A kind of screw tooling

A technology of screwing and tooling, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problem of workpiece card cannot be taken out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

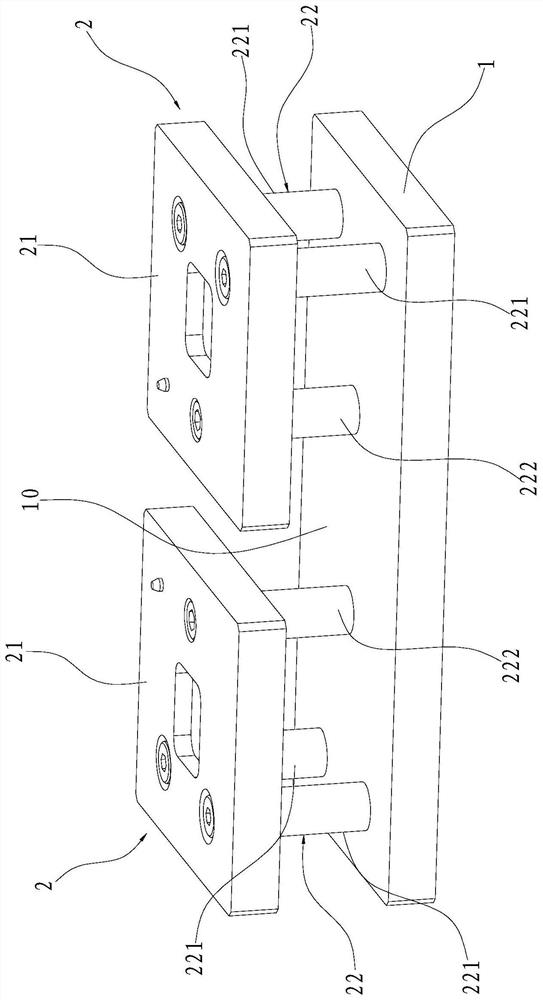

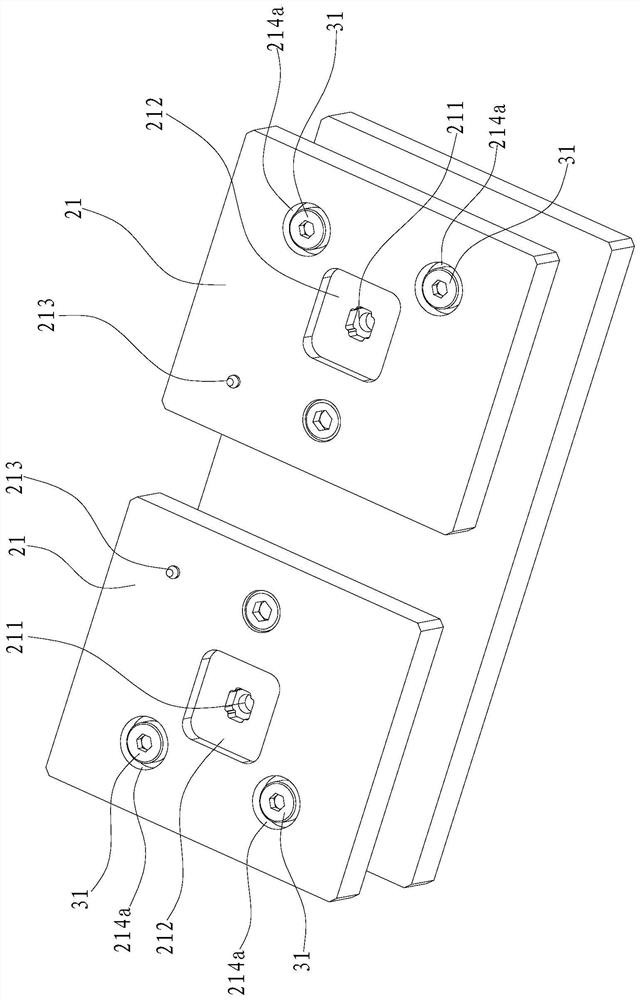

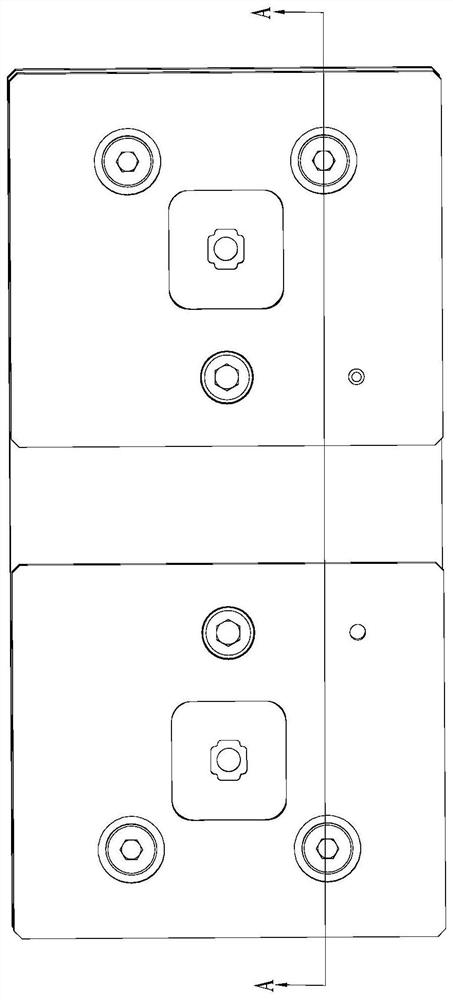

[0025] Such as Figure 1-12 As shown, a screw tooling is used for the assembly of the sound box sealing cover 11, the positioning column 12 and the assembly screw 13. The above-mentioned sound box sealing cover 11 is respectively provided with two installation holes 111 and two positioning holes 112, and the positioning column 12 It consists of upper and lower parts, wherein the upper part 121 has a non-circular cross-section and is axially provided with a blind installation hole 121a for the above-mentioned assembly screw 13 to enter, the lower part 122 is cylindrical, and the upper part 121 protrudes outward along the circumferential direction in section 122 below.

[0026] The above-mentioned screw driving tool includes a workbench 1 with a table top 100, two support seats 2 are arranged side by side on the table top 100, and there is a ga...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap