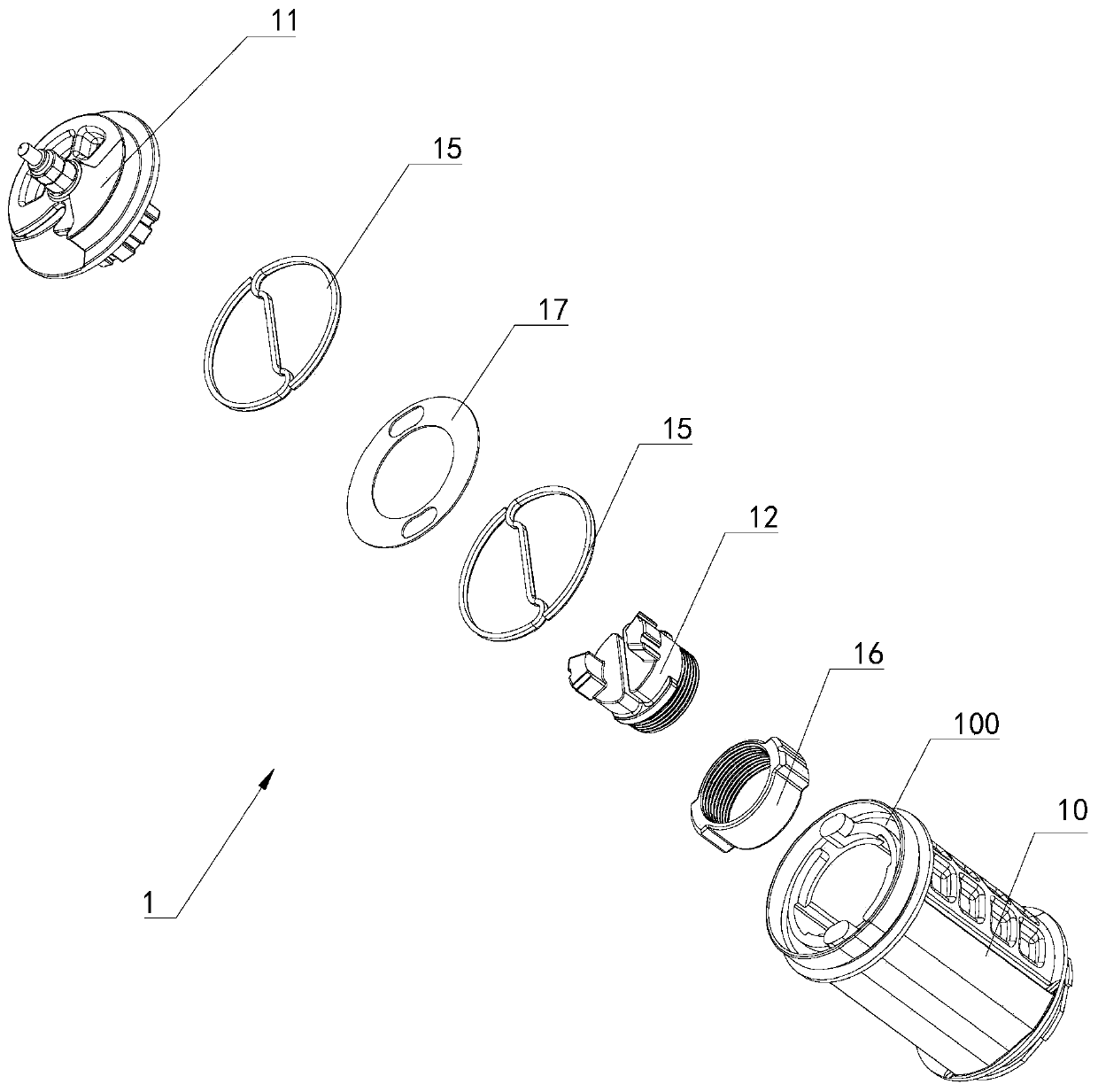

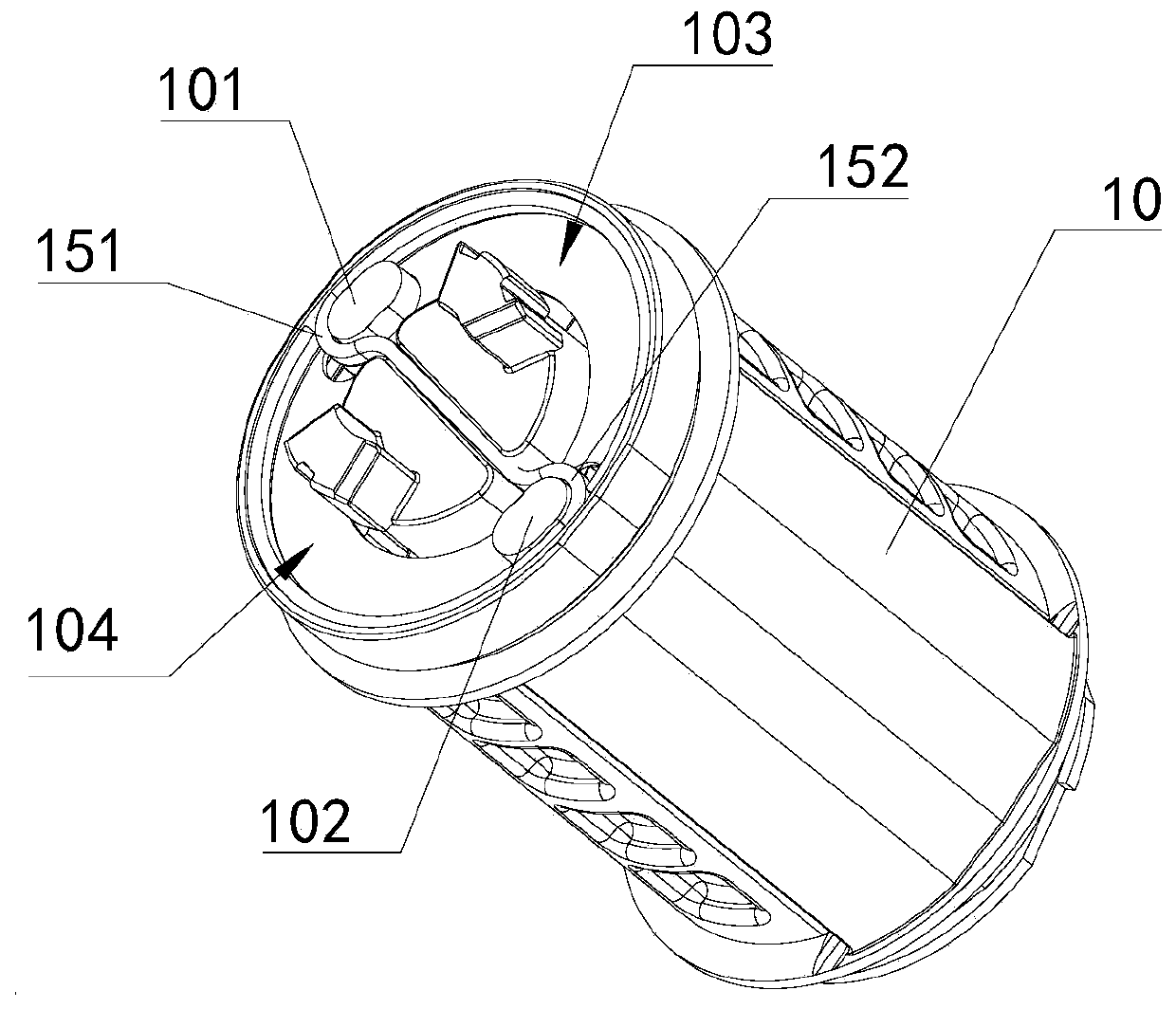

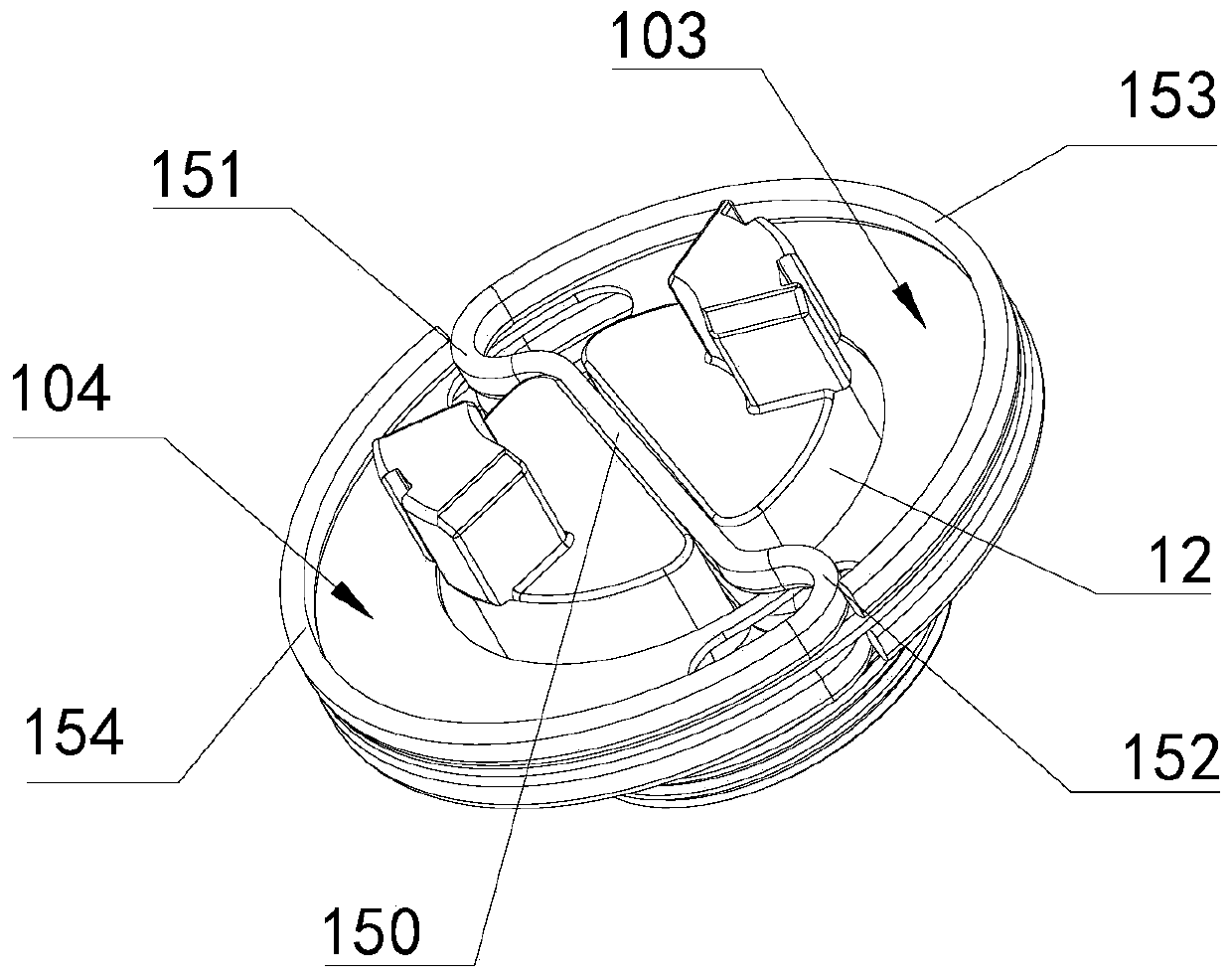

[0044] see Figure 1 to Figure 8 As shown, this embodiment provides a retractor mandrel assembly; figure 1 An exploded view of the retractor mandrel assembly provided for this embodiment, in which the structure of the retractor mandrel assembly is simply shown; figure 2 A schematic structural view of the first embodiment of the retractor mandrel assembly provided in this embodiment; image 3 for figure 2 A partial schematic view of the retractor mandrel assembly in , clearly showing the figure 2 The relative positional relationship between the multiple force limiting rings and the torque head; Figure 4 A schematic structural view of the second embodiment of the retractor mandrel assembly provided in this embodiment; Figure 5 for Figure 4 A partial schematic view of the retractor mandrel assembly in , clearly showing the Figure 4 The relative positional relationship between the multiple force limiting rings and the torque head; Image 6 A schematic structural view...

Embodiment approach

[0066] In the alternative scheme of this embodiment, see figure 2 with image 3 As shown, the second end surface 120 is provided with an installation groove 121 , and the fixing portions 150 of the plurality of force limiting rings 15 are all fitted in the installation groove 121 . This is the first implementation of the retractor mandrel assembly 1. Specifically, when the first push block 101 abuts against the first push portion 151 and the second push block 102 abuts against the second push portion 152, the Under the combined action of the installation groove 121 and the first push block 101, the two ends of the first push portion 151 are out of sync, so that as the mandrel 10 starts to rotate, the first push block 101 will directly push the first extension portion 153 Winding on the outer circumference of the torque head 12, similarly, under the joint action of the installation groove 121 and the second pushing part 152, the two ends of the second pushing part 152 are asy...

Embodiment 2

[0092]Embodiment 2 provides a seat belt retractor, which includes the retractor spindle assembly in Embodiment 1, and the technical features of the retractor spindle assembly disclosed in Embodiment 1 are also applicable to this embodiment , Embodiment 1 The technical features of the disclosed retractor mandrel assembly will not be described repeatedly.

[0093] see Figure 9 combine Figure 1 to Figure 8 As shown, the seat belt retractor 2 provided in this embodiment includes the retractor spindle assembly 1 provided in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com