Anti-reverse method and device for slewing brake and construction machinery

A technology for slewing braking and construction machinery, which is applied to fluid pressure actuation devices, mechanical equipment, fluid pressure actuation system components, etc., and can solve problems such as different and no longer adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

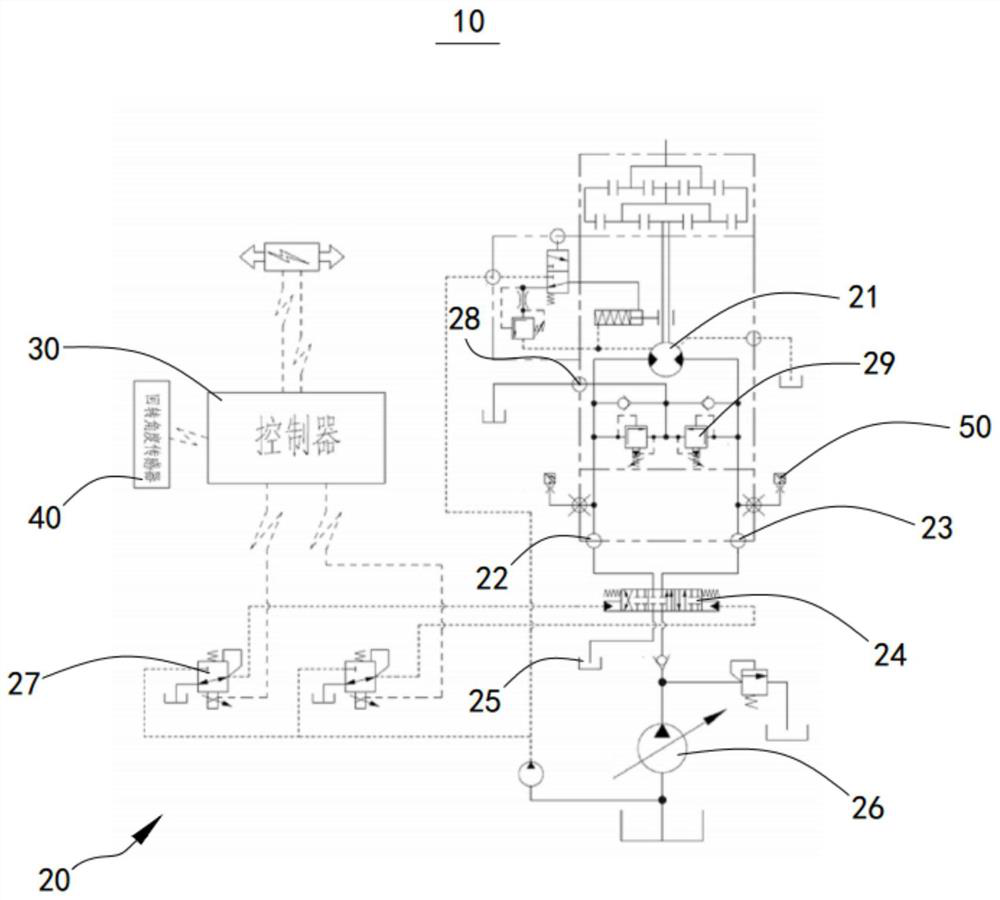

[0052] figure 1 For the structural representation of the engineering machinery 10 provided in this embodiment, please refer to figure 1 The engineering machinery 10 provided in this embodiment includes a body (shown in the figure), a hydraulic circuit 20, a controller 30, a rotational angular velocity sensor 40 and two pressure sensors 50, and the rotational angular velocity sensor 40 is arranged on the rotary mechanism of the hydraulic circuit 20 21 , two pressure sensors 50 are respectively arranged at both ends of the slewing mechanism 21 , and the controller 30 is electrically connected to the slewing angular velocity sensor 40 and the two pressure sensors 50 .

[0053] In the engineering machinery 10 provided in this embodiment, the rotary mechanism 21 in the hydraulic circuit 20 is respectively provided with a first working oil port 22 and a second working oil port 23, and the first working oil port 22 and the second working oil port 23 are respectively It is connected ...

no. 2 example

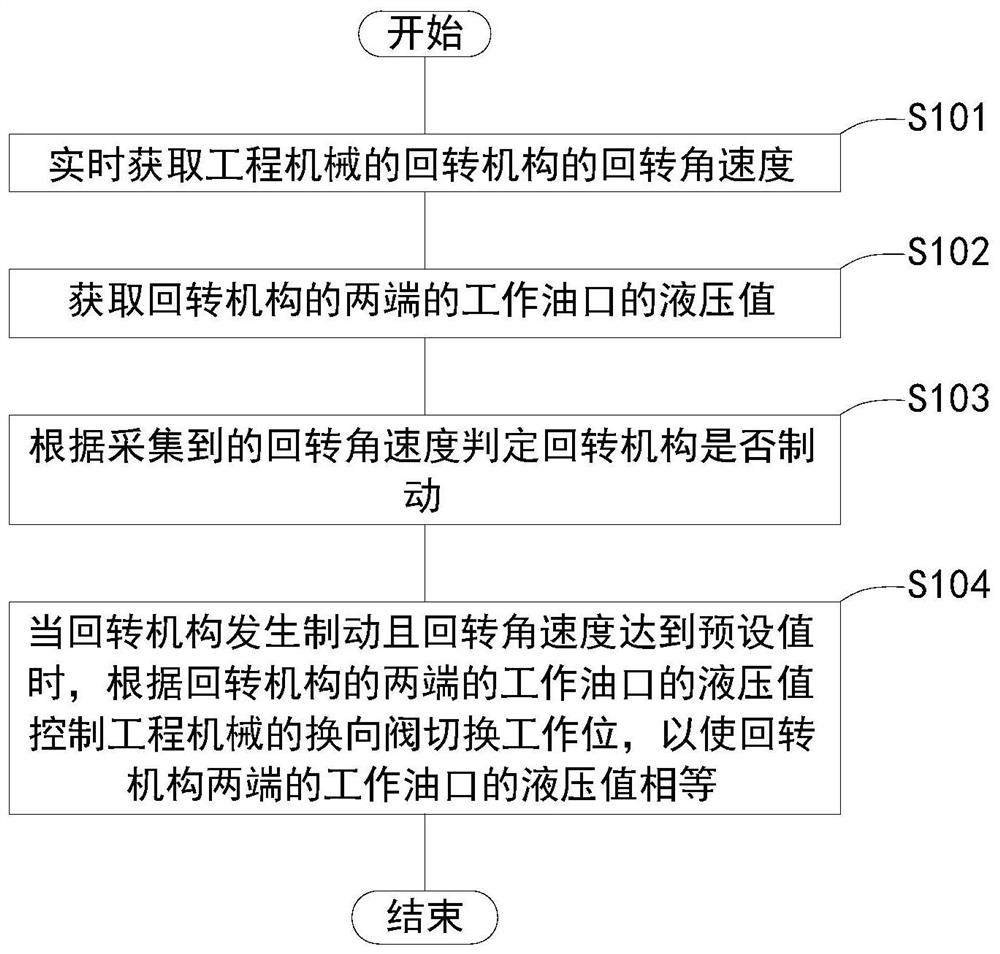

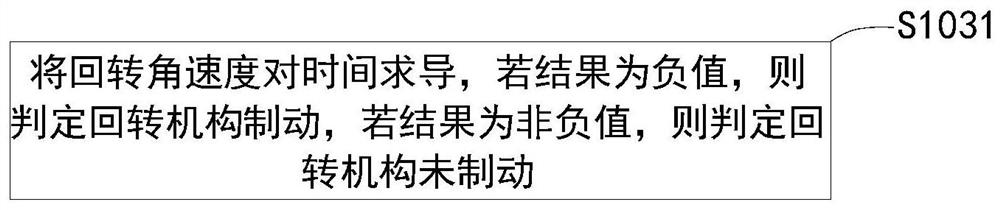

[0058] figure 2 Shown is a schematic block diagram of the flow of the anti-reverse method for slewing braking provided in this embodiment, and the anti-reversing method for slewing braking provided in this embodiment is applied to the construction machine 10 provided in the first embodiment. Please combine figure 1 and figure 2 As shown, the slewing brake anti-reverse method includes the following steps:

[0059] In step S101, the rotational angular velocity of the slewing mechanism 21 of the construction machine 10 is obtained in real time.

[0060] In this embodiment, the rotation angular velocity sensor 40 is arranged on the rotation mechanism 21 , and the controller 30 directly acquires the rotation angular velocity of the rotation mechanism 21 in real time through the rotation angular velocity sensor 40 .

[0061] In other embodiments, a rotation angle sensor can also be provided on the rotation mechanism 21, and the controller 30 can be connected with the rotation a...

no. 3 example

[0093] see Figure 8 , this embodiment provides a slewing brake anti-reverse device 100, which is applied to the construction machine 10 provided in the first embodiment. The slewing brake anti-reverse device 100 includes a first receiving module 110, a second receiving module 130, A determination module 150 and an execution module 170 .

[0094] The first receiving module 110 is configured to obtain the rotational angular velocity of the slewing mechanism 21 of the engineering machine 10 in real time.

[0095] In an embodiment of the present invention, step S101 may be performed by the first receiving module 110 .

[0096] The second receiving module 130 is configured to acquire the hydraulic pressure values of the working oil ports at both ends of the slewing mechanism 21 .

[0097] In an embodiment of the present invention, step S102 may be performed by the second receiving module 130 .

[0098] The determination module 150 is configured to determine whether the slewin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com