Isometric pile driver with adjustable transmission ratio

A technology of transmission ratio and pile driver, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., and can solve the problem that the pile driver cannot move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

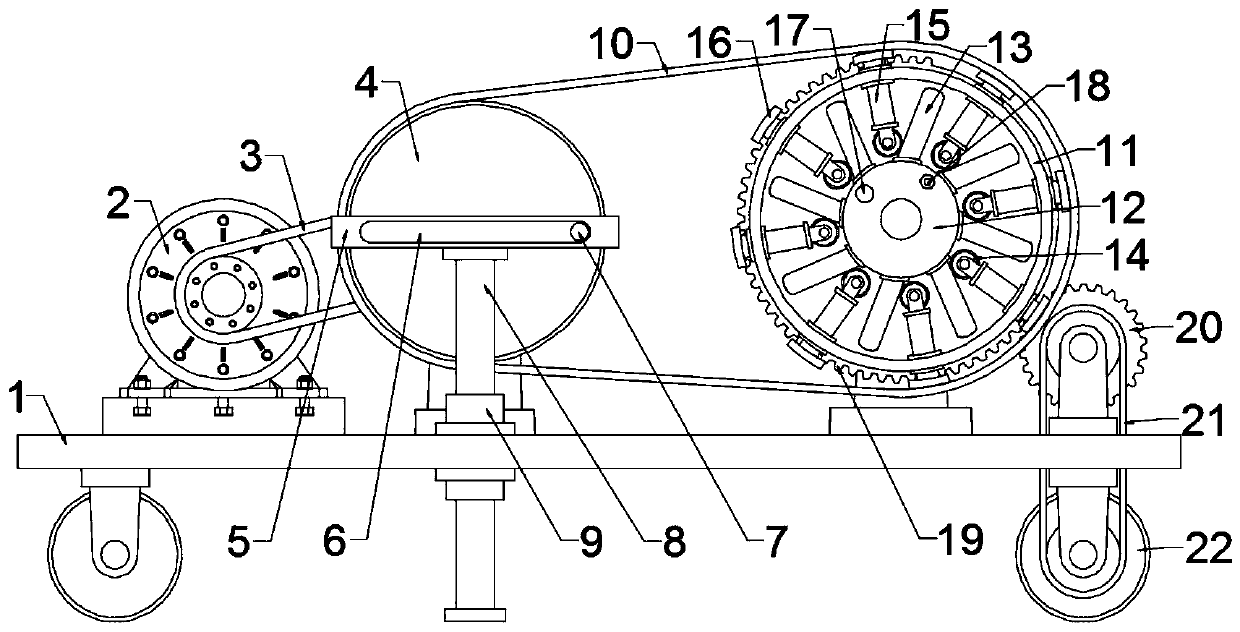

[0021] see Figure 1~3 , in an embodiment of the present invention, an equidistant piling machine with adjustable transmission ratio, comprising a vehicle board 1, a driving motor 2 installed on the vehicle board 1 and connected to a power supply and a switch by wires, and a drive wheel arranged on the top of the vehicle board 1 to rotate 4. The piling mechanism connected to the driving wheel 4, the drum 11 connected to the driving wheel 4 through the second transmission member 10, and the driving wheel 22 connected to the drum 11 by intermittent transmission;

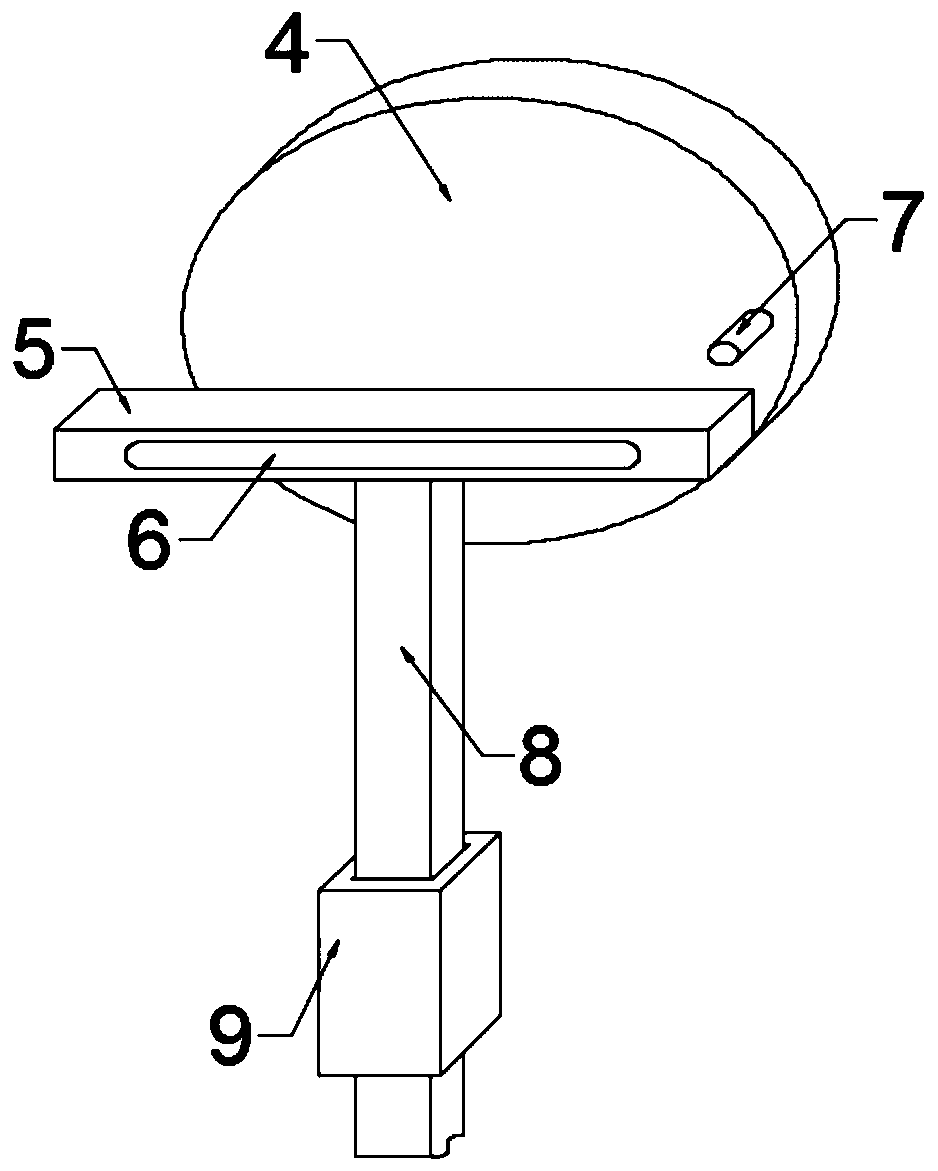

[0022] Specifically, the piling mechanism includes a limit column 7 fixed on the outer edge of the side of the driving wheel 4, a guide groove 6 fitted with the limit column 7 provided on the top plate 5, a punch 8 fixed below the top plate 5, The sleeve 9, which is combined with the punch rod 8 and fixed on the vehicle plate 1, uses the first transmission member 3 to drive the driving wheel 4 to rotate after the drive...

Embodiment 2

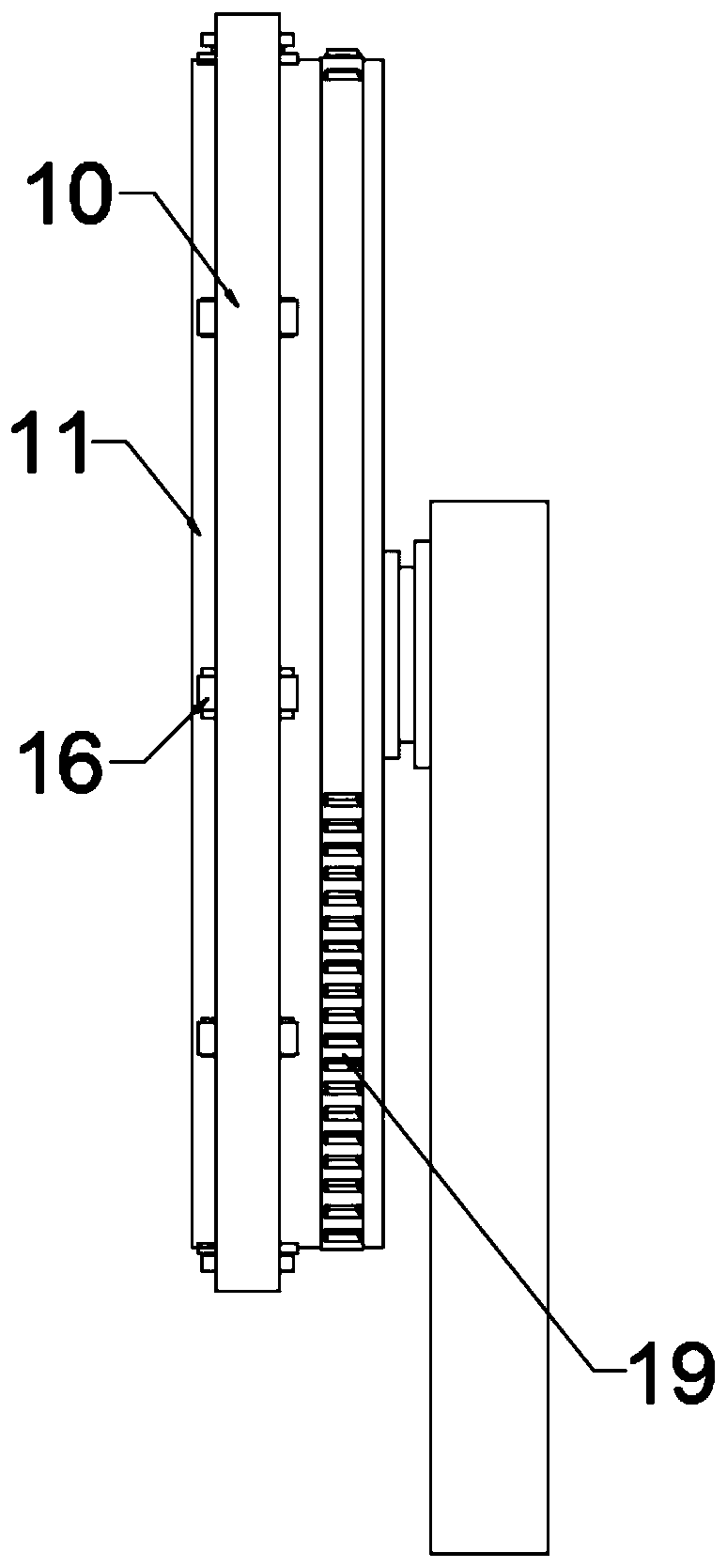

[0026] In order to further limit the intermittent transmission mode between the drum 11 and the driving wheel 22 in the above embodiment, in another embodiment of the present invention, an equidistant pile driver with an adjustable transmission ratio, the outer wall of the drum 11 is fixedly connected with a section There is a toothless residual tooth ring 19, and a gear 20 is rotated on the vehicle plate 1, and the gear 20 meshes with the toothed part of the residual tooth ring 19, and the gear 20 and the driving wheel 22 are connected by a third transmission member 21 , use the rotating drum 11 to drive the residual tooth ring 19 to follow the rotation, thereby driving the gear 20 to rotate intermittently, the gear 20 drives the driving wheel 22 to rotate intermittently through the third transmission member 21, and finally drives the intermittent walking of the whole device.

[0027] Wherein, when the toothed part of the residual tooth ring 19 is in contact with the gear 20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com