Clamping anchor for fastening ironwork to hollow profile of window or door

A technology for anchors and iron products, used in threaded fasteners, friction-clamped detachable fasteners, door/window accessories, etc. Desirable, time-saving, quick and easy to install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

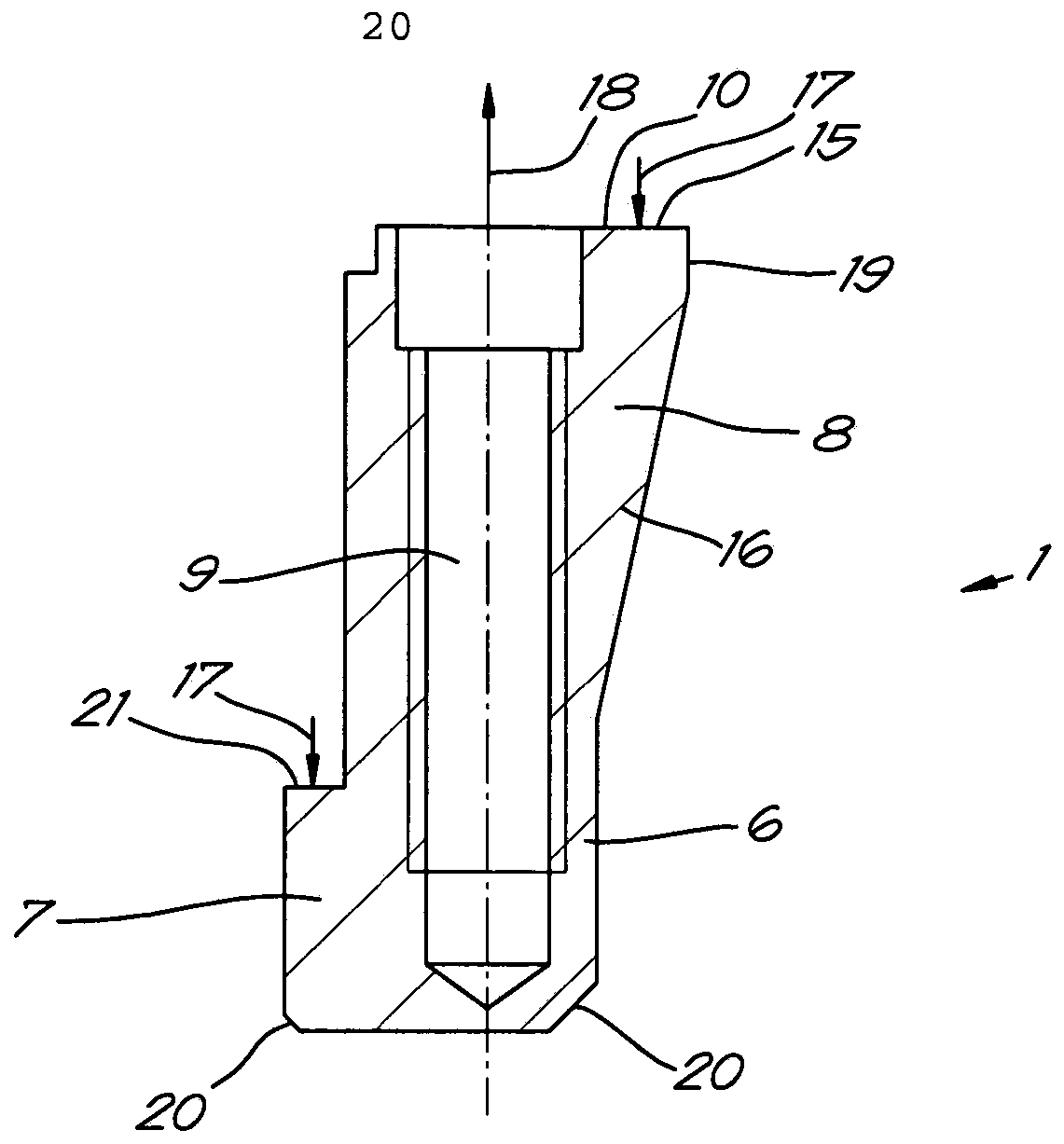

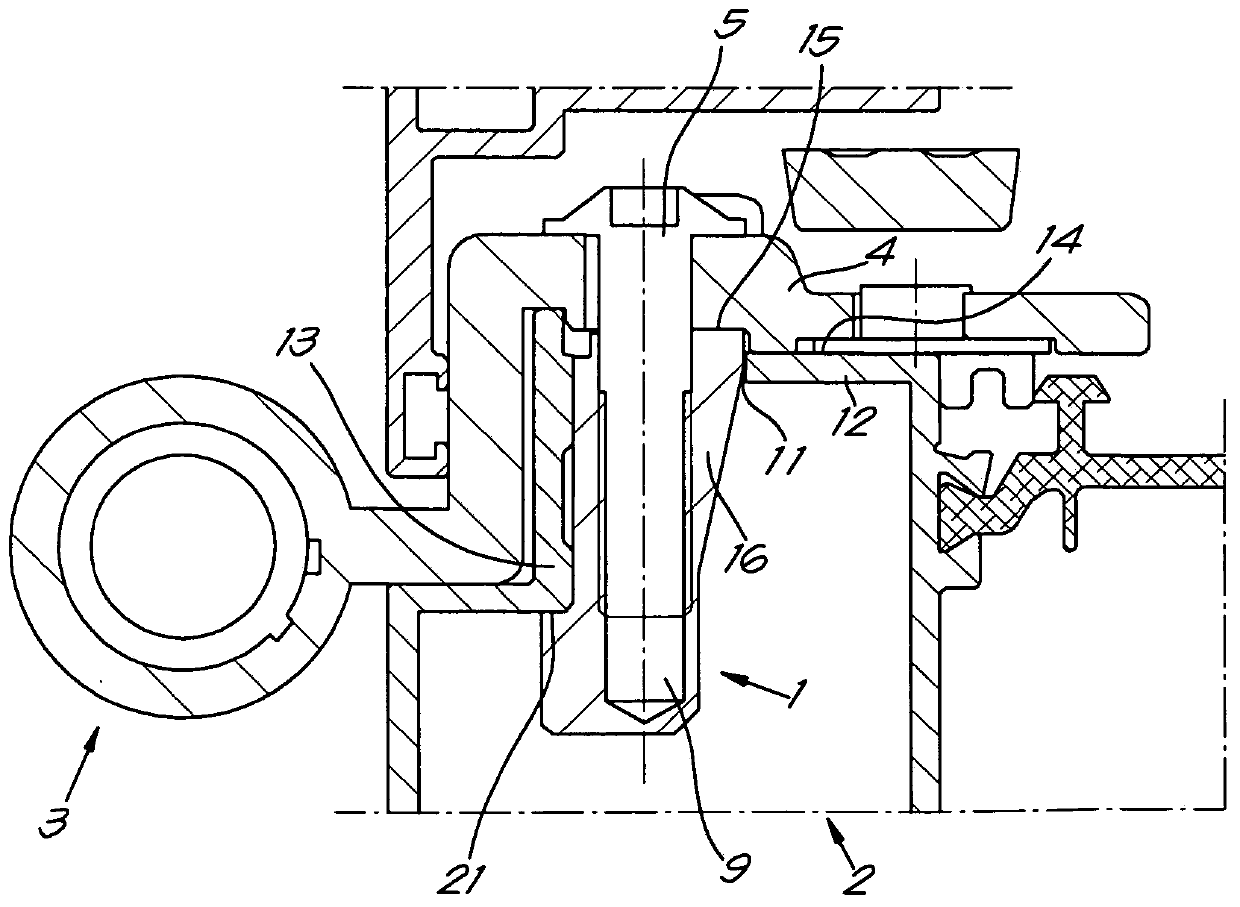

[0062] figure 2 A part of a hinge 3 is shown, a hinge leaf 4 of which is fastened to the hollow profile 2 by means of the clamping anchor 1 according to the invention.

[0063] like figure 1 As shown in more detail in , the clamping anchor 1 basically consists of an L-shaped body 6 having a first leg 7 and a second leg 8 provided with an internal thread 9 along which the extending in the length direction.

[0064] The clamping anchor 1 is oblong with a long leg (second leg 8) and a short leg (first leg 7).

[0065] The bearing surface 15 is located on the free end 10 of the second leg 8 which rests on the hinge leaf 4 when the screw 5 is tightened.

[0066] As shown, this bearing surface 15 can be arranged at the head of the free end 10 of the second leg 8, but the free end 10 can also be shaped so that the bearing surface is not completely at the top, but slightly lowered so that the hinge leaf 4 It is still possible to rest on this support surface.

[0067] The free en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com