Lock nut

A technology for anti-loosening nuts and nut bodies, applied to nuts, screws, bolts, etc., can solve potential safety hazards, loosening and other problems, and achieve the effects of improving stability, avoiding loosening, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

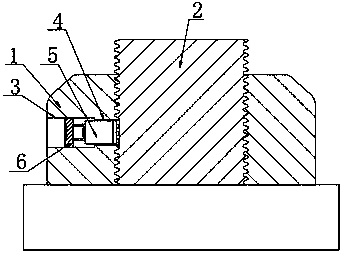

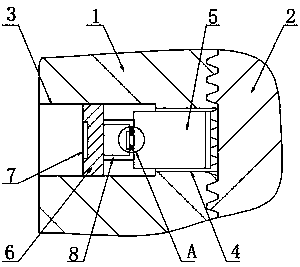

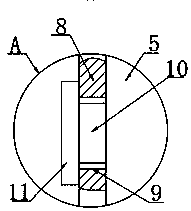

[0021] The present invention provides such Figure 1-3 A locknut shown includes a nut body 1, the inside of the nut body 1 is provided with a bolt 2, the nut body 1 is threaded with the bolt 2, and one side of the nut body 1 is provided with a threaded hole 3. The end of the threaded hole 3 close to the bolt 2 is provided with a chute 4, and the inside of the threaded hole 3 is provided with a threaded block 6, and the threaded block 6 is threadedly connected with the threaded hole 3, and the inside of the chute 4 A cutting block 5 is slidingly connected, and the end of the cutting block 5 close to the bolt 2 is provided with a knife edge, and a U-shaped frame 8 is fixedly installed on the side of the threaded block 6 close to the cutting block 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com