Patents

Literature

62results about How to "Improve job adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

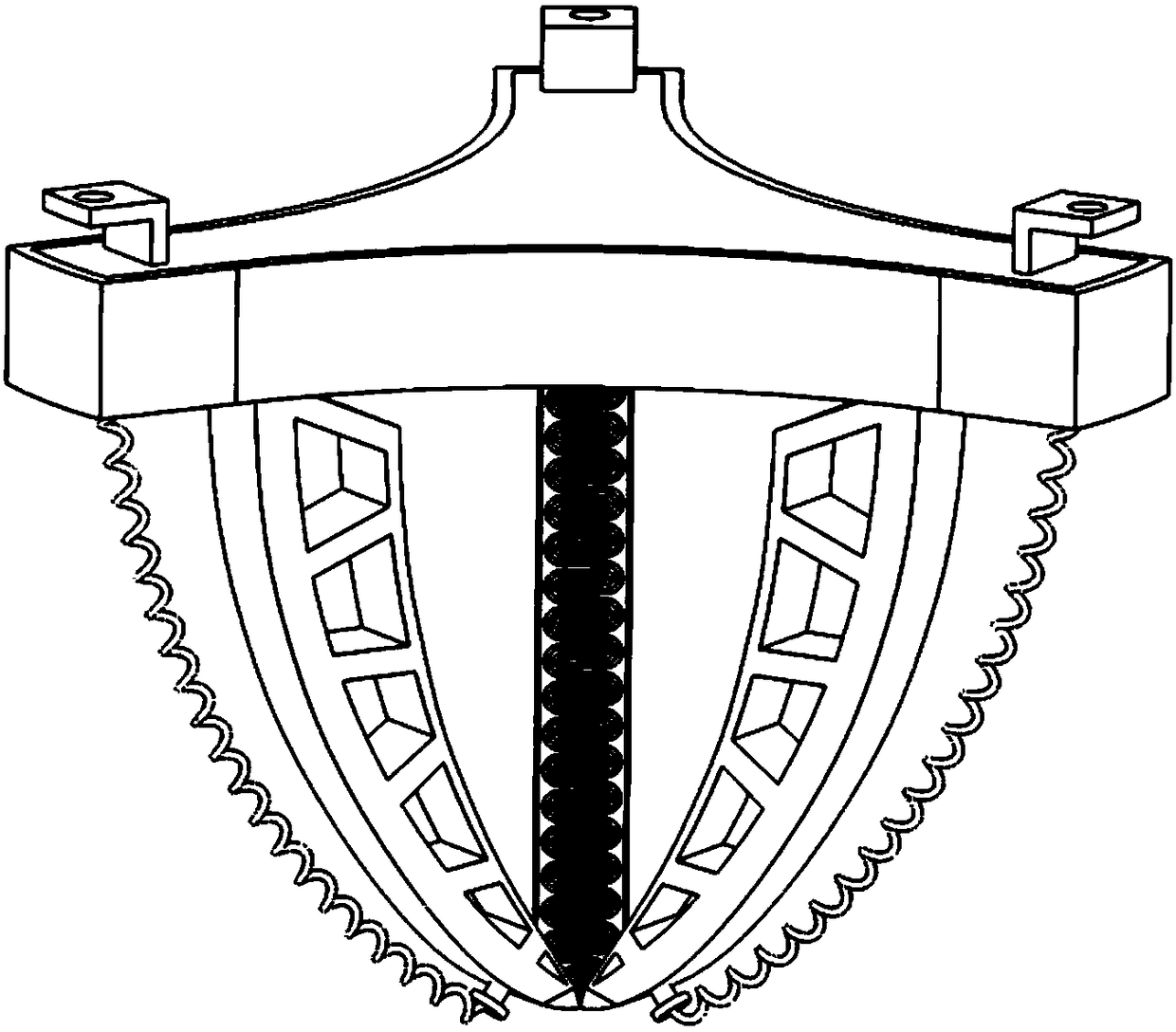

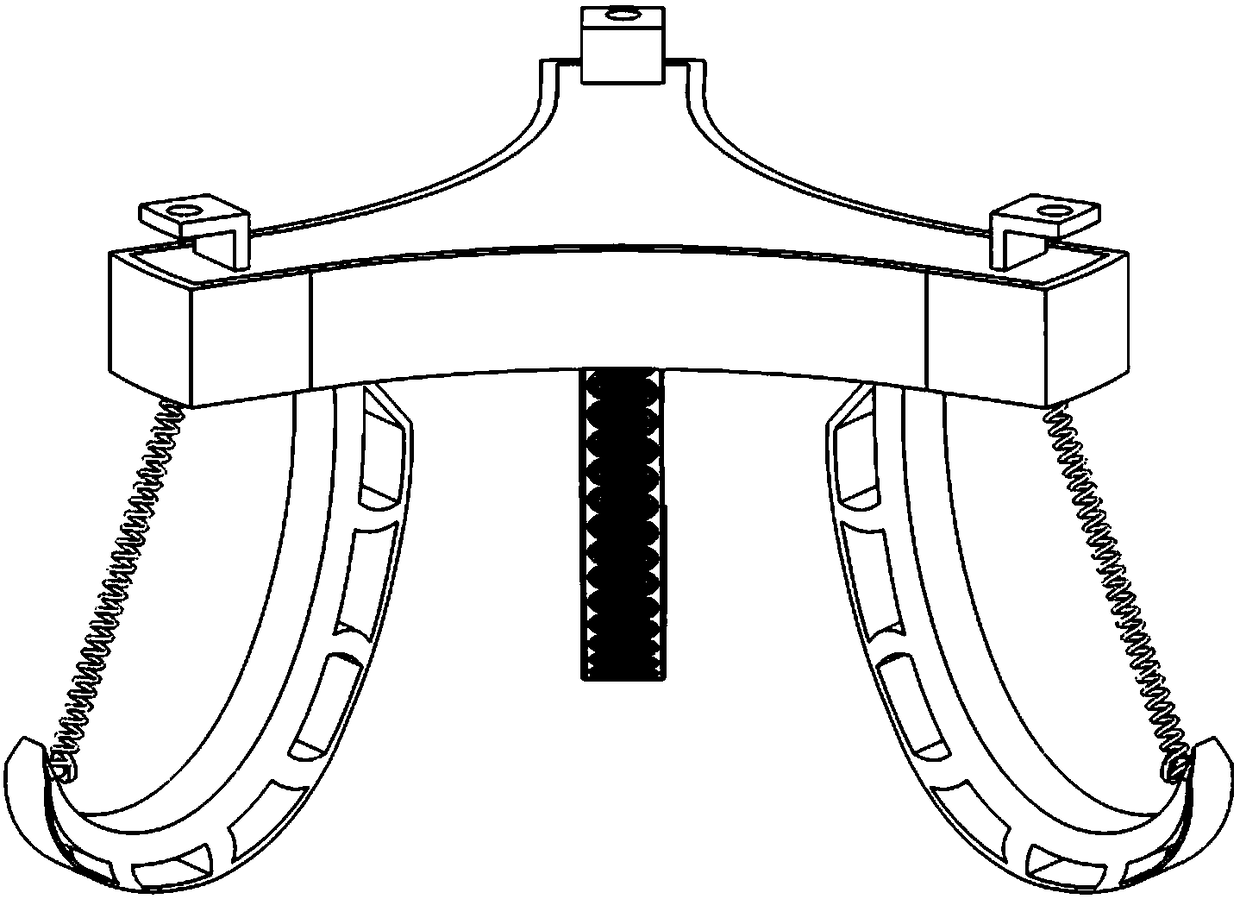

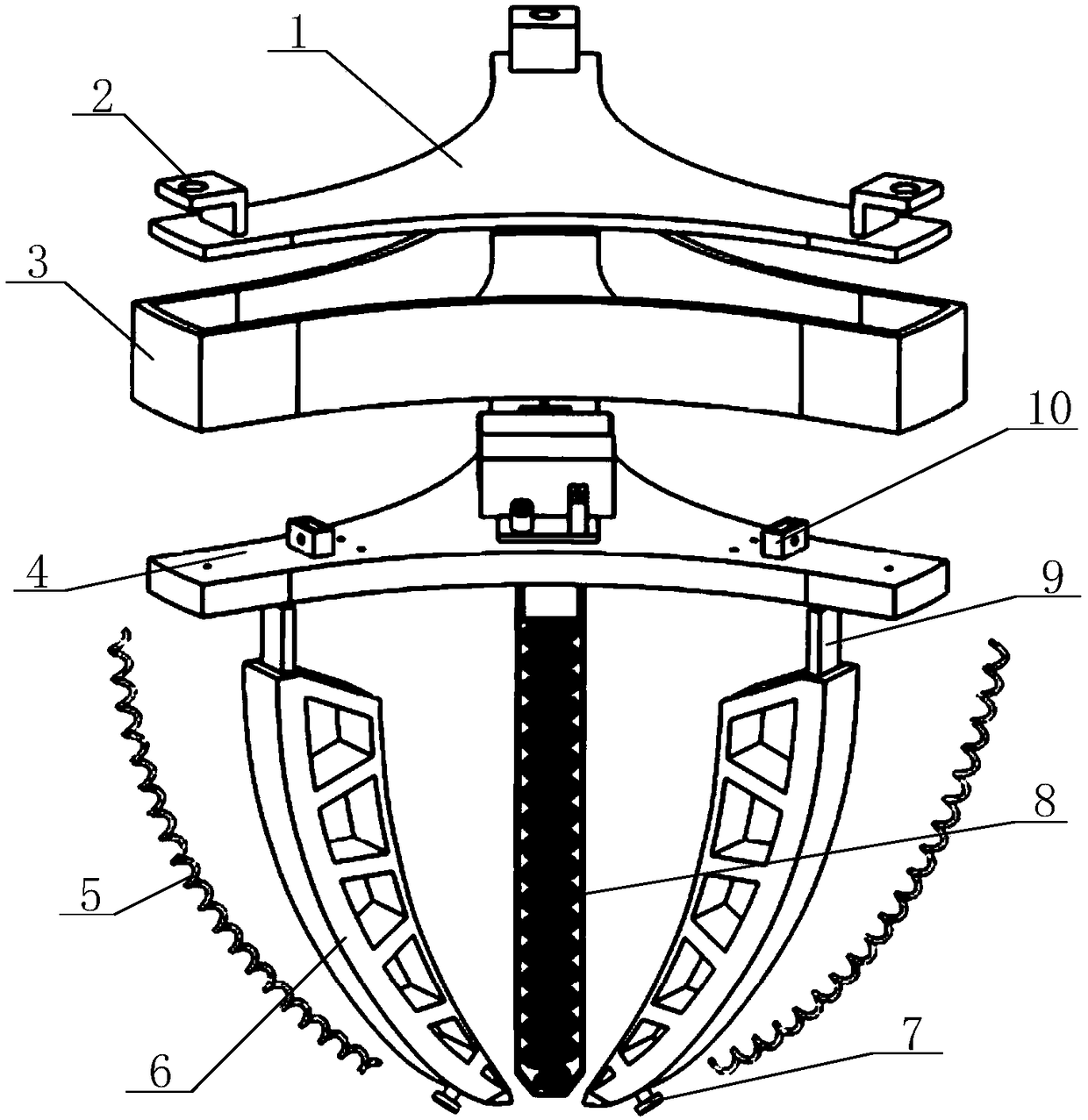

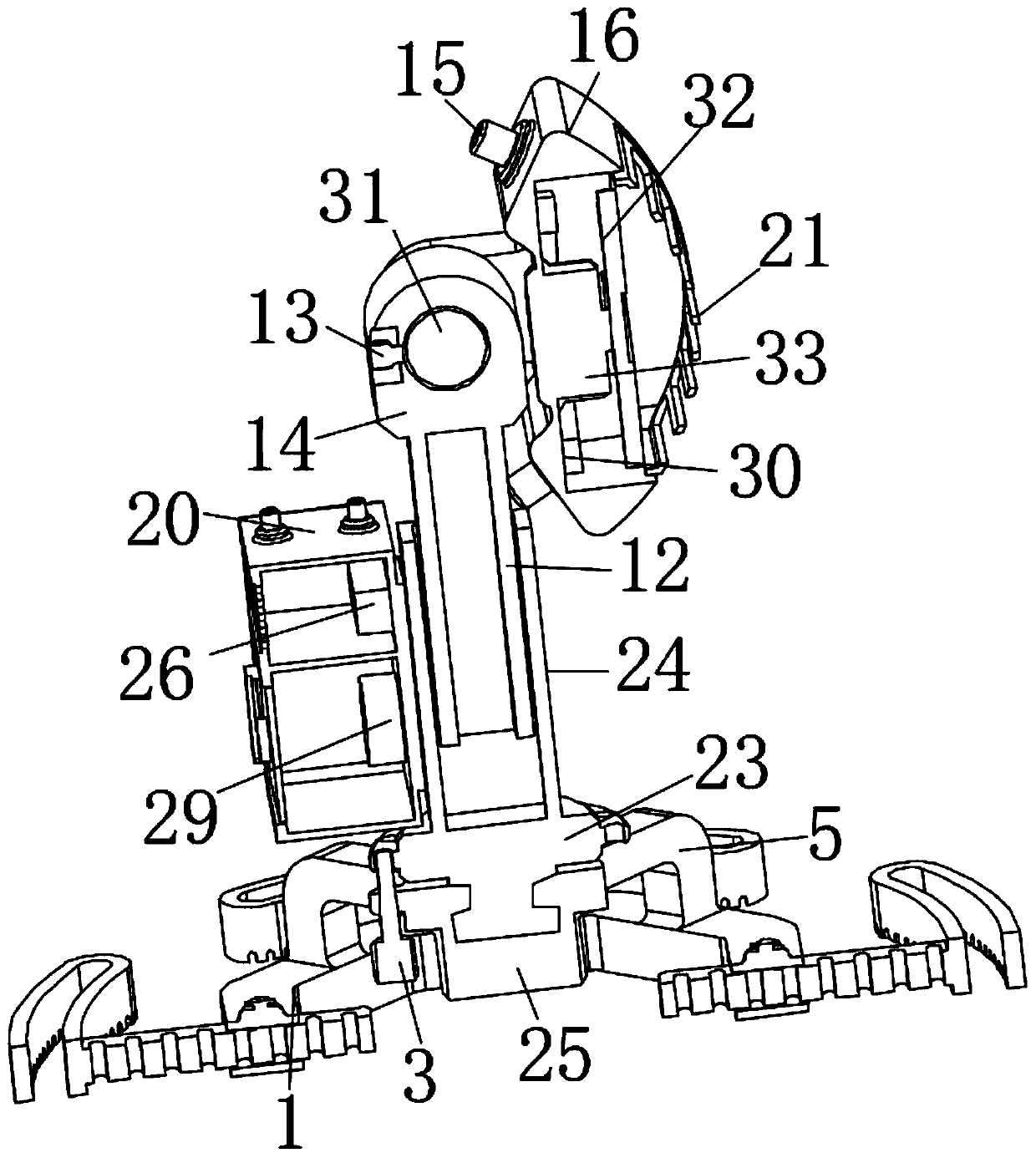

Shape memory alloy driven electrostatic adsorption flexible gripper

ActiveCN108687794AExcellent flexibility and anti-fatigue propertiesGood job adaptabilityGripping headsElectrostatic adsorptionEngineering

The invention discloses a shape memory alloy driven electrostatic adsorption flexible gripper. The shape memory alloy driven electrostatic adsorption flexible gripper comprises a palm seat, multiple elastic fingers arranged on the palm seat and SMA springs in one-to-one corresponding connection to the elastic fingers; the elastic fingers are closed in the free state, the SMA springs are powered on, the elastic fingers connected with the springs are pulled outwards, the elastic fingers are opened, each elastic finger comprises a finger body formed through silicone curing and an elastic rib embedded in the finger body, and the elastic fingers further comprise worm-comb electrodes arranged on the inner side grabbing faces of the finger bodies. Through shrinking and releasing of the shape memory alloy spring, elastic deforming of the elastic inner ribs and the silicone fingers is driven to achieve opening and closing of the flexible gripper, and in combination with the electrostatic adsorption force of the comb electrodes, flexible laminating and stable grabbing of a grabbed object can be achieved.

Owner:CHONGQING UNIV

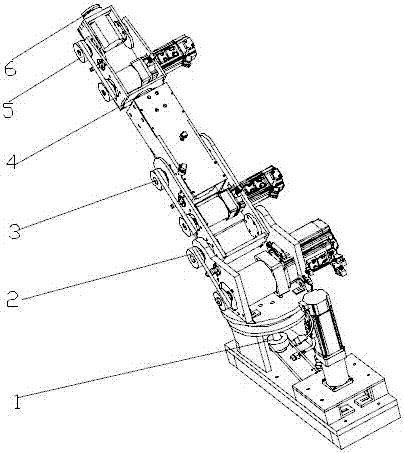

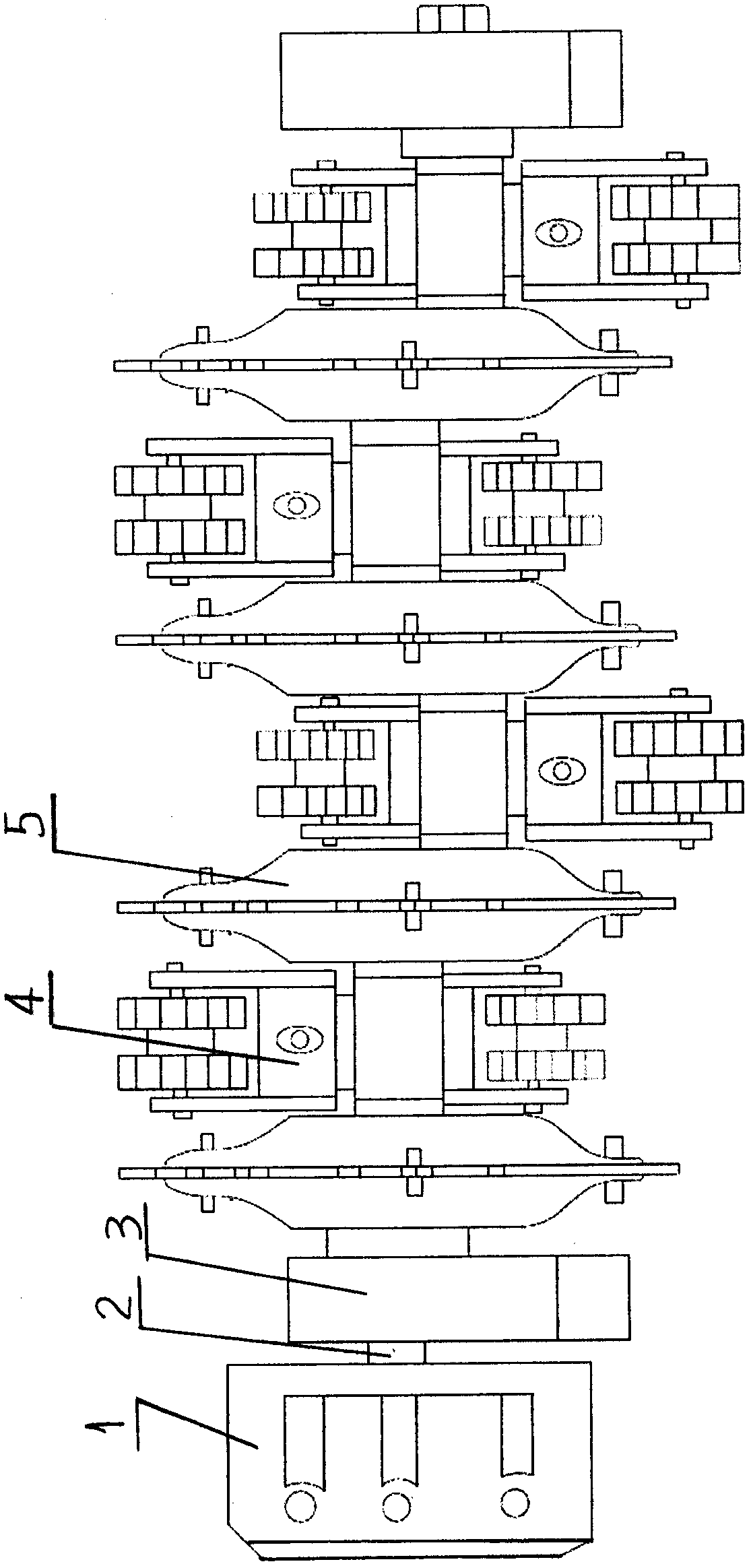

Spliced and inserted type six-degree-of-freedom joint type industrial robot and control system

ActiveCN107414817AReduce weightLow costProgramme-controlled manipulatorTotal factory controlControl systemReducer

The invention relates to a spliced and inserted type six-degree-of-freedom joint type industrial robot which comprises a first rotating joint (1), a second rotating joint (2), a third rotating joint (3), a fourth rotating joint (4), a fifth rotating joint (5) and a sixth rotating joint (6). The joints are installed in a spliced and inserted mode. The power transfer way of the first rotating joint (1), the second rotating joint (2), the third rotating joint (3) and the fifth rotating joint (5) is achieved through a servo motor, a speed reducer, a synchronous wheel, a synchronous belt and a tension mechanism. The power transfer way of the fourth rotating joint (4) and the sixth rotating joint (6) is achieved in the mode that a motor directly drives a flange shaft. The spliced and inserted type six-degree-of-freedom joint type industrial robot has the advantages of being simple in structure, low in manufacturing cost, stable and reliable in performance, high in precision, wide in application range and the like, and the problems that industrial robots in China are large in mechanical body weight, high in cost and the like can be effectively relieved.

Owner:BAISHAN POWER SUPPLY COMPANY OF STATE GRID JILIN ELECTRONICS POWER COMPANY

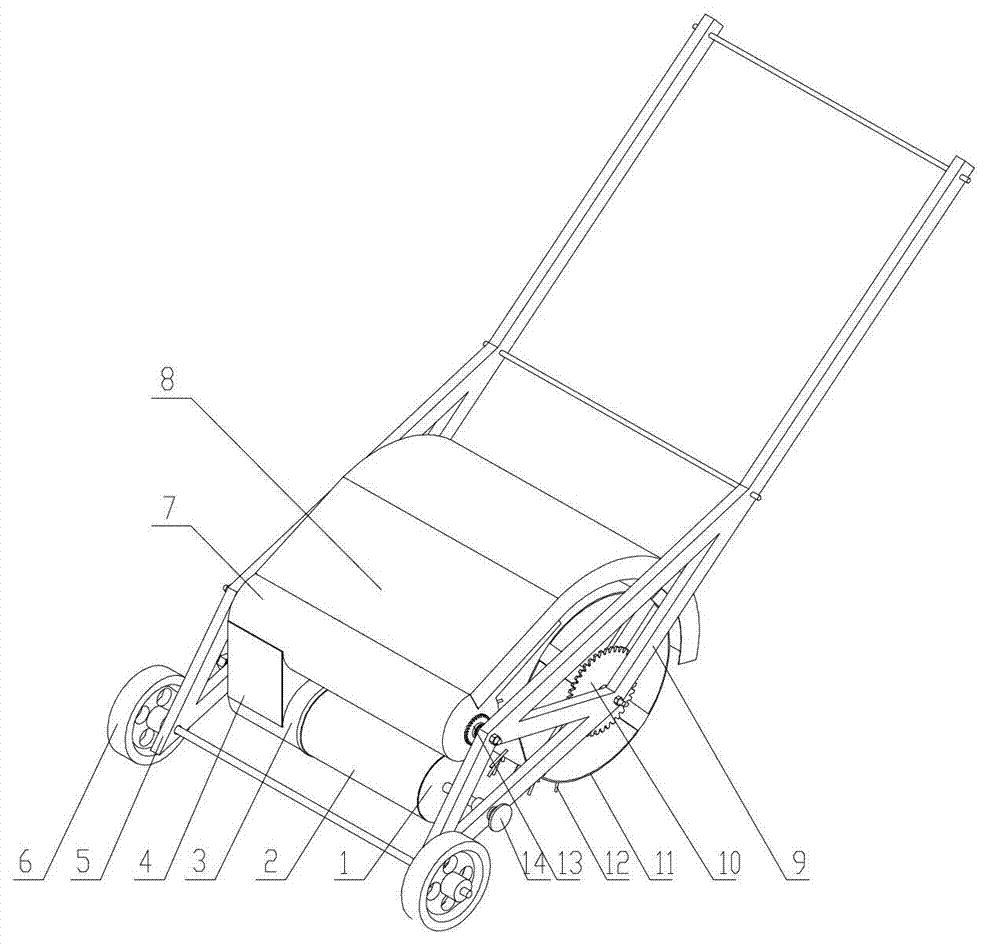

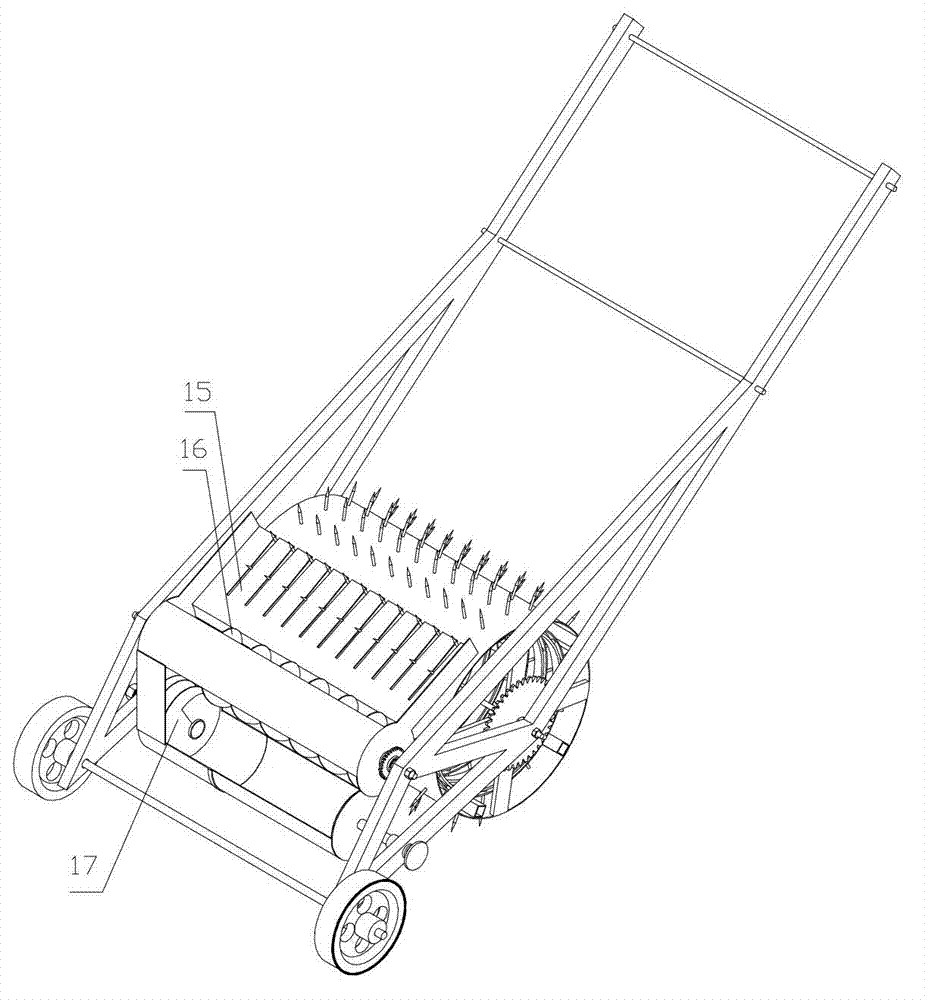

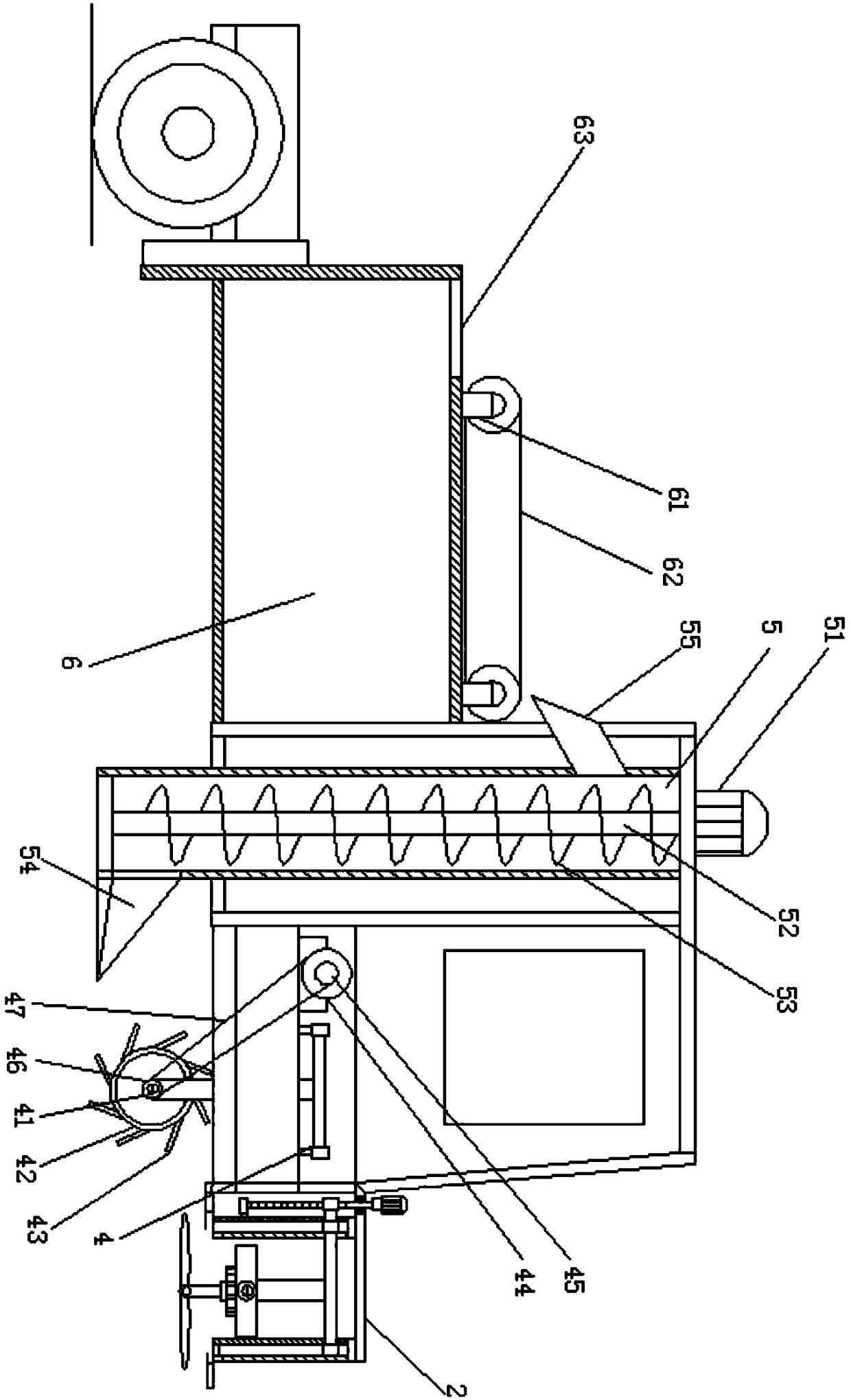

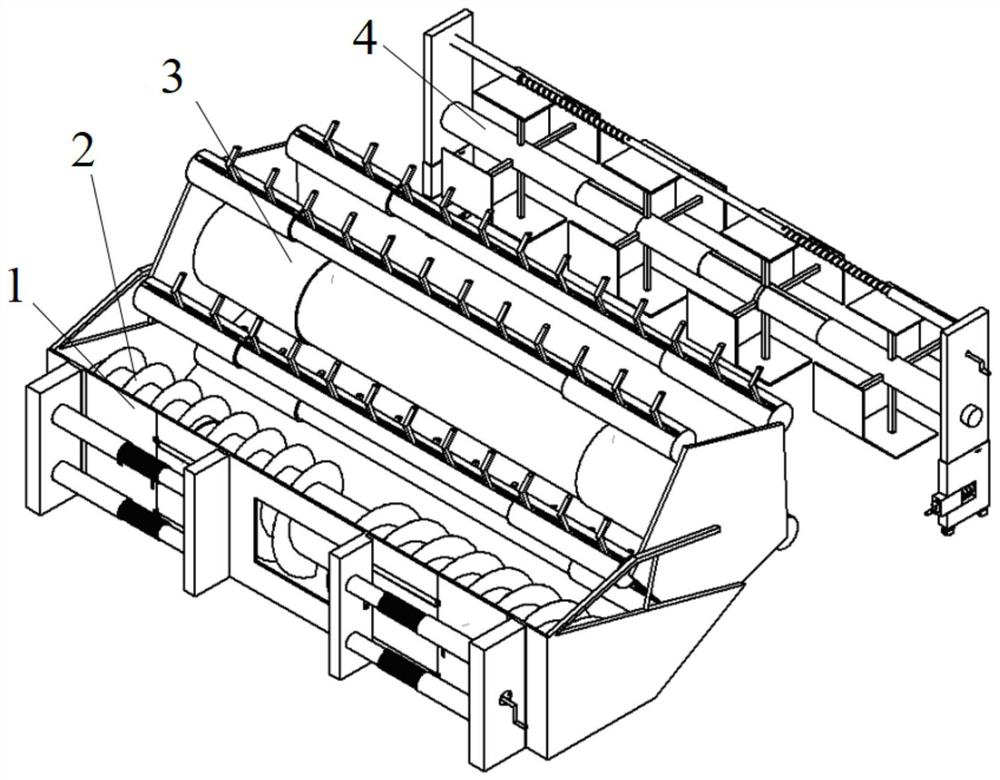

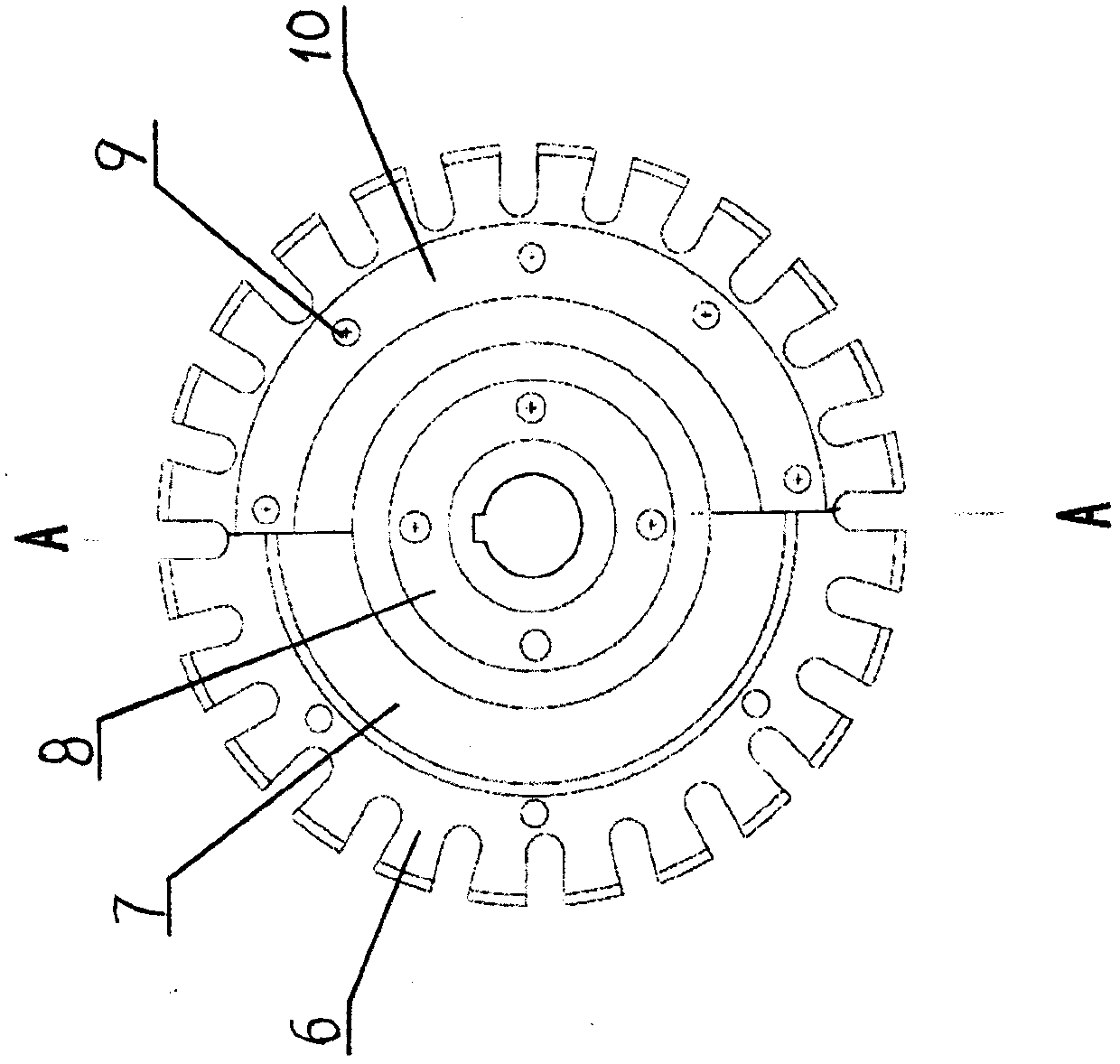

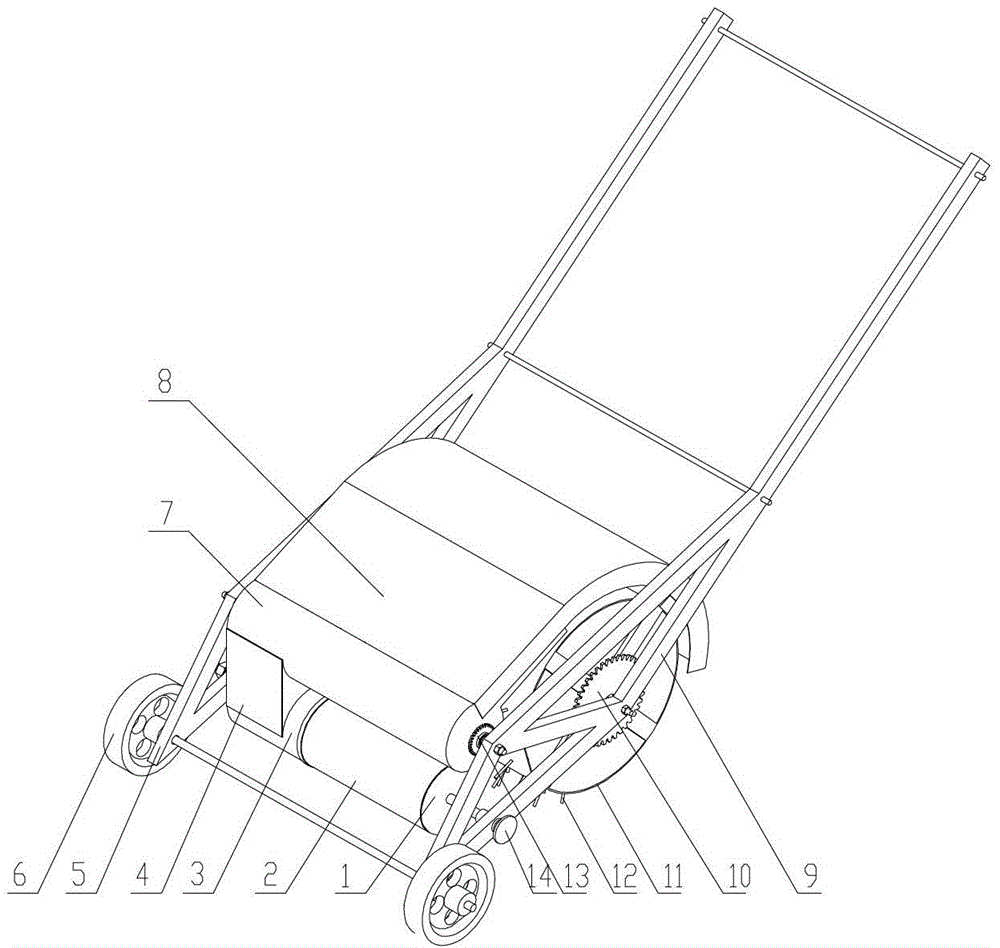

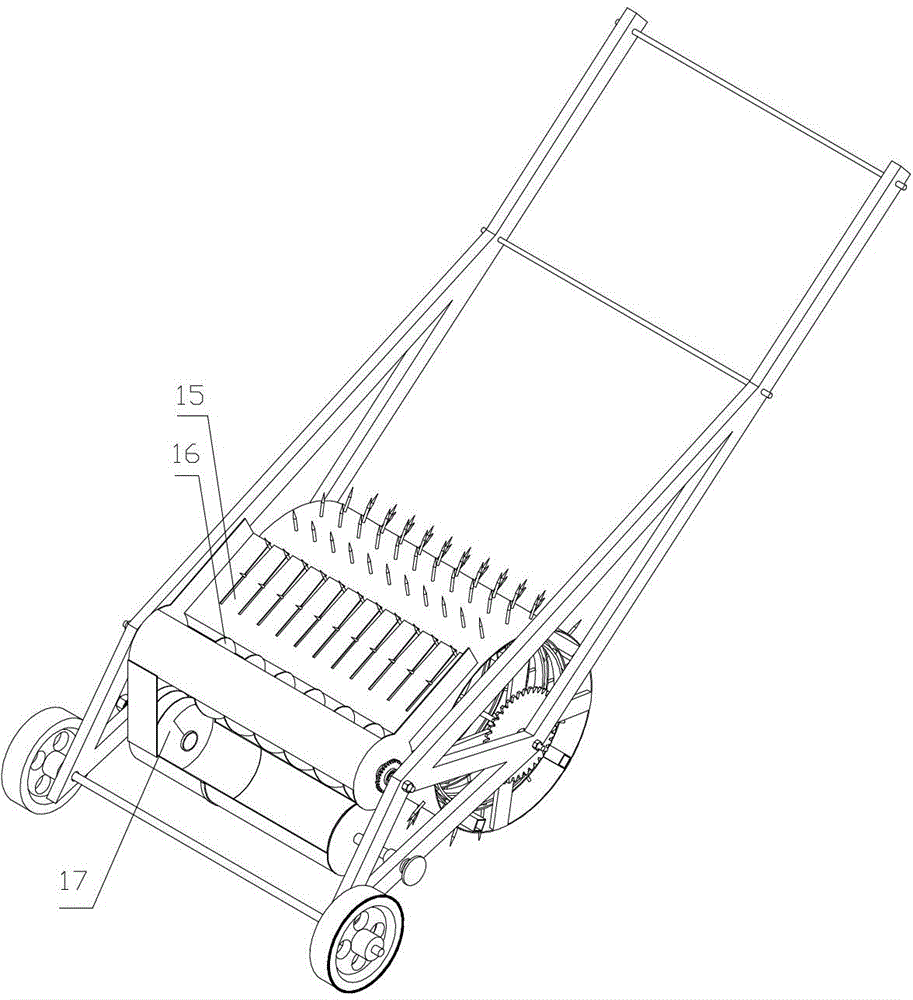

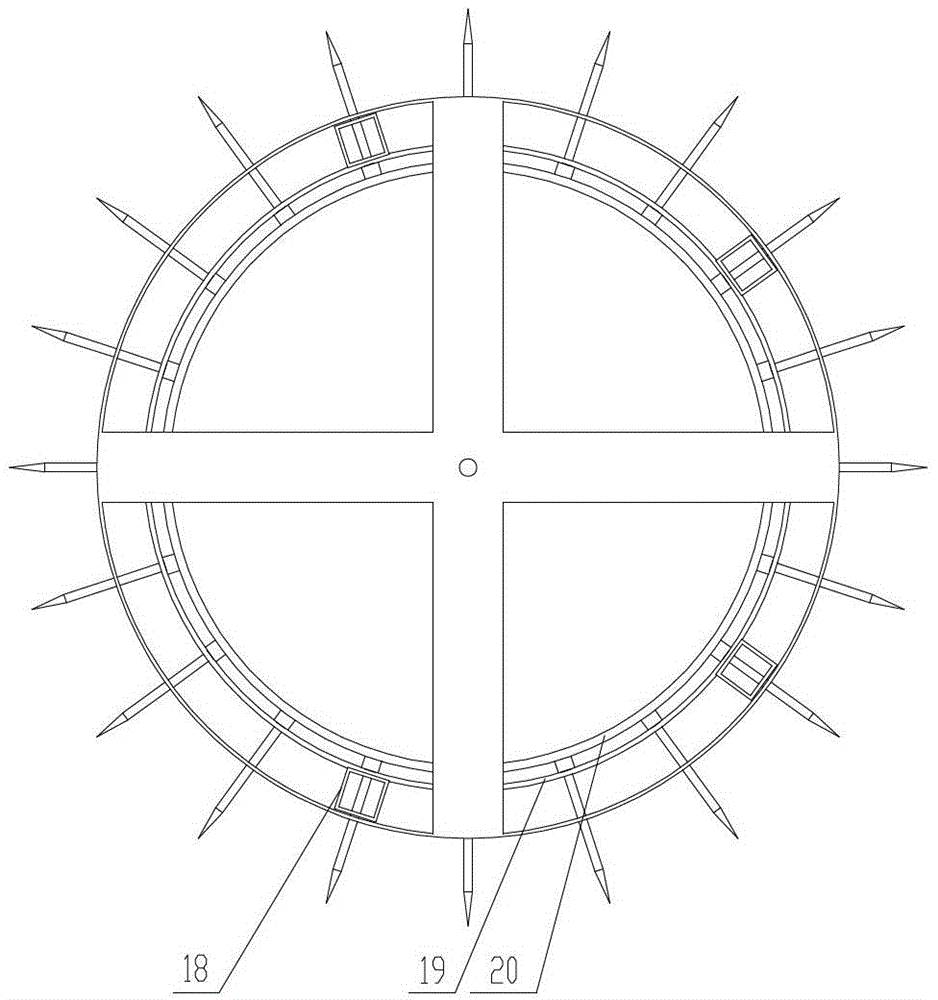

Leaf pickup and compression device for lawns

The invention relates to a leaf pickup and compression device for lawns. The leaf pickup and compression device comprises carriers, wheels, a guard plate and a pickup device. The wheels are fixed at front ends of the carriers, the pickup device is arranged on the rear between the carriers, and the guard plate is mounted above the pickup device. The leaf pickup and compression device travels on a lawn, needle teeth on the pickup device contacts with the ground to directly pick leaves up. When the needle teeth with leaves move into corresponding grooves of a scraping plate, leaves can be taken off into a propelling barrel, a propelling helical blade rotates to extrude leaves to one end, and the leaves can fall into a main compression barrel through a square connecting barrel. A main compression helical blade in the main compression barrel rotates to press the leaves into a replaceable barrel. When extrusion is at certain density, an adjusting rod is rotated to take off the replaceable barrel, and another replaceable barrel is replaced to operate continuously. During operating of the compression device, the leaves and other biomasses can be directly picked up and extruded. The leaf pickup and compression device is low in cost, high in production efficiency and operating adaptability, and widely applicable to popularization and application.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Intelligent light swing arm type crane

Owner:HENAN SINOKO CRANES

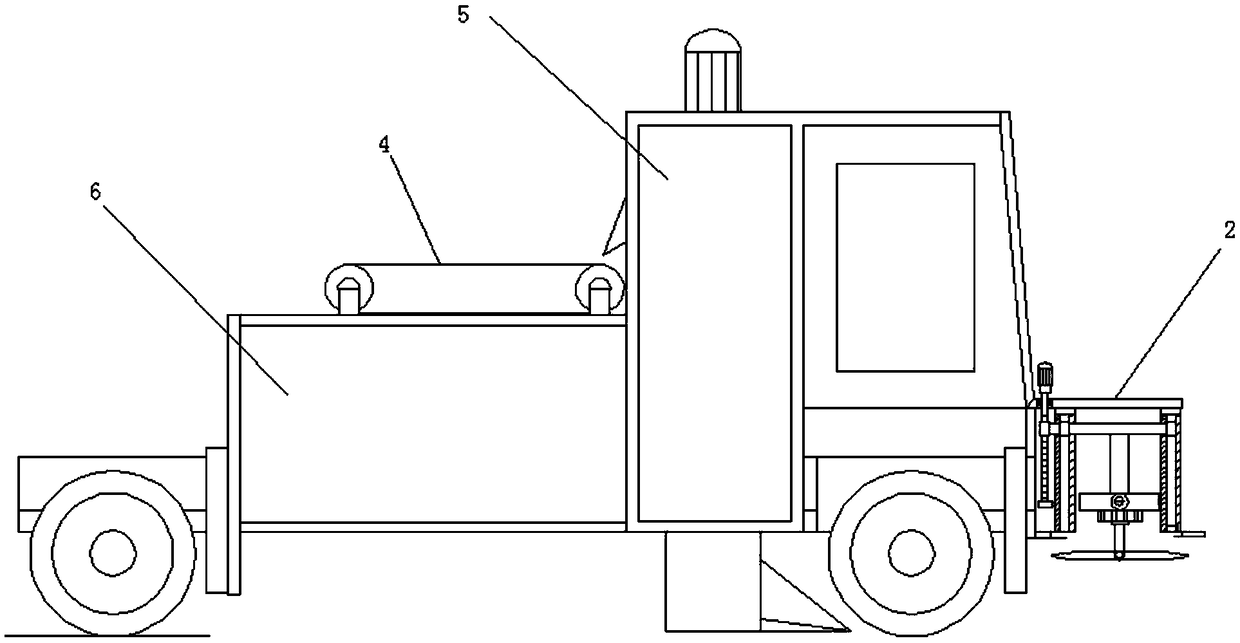

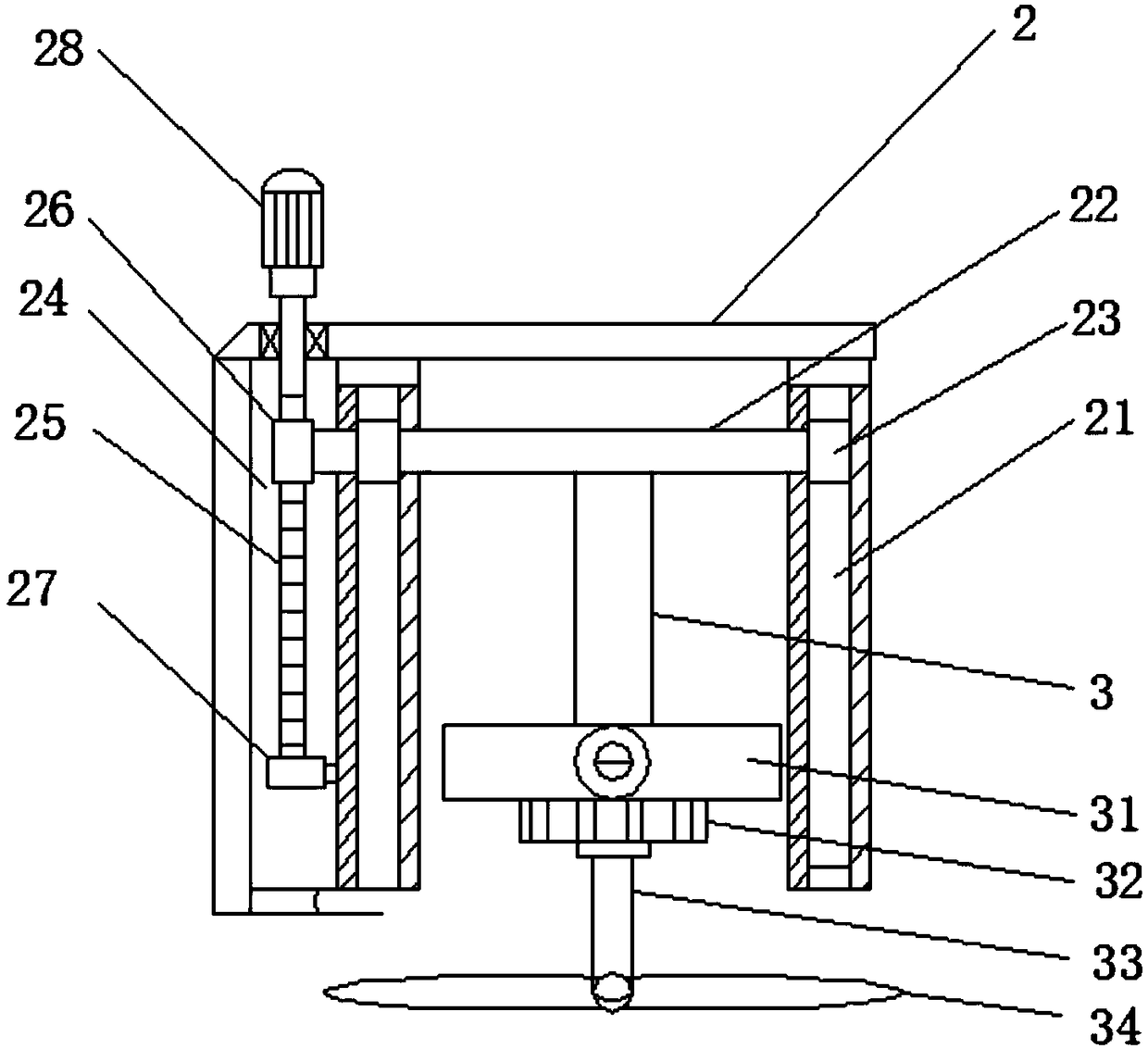

Grass cutting vehicle for collecting forage

InactiveCN108811685AEasy to process and useMaximize utilizationMowersAgricultural engineeringThreaded rod

The invention discloses a grass cutting vehicle for collecting forage. The grass cutting vehicle comprises a vehicle seat; a grass cutting frame, a material pushing frame, a material conveying chamberand a material receiving chamber are separately arranged on the vehicle seat; the grass cutting frame is arranged at the front end of the vehicle seat; the front side wall and the rear side wall of the grass cutting frame are each provided with a guide groove; a movable plate is transversely arranged on the grass cutting frame; the left end and the right end of the movable plate are separately provided with a pulley; each pulley is arranged in one corresponding guide groove; a transmission cavity is arranged in the rear side wall of the grass cutting frame; a threaded rod is vertically arranged in the transmission cavity; the threaded rod is provided with a transmission sleeve; the transmission sleeve is connected with a wheel shaft of the pulley at the rear end through a connecting block; the bottom end of the movable plate is provided with a machine frame; a cutting motor is fixedly arranged on the machine frame; and the bottom end of the cutting motor is provided with cutter bladesthrough a rotating shaft. According to the invention, the grass cutting height can be automatically adjusted by a screw transmission mechanism, the grass cutting vehicle is suitable for operation inareas with different height, and the operation adaptability is greatly improved.

Owner:陈海荣

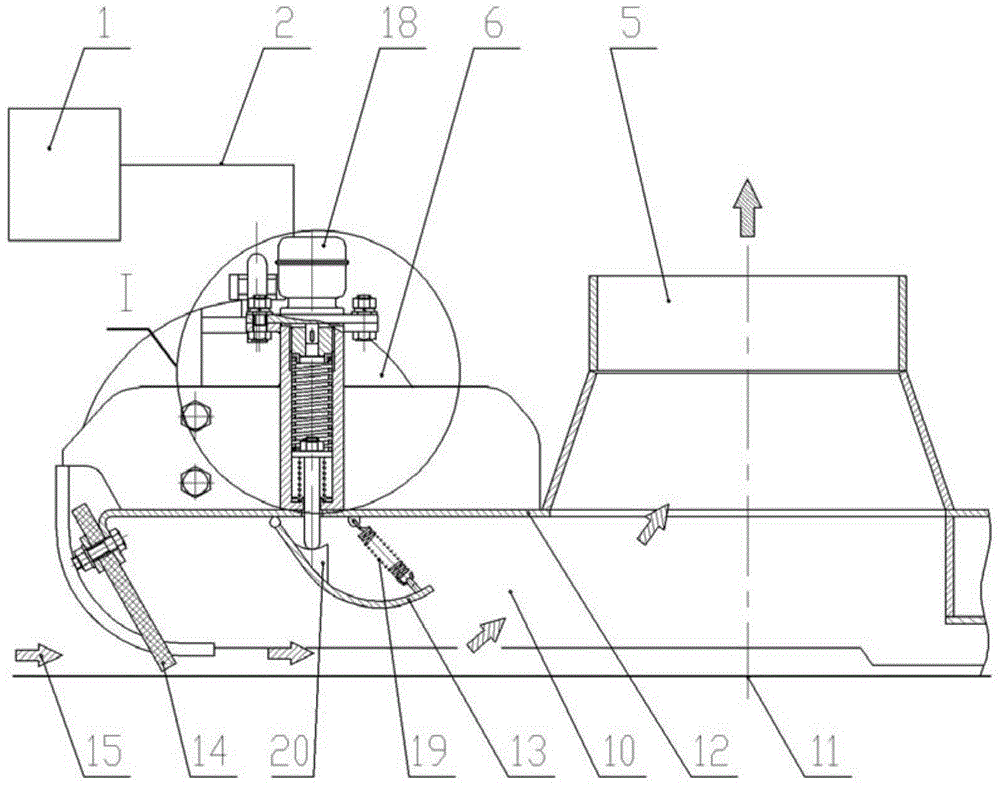

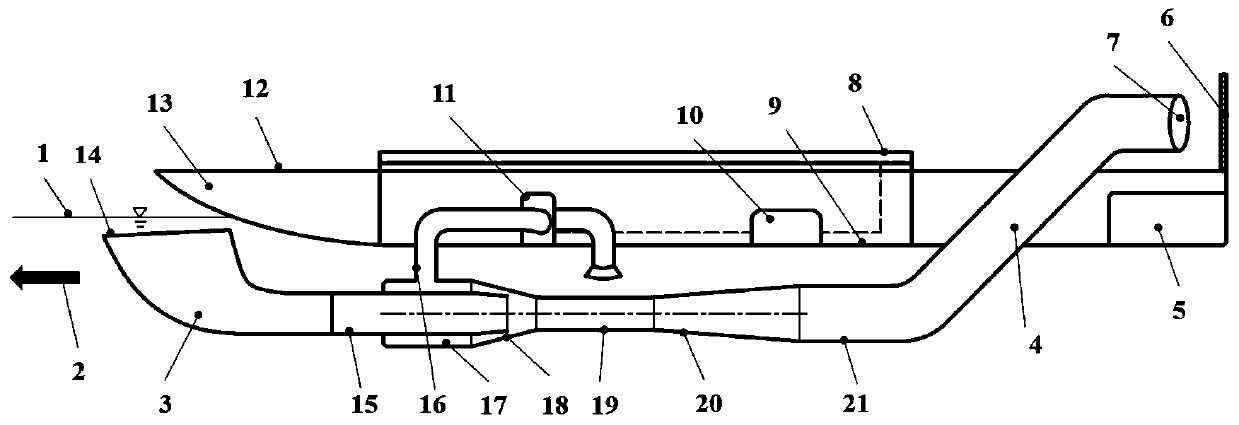

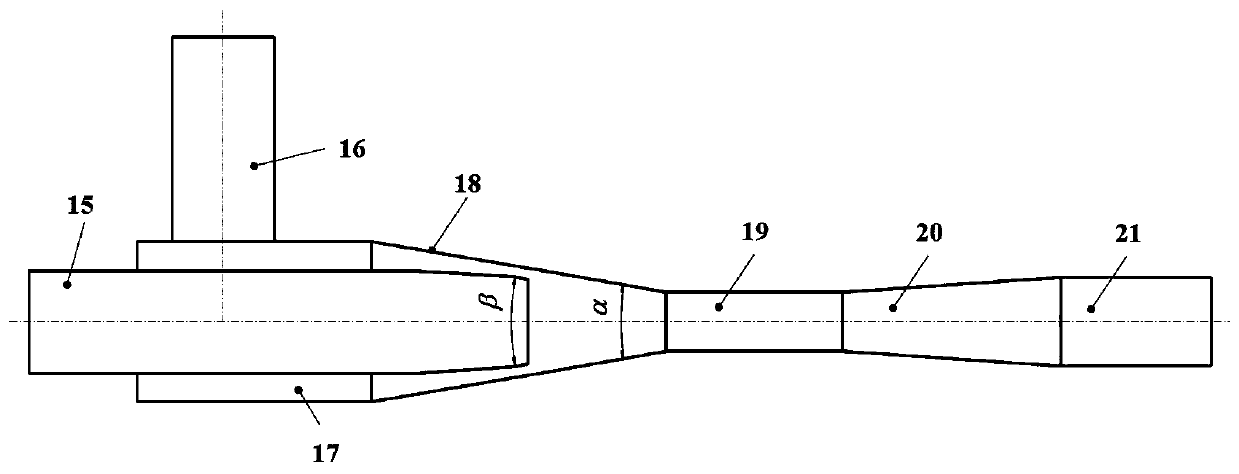

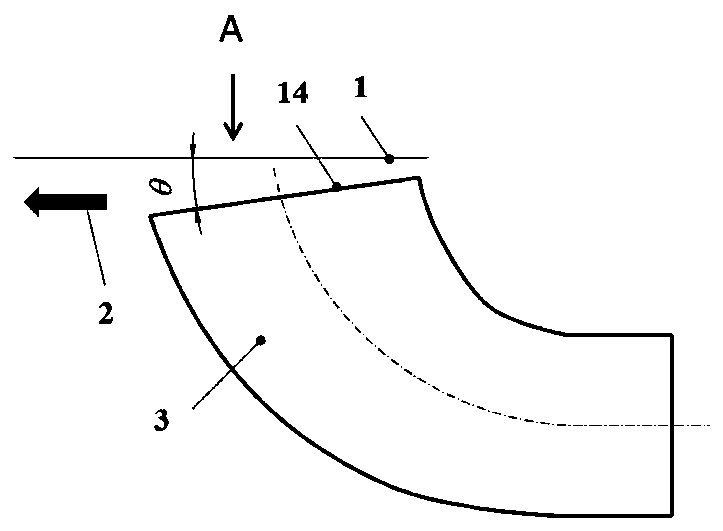

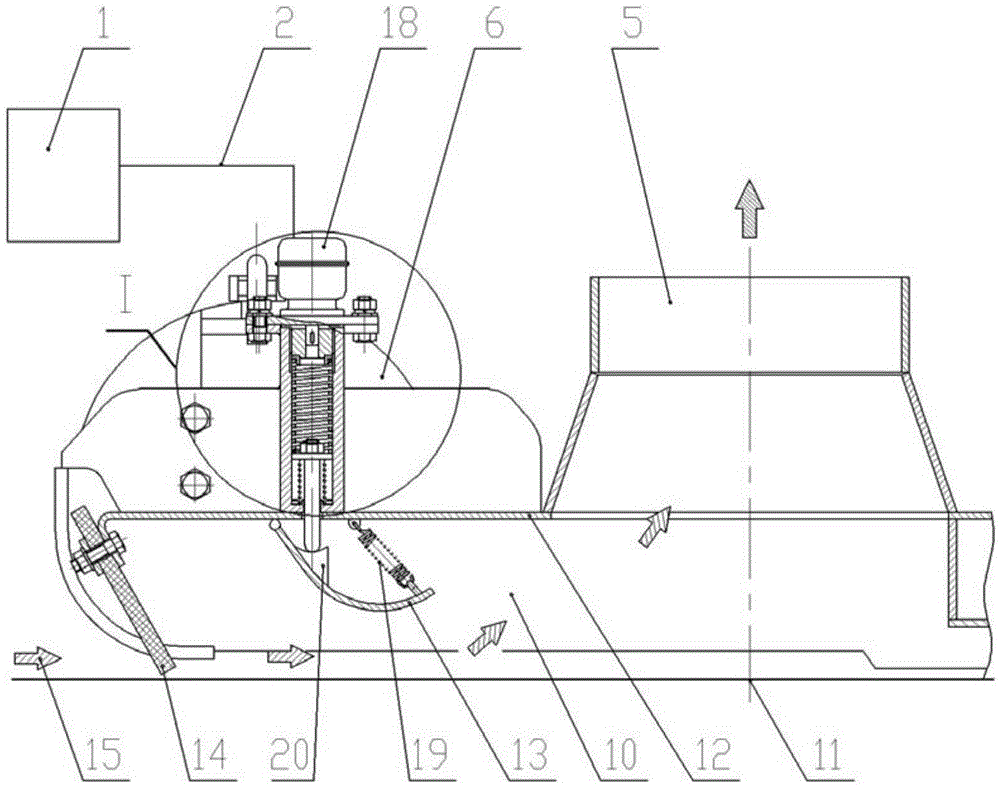

Variable flow area suction nozzle applied to road sweeper

The invention discloses a variable flow area suction nozzle applied to a road sweeper. The variable flow area suction nozzle comprises a suction nozzle body and a conveying pipe arranged on the suction nozzle body, as well as a front air baffle plate arranged at the front end of the suction nozzle body and a rear air baffle plate at the back end of the suction nozzle body, wherein air inlet passages are formed between the bottom ends of the front air baffle plate and the rear air baffle plate and road surface when the sweeper works; a suction inner cavity communicated with the conveying pipe is formed among the suction body, the front air baffle plate and the rear air baffle plate; a tongue plate arranged on the suction nozzle body is arranged in the suction nozzle inner cavity; and the tongue plate can swing when the sweeper works so that the cross-sectional flow area of the suction inner cavity is increased or reduced. By optimizing the flow field, the suction nozzle disclosed by the invention can guarantee relatively good adaptability of the road sweeper to dense garbage and light garbage on the ground, so that the adaptability of the road sweeper to the road garbage is enhanced, and the sweeping quality and working efficiency of the road sweeper are improved.

Owner:HUNAN UNIV

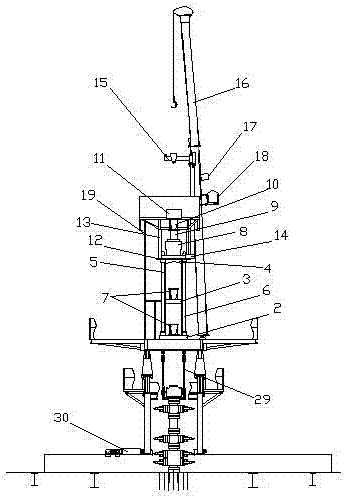

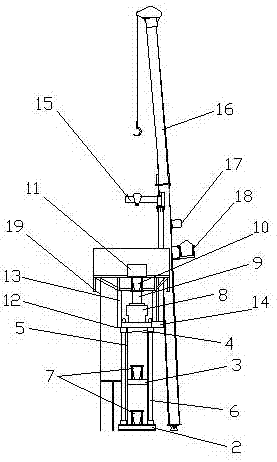

Multi-oil-cylinder lifting and rotation integrated type ocean hydraulic workover rig

ActiveCN107218000AImprove the efficiency of rotary operationsEasy to operateDrilling rodsDrilling casingsCantileverWorkover

The invention provides a multi-oil-cylinder lifting and rotation integrated type ocean hydraulic workover rig. According to the workover rig, a sliding base module is installed on a guide tube frame platform, a blowout preventer unit is installed in the middle of a lower sliding base of the sliding base module, a vertical platform, a hydraulic power mechanism and a lifting module are installed on an upper sliding base of the sliding base module, an operation platform is installed on the upper portion of the lifting module, a tong rotating arm is connected with an installation support and the operation platform, a telescopic pull rod is connected with the upper sliding base and the operation platform, and the hydraulic power mechanism is connected with a main operation table, an auxiliary operation table and a blowout preventer driller console through pipelines and wires, wherein the main operation table, the auxiliary operation table and the blowout preventer driller console are on the operation platform. The multi-oil-cylinder lifting and rotation integrated type ocean hydraulic workover rig is suitable for the ocean engineering well workover and completion operation field, and with cooperation of a supporting platform, the multi-oil-cylinder lifting and rotation integrated type ocean hydraulic workover rig can provide underground operation services for production platform oil and gas wells under the circumstance that an ocean production platform is not provided with a workover rig module or after a supporting platform is in place, a rear cantilever beam is limited in travel and cannot cover an operating well set.

Owner:中石化四机石油机械有限公司 +1

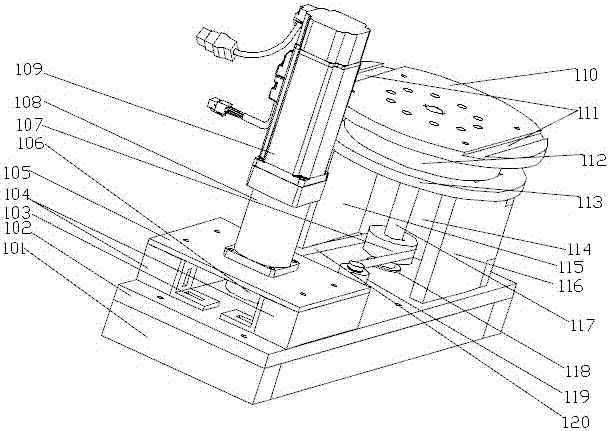

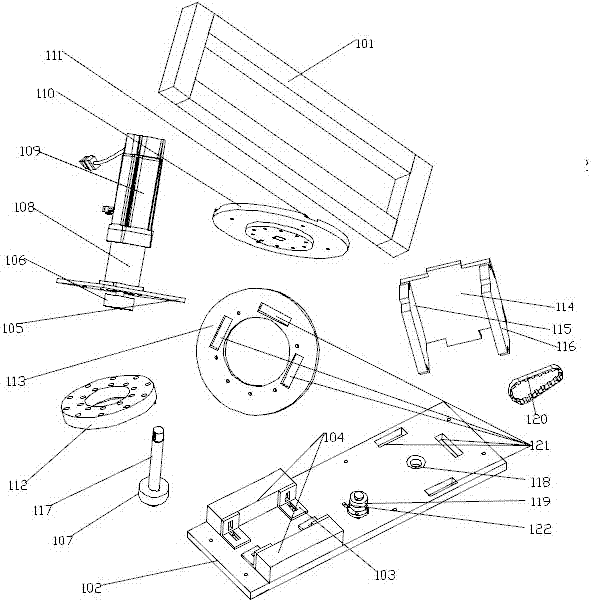

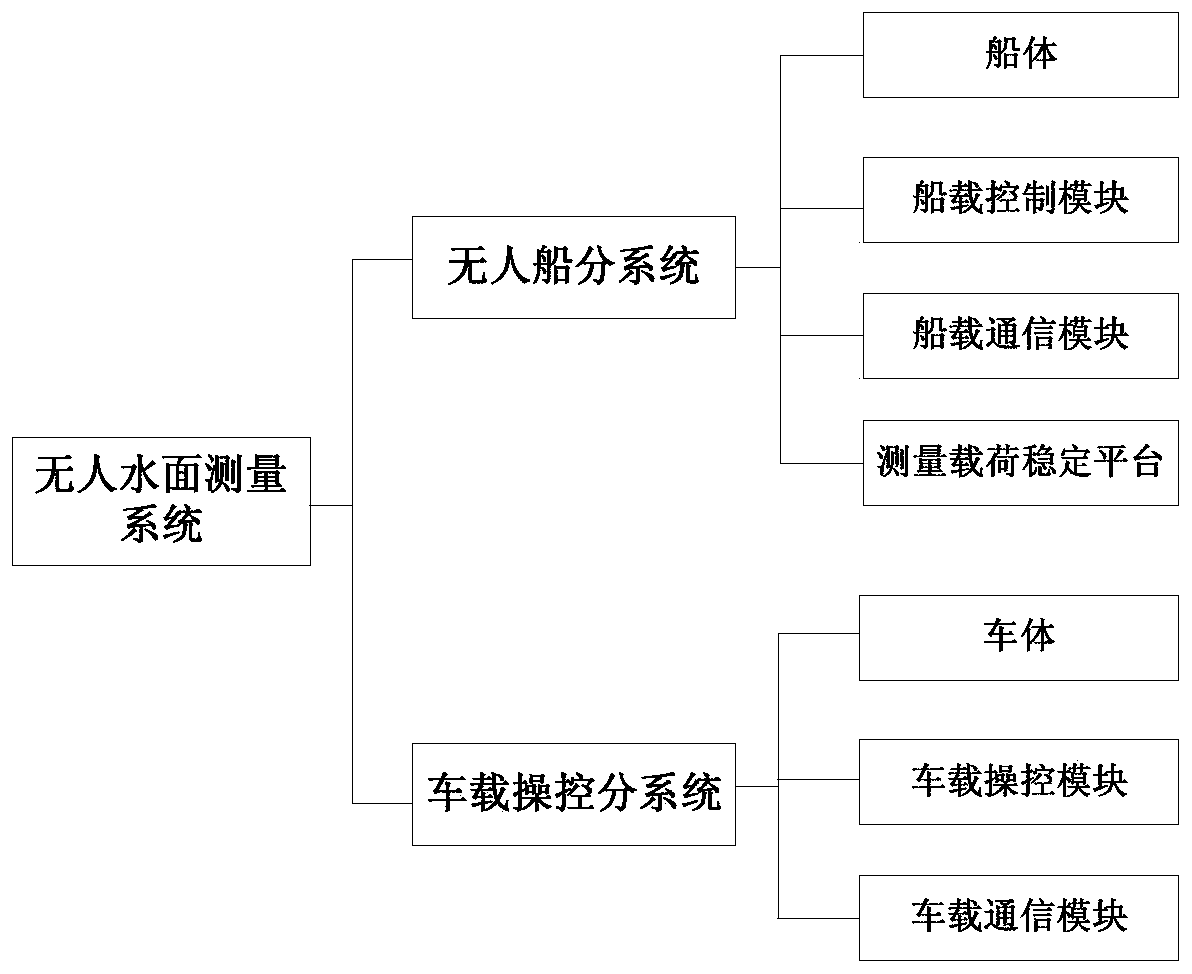

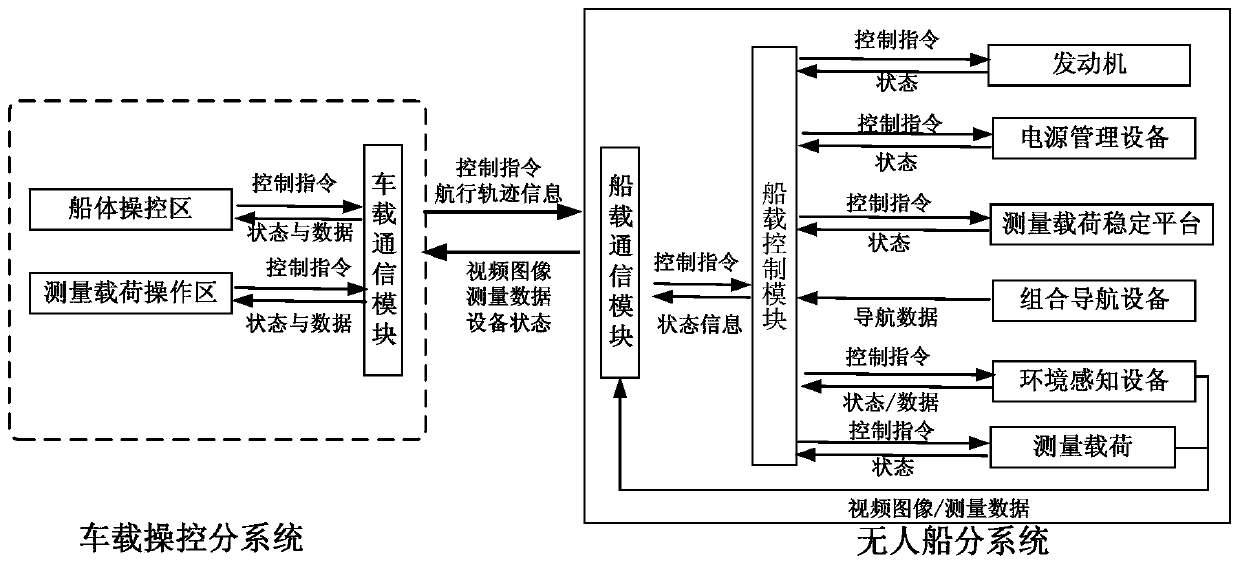

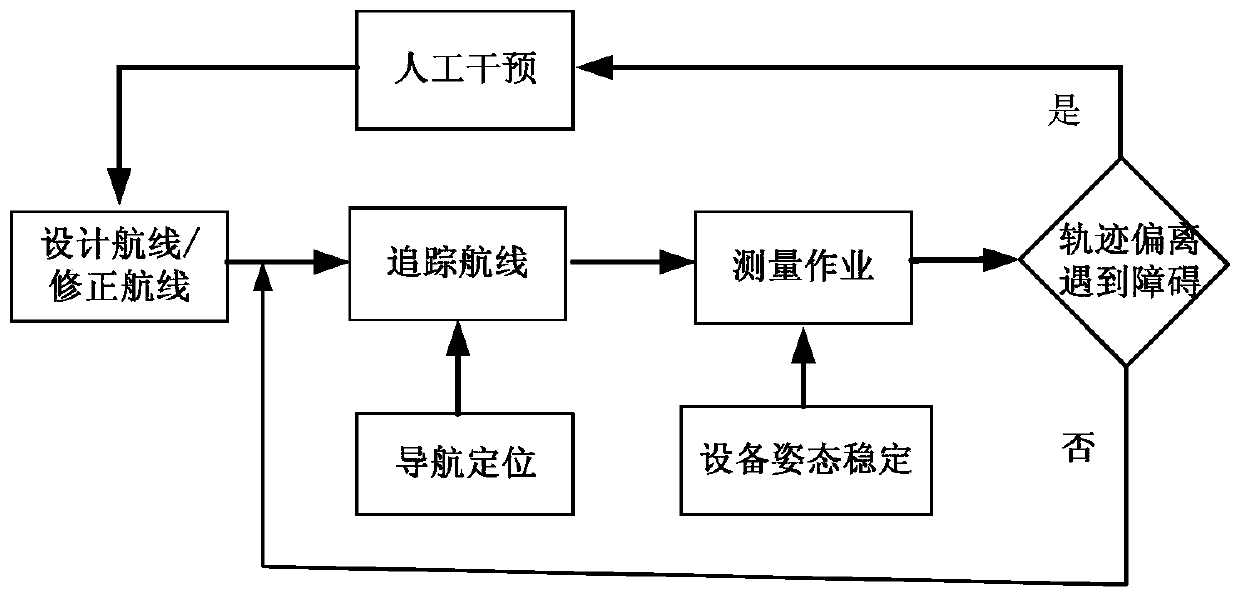

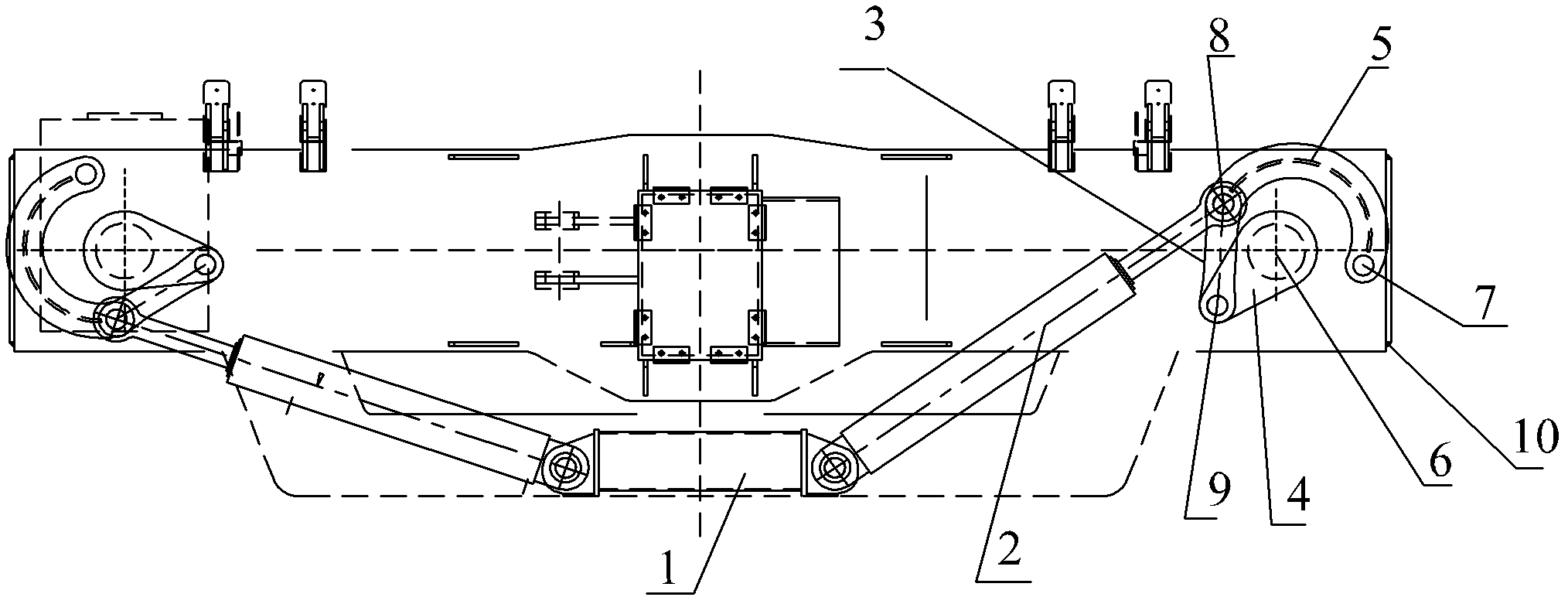

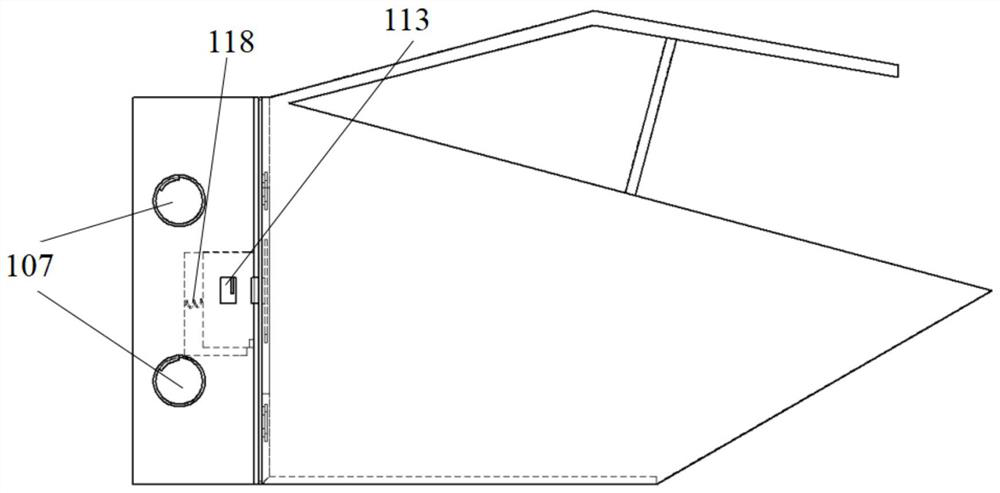

Unmanned surface measuring system with measuring load stabilized platform

InactiveCN110834698ALittle change in postureMeasuring load attitude stabilityMeasurement devicesUnmanned surface vesselsIn vehicleRemote control

The invention relates to an unmanned surface measuring system with a measuring load stabilized platform. The system comprises an unmanned ship subsystem and a vehicle-mounted operation subsystem. Theunmanned ship subsystem sends ship and measuring load state data and measuring data to the vehicle-mounted operation subsystem, the vehicle-mounted operation subsystem receives and processes the shipand measuring load state data and the measuring data and is used for carrying out remote control over the unmanned ship subsystem, the unmanned ship subsystem comprises a ship body, a ship-mounted control module, a ship-mounted communication module and a measuring load stabilizing platform, and the vehicle-mounted control subsystem comprises a vehicle body, a vehicle-mounted operation module and avehicle-mounted communication module. A three-body type ship model is adopted in the ship body, the posture change amplitude is small, the good work condition is provided for measuring load gesture stability preliminarily, the measuring load stabilized platform is adopted for mounting measuring loads, measuring load gesture stability is kept, and the measuring load measuring effect can be obviously improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

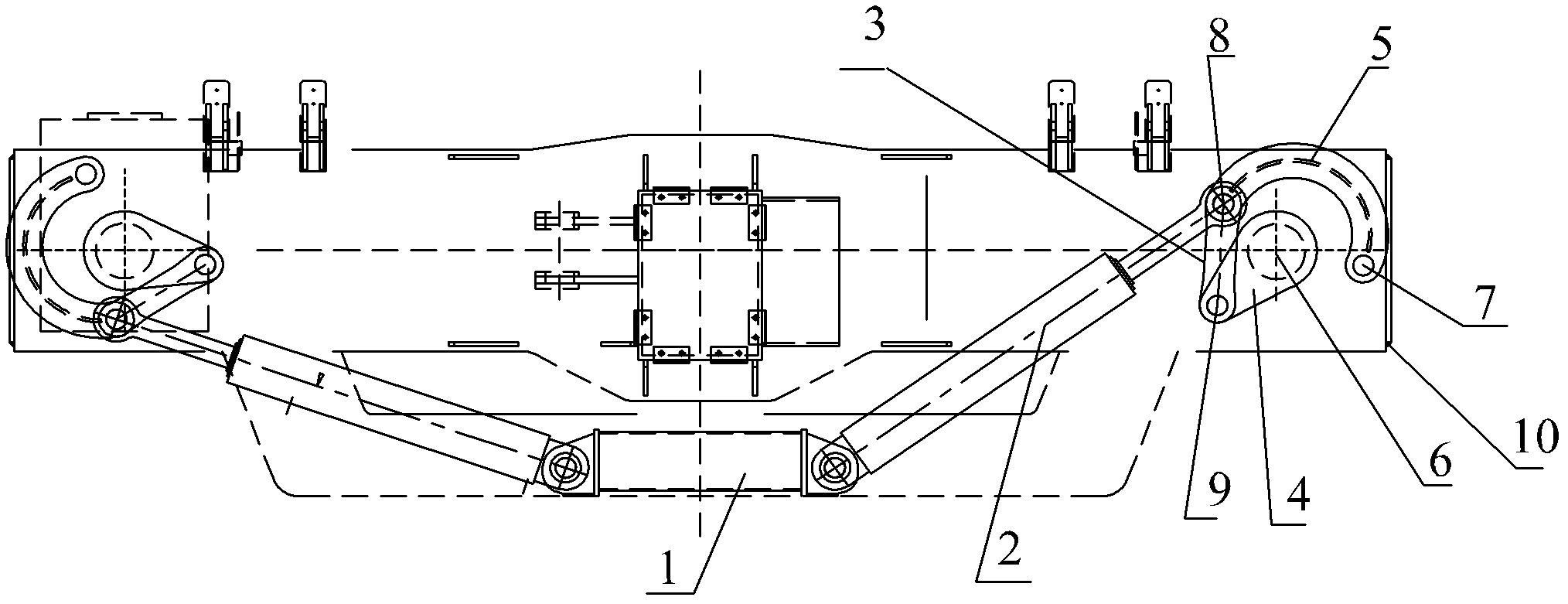

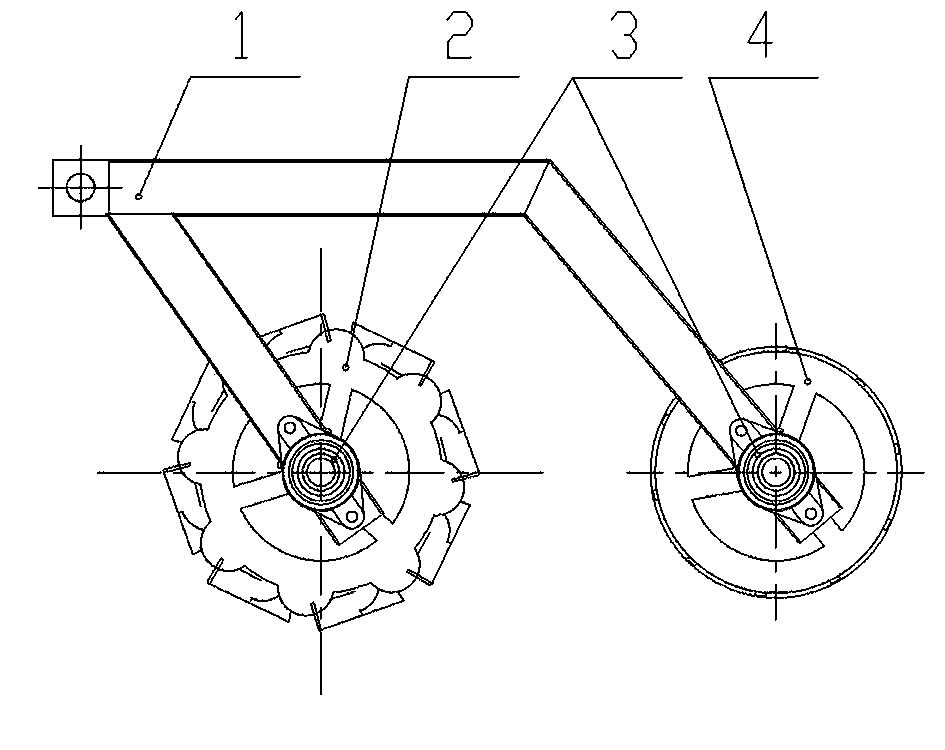

Four-connecting-rod steering device

InactiveCN102490786AImprove job adaptabilityMeet steering needsSteering linkagesHydraulic steering gearsHydraulic cylinderVehicle frame

The invention discloses a four-connecting-rod steering device and aims at providing the four-connecting-rod steering device capable of realizing the 0 to 180-degree steering to realize various steering modes of vehicles and to adapt to small-field operation requirements. The four-connecting-rod steering device comprises a steering hydraulic cylinder, an arc-shaped steering arm, a rotating shaft, a rotary support arm, a steering shaft and a push rod, wherein the steering hydraulic cylinder is hinged with a hydraulic cylinder seat, a piston rod of the steering hydraulic cylinder, one end of the arc-shaped steering arm and one end of the push rod are hinged at one point, the other end of the arc-shaped steering arm is hinged with a vehicle frame through the rotating shaft, the other end of the push rod is hinged with the rotary support arm, the rotary support arm is connected with the steering shaft, the steering shaft is fixedly connected with a wheel support frame, and steering wheels are arranged on the wheel support frame. The steering device can ensure that wheels can realize the 0 to 180-degree steering, so the steering requirements in various steering modes of the vehicles can be met, and the operation adaptability in narrow and small fields is high.

Owner:MILITARY TRANSPORTATION UNIV PLA

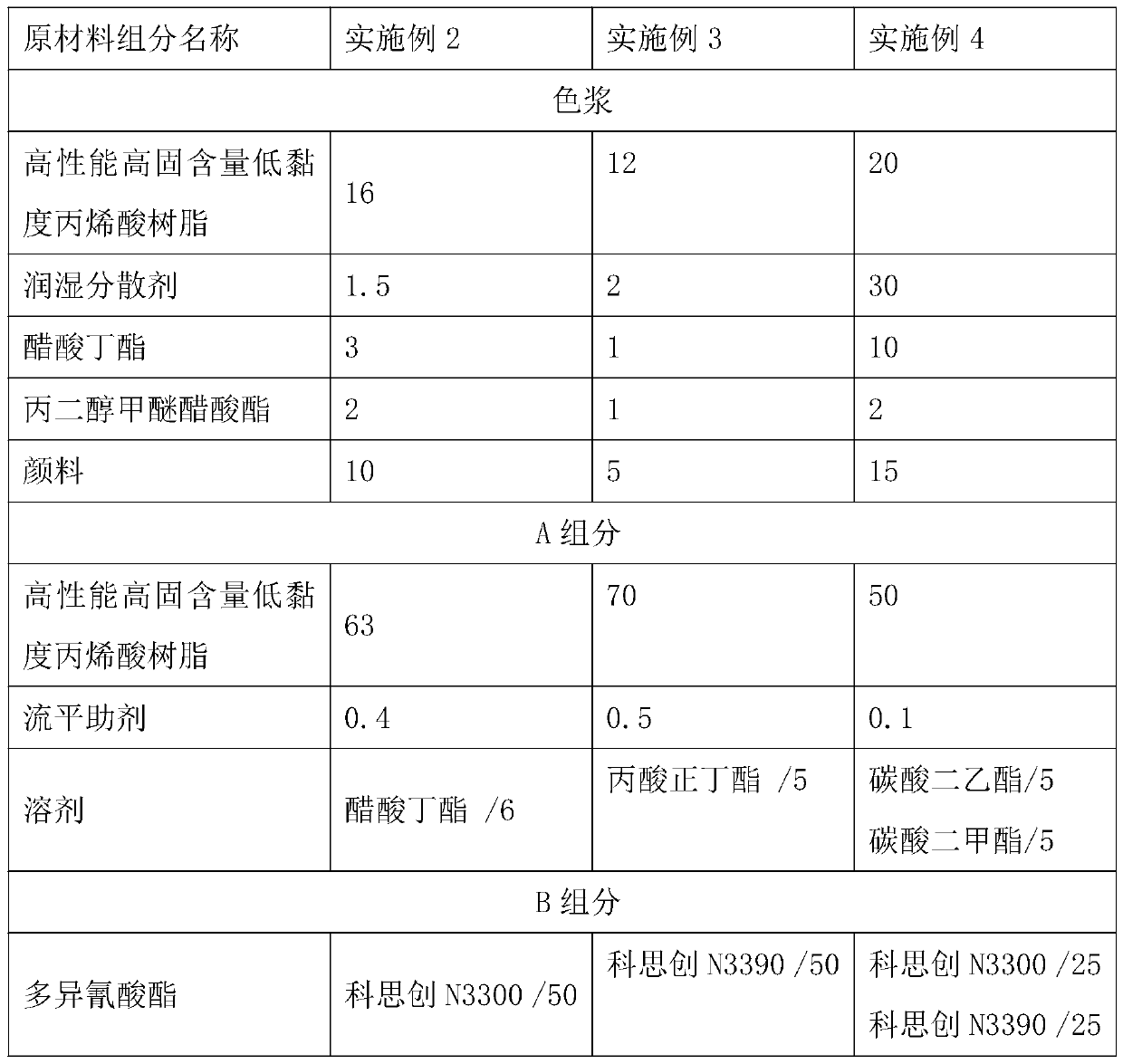

Preparation method and application of high-performance high-solid-content low-viscosity acrylic resin

The invention discloses a preparation method of high-performance high-solid-content low-viscosity acrylic resin. The method comprises the following steps: preparation of a dropwise-adding material: adding 10-20 parts of a cycloalkyl methacrylate monomer, 15-30 parts of non-functional acrylate, 8-10 parts of a hydroxyl-containing (methyl)acrylate or a derivative thereof, 0.5-2 parts of methacrylicacid, 8-15 parts of a vinyl monomer and 0.3-0.6 part of an initiator into a head tank, and carrying out uniform mixing under stirring; preparation of a stirring material: adding 5-35 parts of an estersolvent and 10-20 parts of propylene glycol ether and ether ester into a reaction kettle provided with stirring paddles, a thermometer and a condenser, and carrying out heating to 90-110 DEG C; and dropwise addition of the dropwise-adding material into the reaction kettle, heat preservation for 3-5 hours, cooling, filtering, and discharging to obtain the resin. The invention also discloses an environment-friendly automobile coating prepared from the resin. A preparation method for the automobile coating comprises the following steps: (1) preparing a component A, namely preparing color paste and the component A; (2) preparing a component B; and (3) uniformly mixing the two components according to a ratio of 2: 1 to obtain the environment-friendly automobile coating. The coating is high insolid content and good in comprehensive performance.

Owner:QINGYUAN HAOYU CHEM TECH

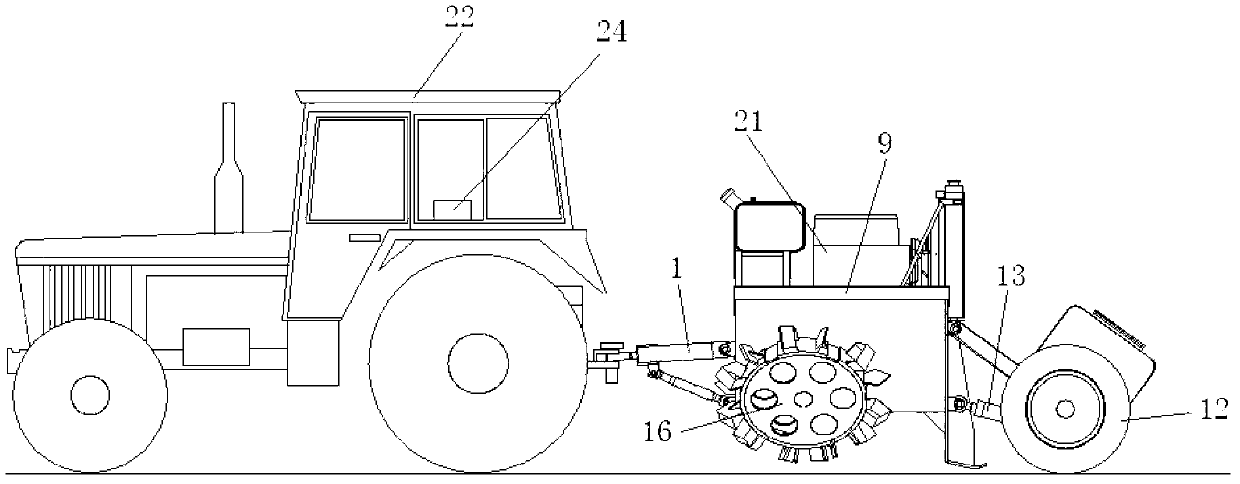

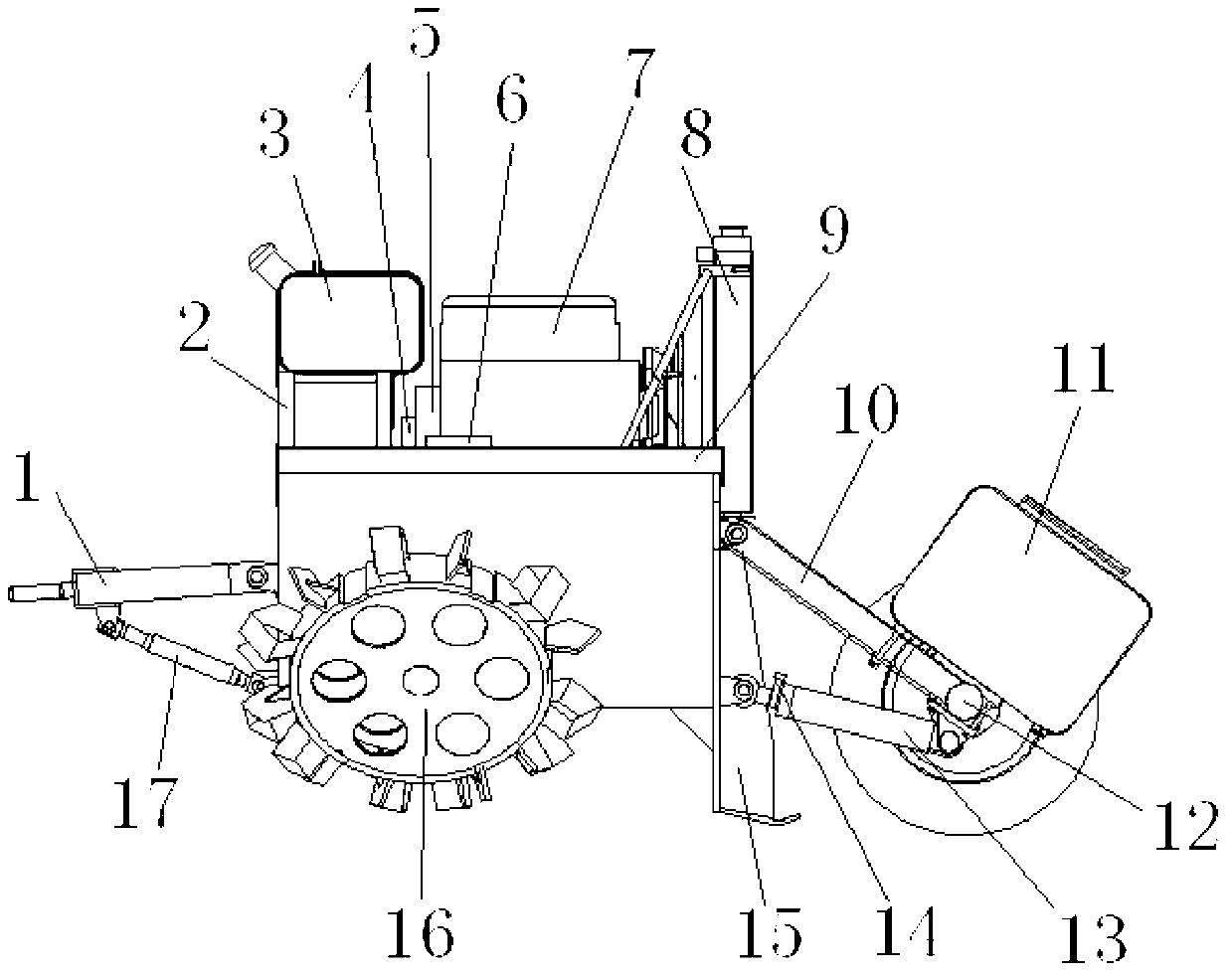

Farmland ditcher and controlling method thereof

ActiveCN103276760AImprove job adaptabilityReduce power consumptionSoil-shifting machines/dredgersAutomatic controlFarm machine

The invention relates to the field of agricultural machines, in particular to a farmland ditcher. The farmland ditcher comprises a rack, a ditching cutter head, a supporting device, a driving device and a controller. The ditching cutter head and the supporting device are respectively arranged on the rack, and the driving device is connected with a revolving shaft of the ditching cutter head. The controller controls the driving device to respectively drive the ditching cutter head to perform ditching work and drive the supporting device to perform lifting movement, and the driving device is an independent hydraulic system. According to the farmland ditcher, the driving device is utilized to drive the ditching cutter head to rotate and drive the supporting device to perform lifting movement so as to adjust the height of the rack, and therefore the depth adjustment of the ditching work is performed. The hydraulic driving type working principle is utilized, power of the ditching work is provided through the independent hydraulic system, automatic control of the rotating speed of the ditching cutter head and lifting of the supporting device of the farmland ditcher is performed with a controlling method of the farmland ditcher, real-time adjustment of the rotating speed of the ditcher cutter head and the depth of the ditching work is achieved, and work adaptability of the farmland ditcher to different soil conditions is improved.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

Transfer robot end effector comprising electromechanical servo system

The invention relates to a transfer robot end effector comprising an electromechanical servo system. The end effector comprises a connector assembly, a clamping jaw device and a servo transmission device, wherein the servo transmission device comprises a left-and-right clamping jaw servo motor, a front-and-back clamping jaw servo motor, a transmission gear and the like. In actual work, the two servo motors of the servo transmission device drive clamping jaws to move after primary gear transmission, and left-and-right and front-and-back clamping jaws perform grabbing or stacking actions simultaneously. The end effector has the advantages that the product reliability is high, the running speed can be accurately controlled, the load range is wide, the working efficiency is high, the end effector is applicable to any space and environments such as plateau regions, extremely cold regions, extremely hot regions and the like, and the like.

Owner:XIAN SILVER HORSE IND DEV CO LTDRIAL DEV CO LTD

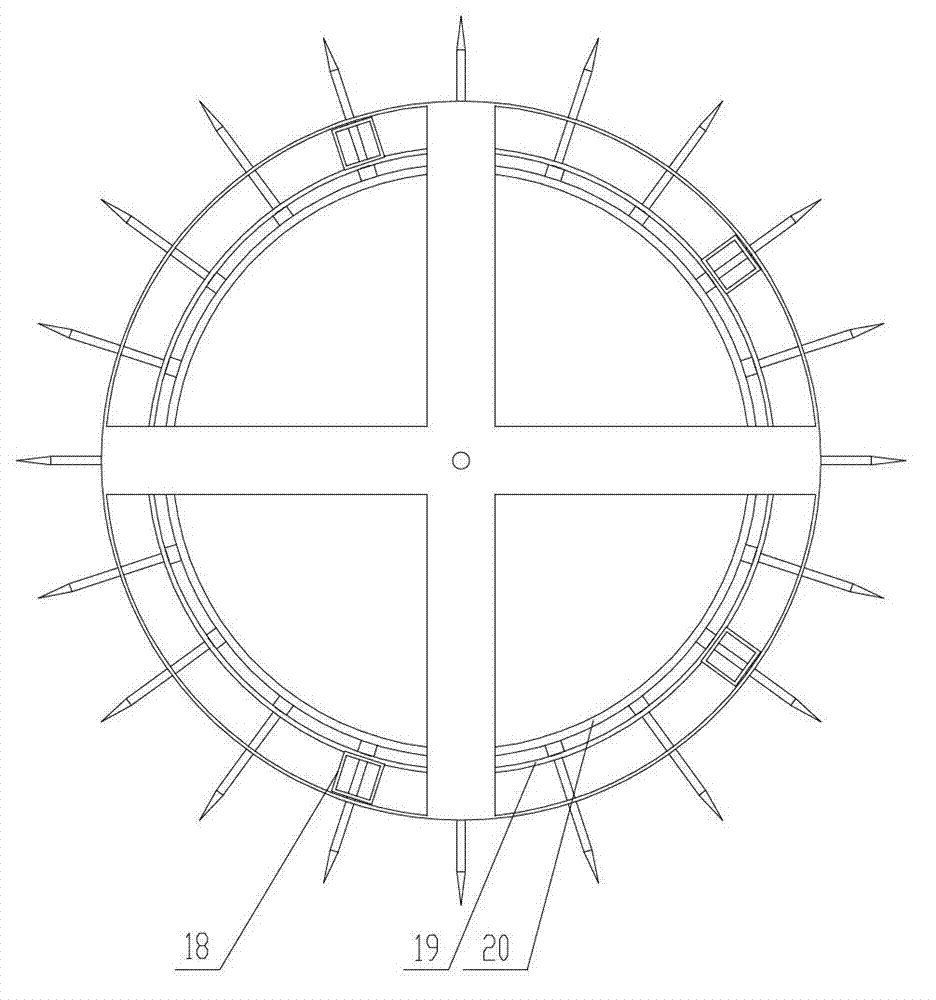

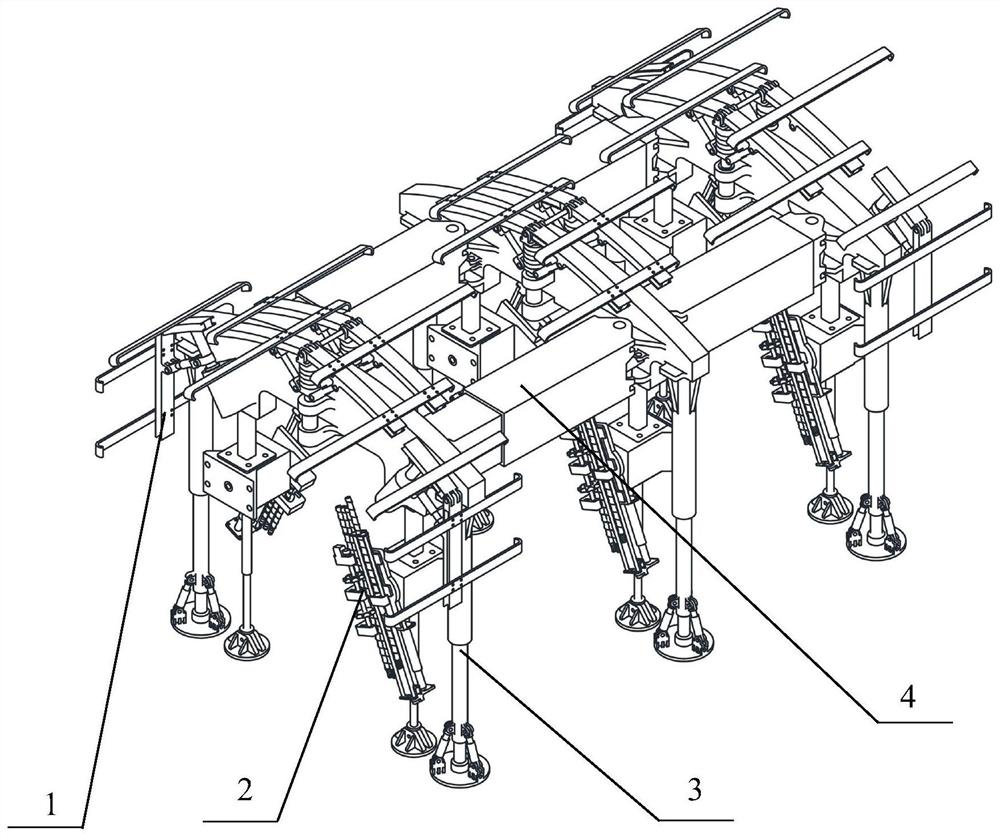

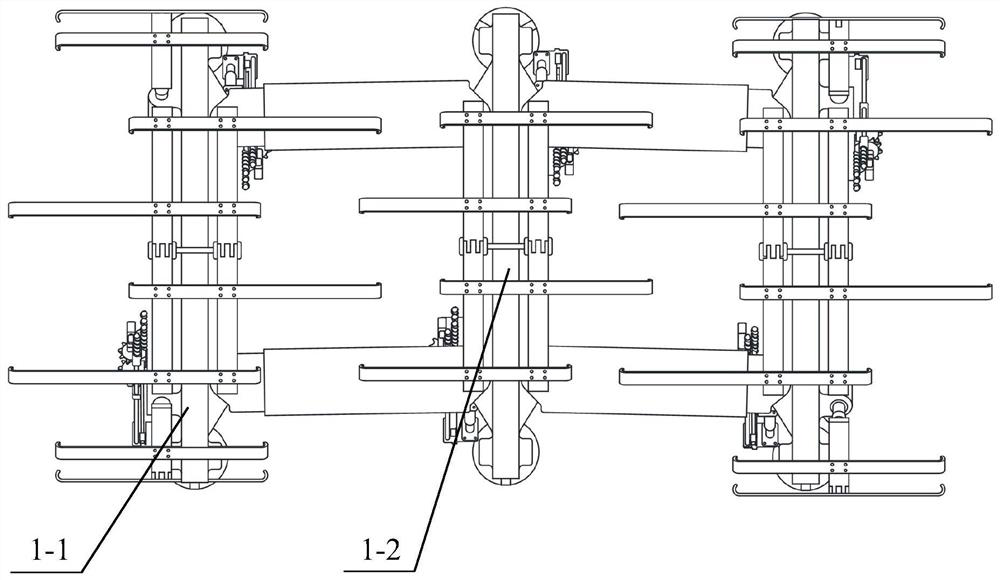

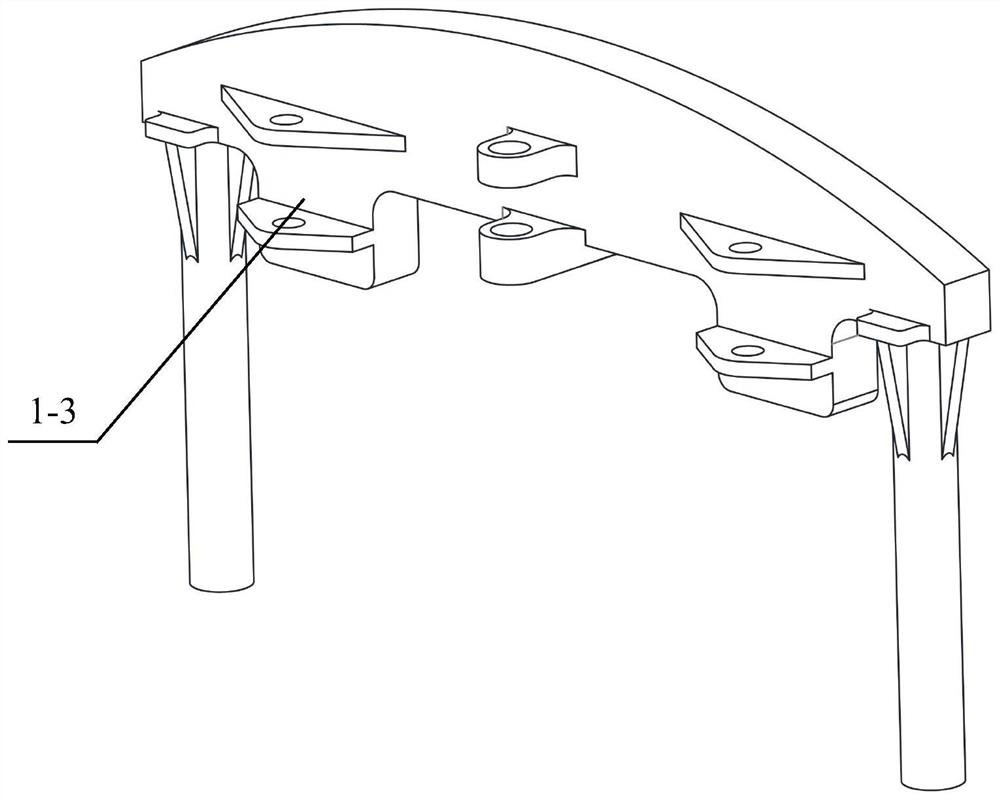

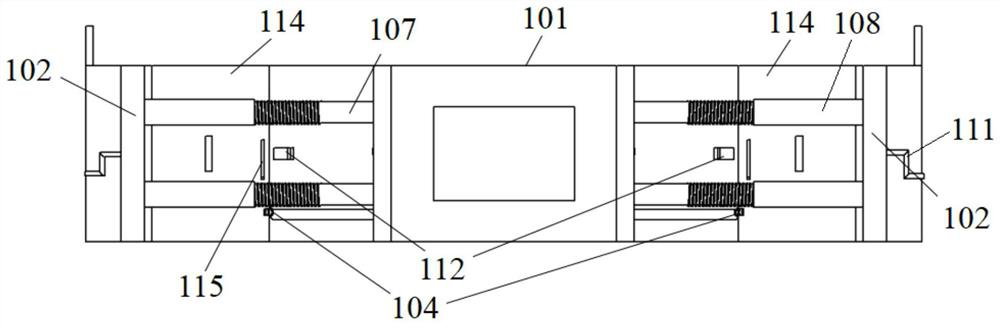

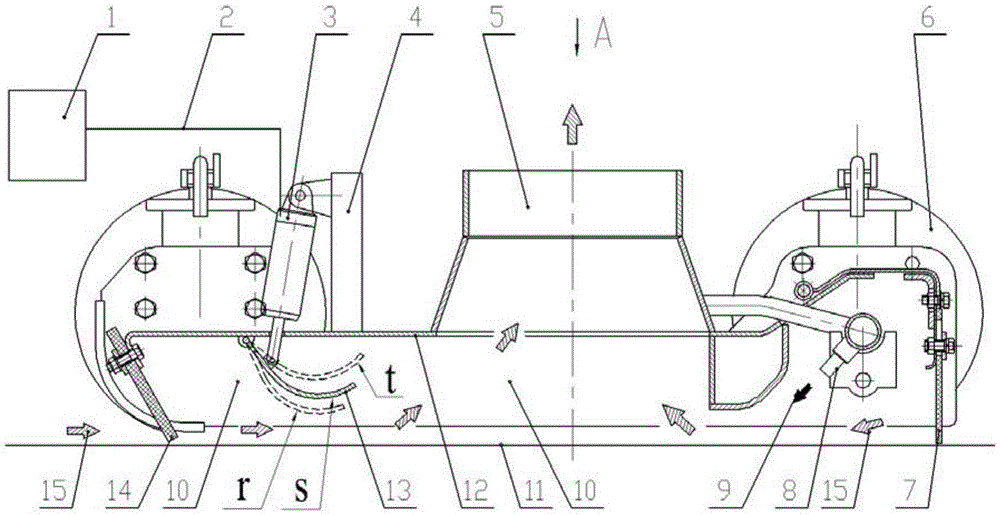

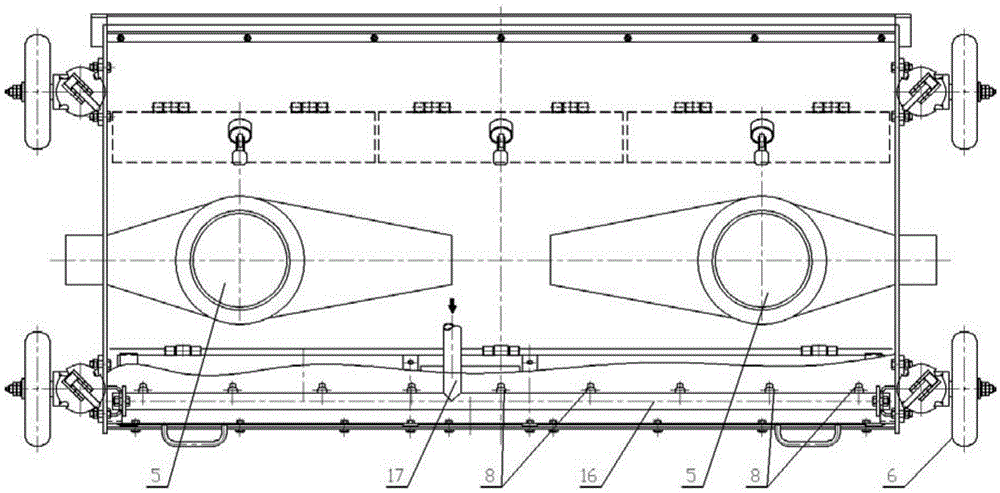

Step-type anchoring robot of fully mechanized excavation face

PendingCN111608705ASimple structureSmooth goingDrilling rodsUnderground chambersSupporting systemControl engineering

The invention discloses an anchoring intelligent device, belongs to the field of fully mechanized excavation face mechanical and electrical equipment and comprises four parts including a net struttingsystem, an anchoring system, a ground supporting system and a power and turning system, wherein the net strutting system is installed above the ground supporting system; the anchoring system is installed by screws under a main beam and a middle main bear inside the net strutting system; the ground supporting system is installed under the middle beam and the middle main beam inside the net strutting system and provides support for the whole device; and through pin connection, two ends of the power and turning system are connected to the main beam and the middle main beam inside the net strutting system respectively. Further, the robot disclosed by the invention is small in size and compact in structure, has functions of realizing multi-anchor-rod coordinated operations and auxiliary pavement of an anchor net and has high anchoring efficiency; and the device adopts a step-type advancing mode, so that running is steady, turning is flexible and maneuvering performance is good.

Owner:ANHUI UNIV OF SCI & TECH

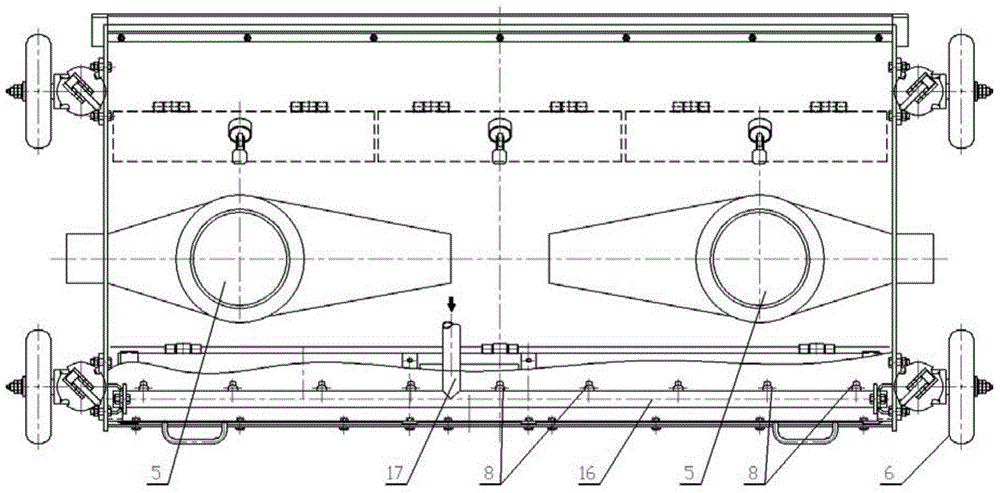

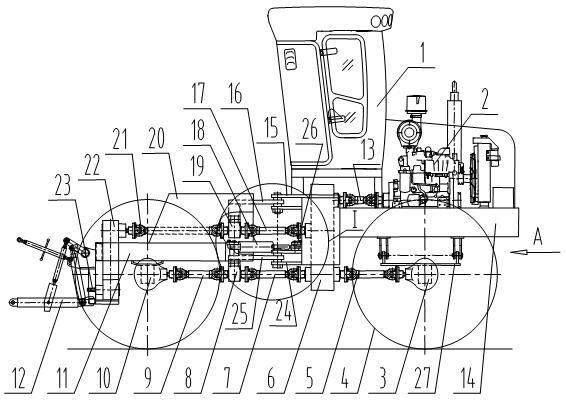

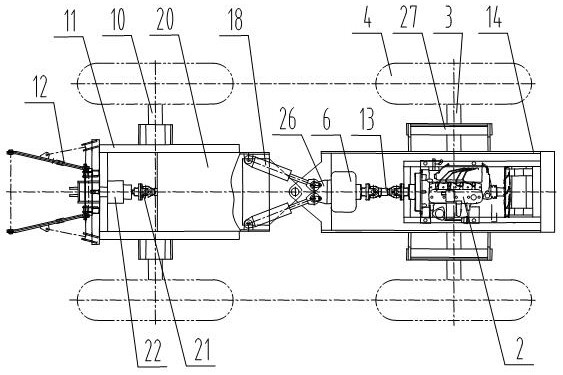

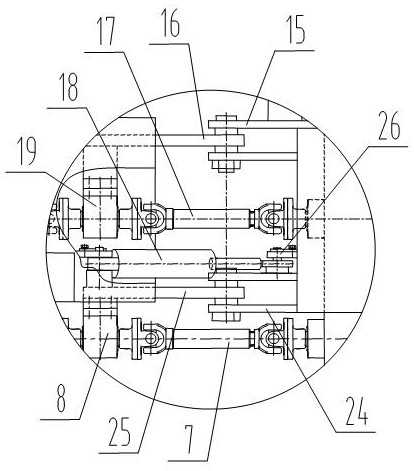

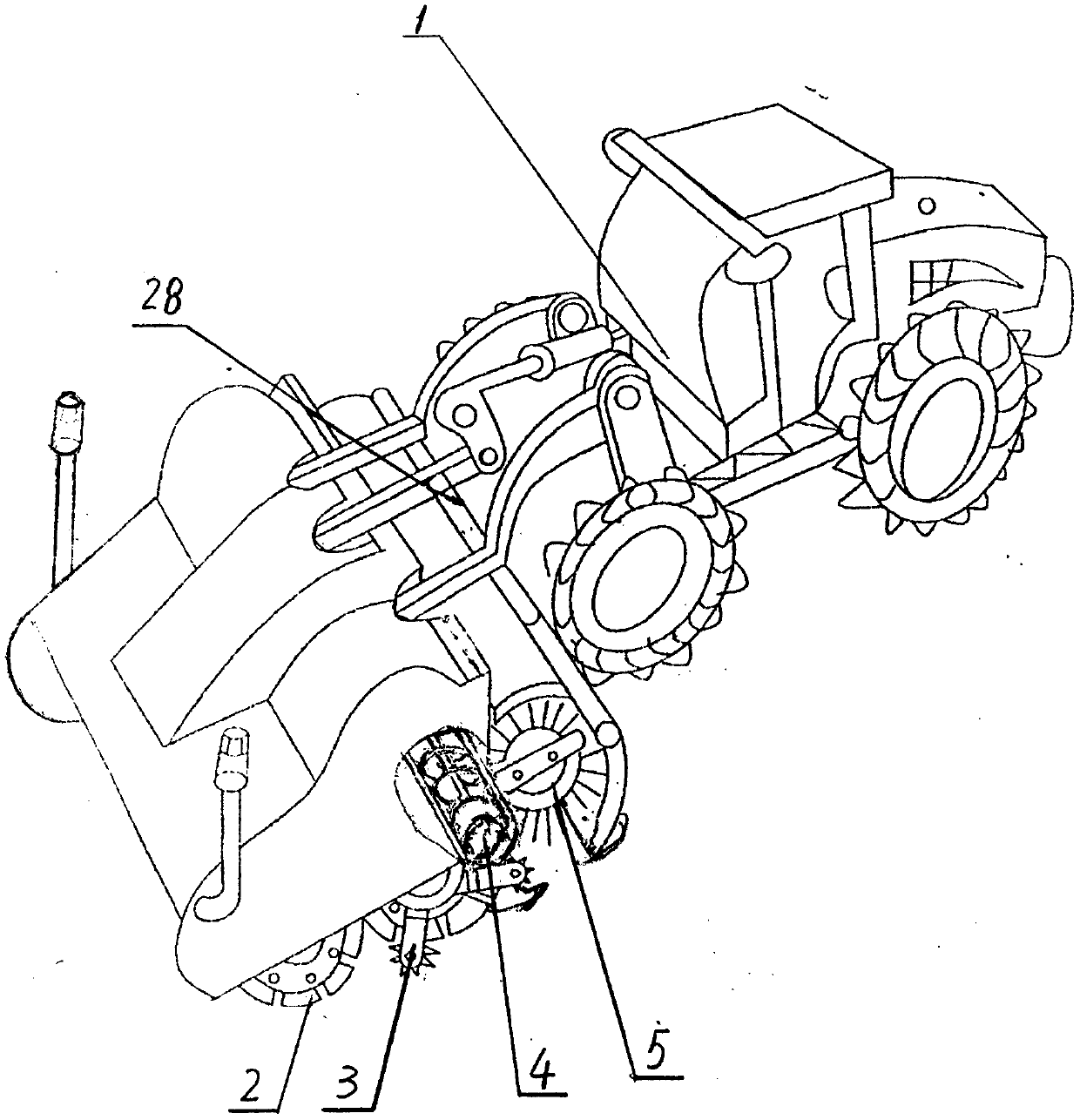

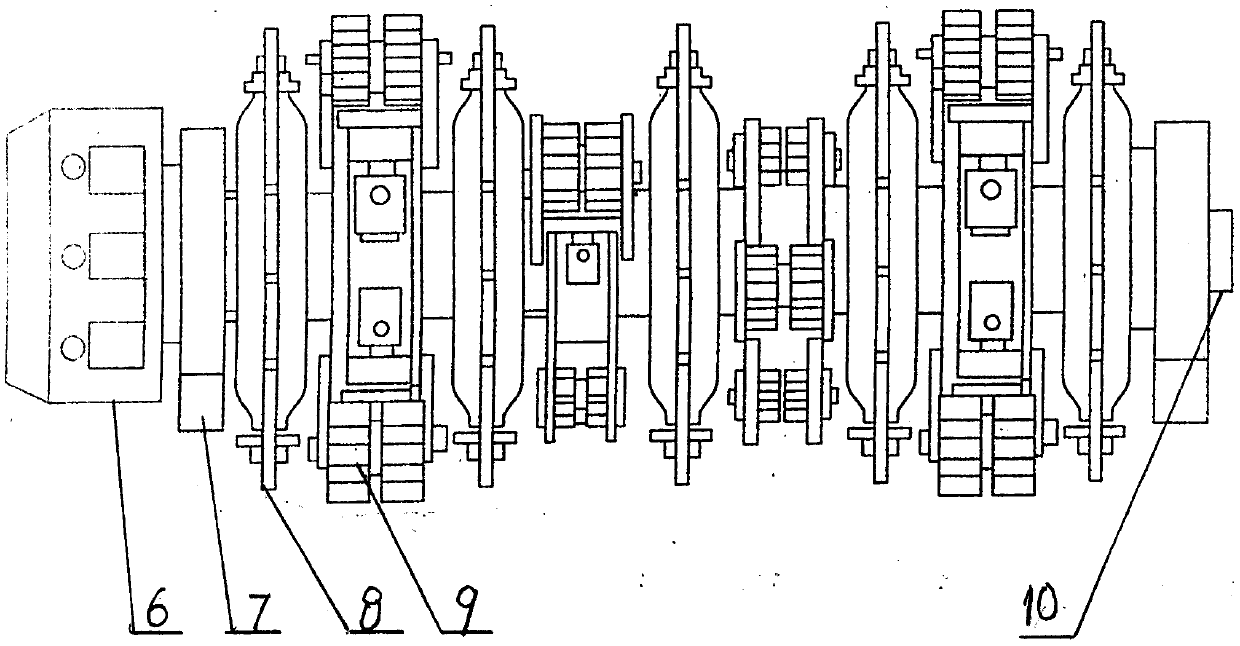

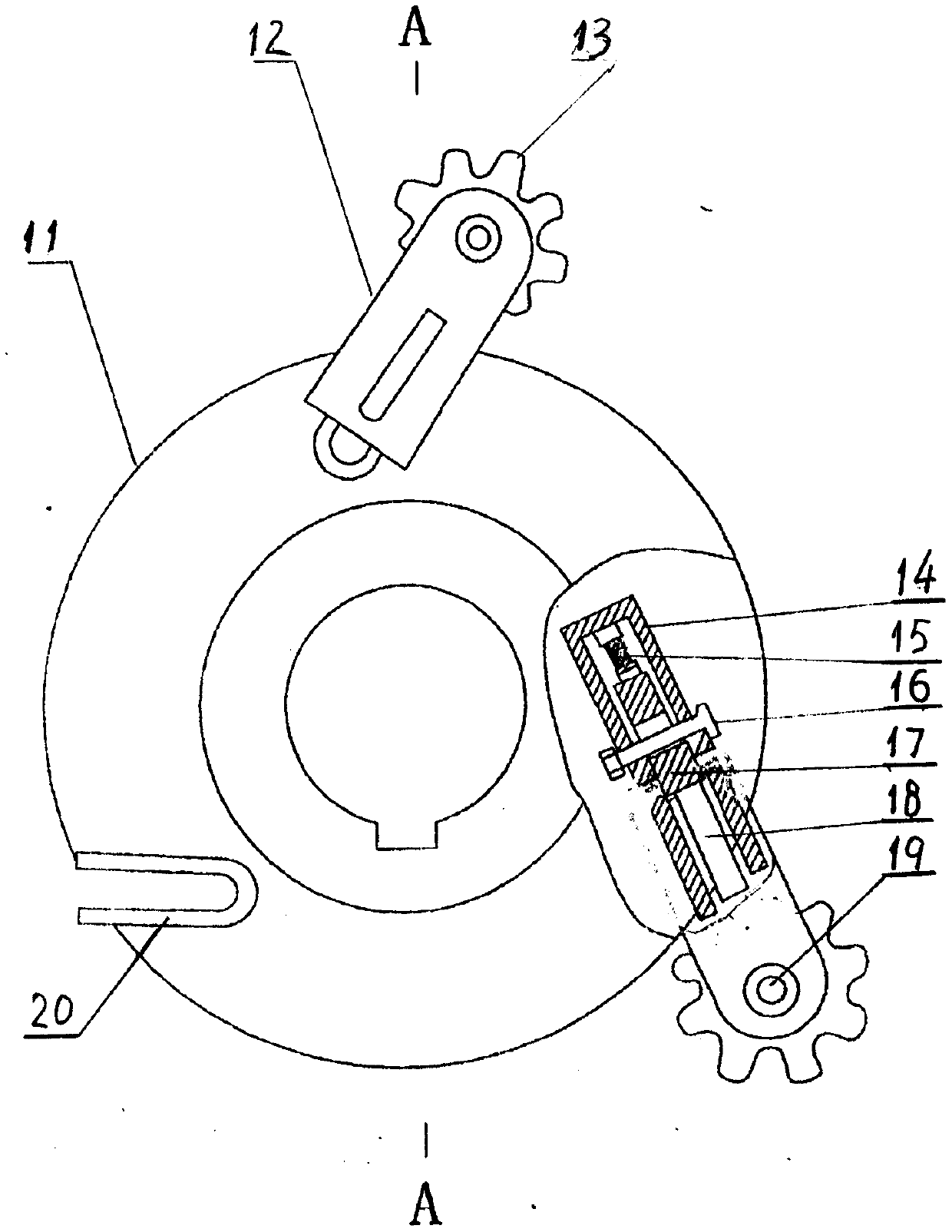

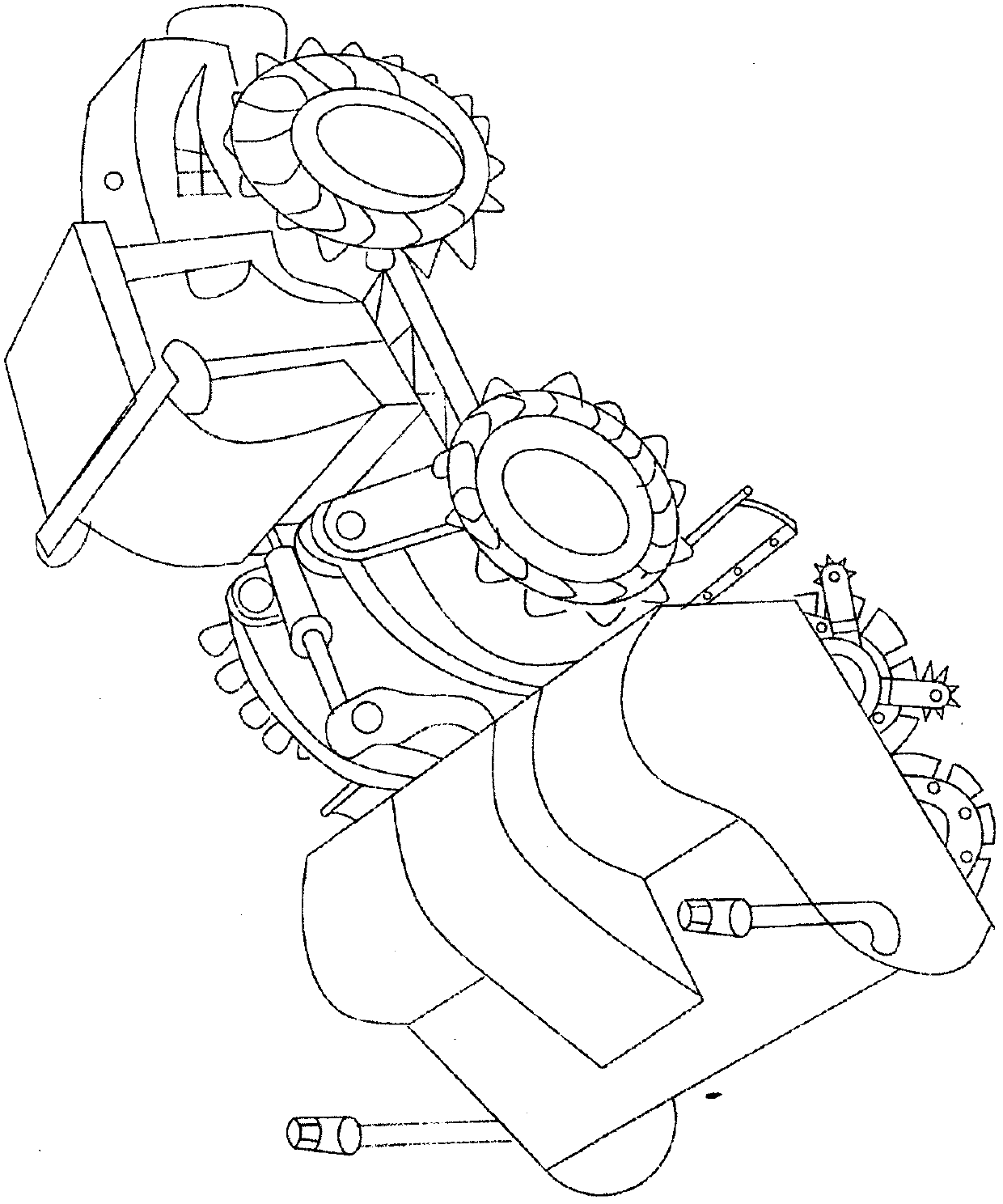

Hinge steering four-wheel drive tractor

PendingCN111891218AGive full play to tractionImprove job adaptabilityAuxillary drivesTractorsDrive wheelAgricultural engineering

The invention discloses a hinge steering four-wheel-drive tractor, and aims to provide a hinge steering four-wheel drive tractor which is high in operation adaptability, good in adhesiveness and highin driving force. A transverse profiling frame is arranged below the front frame body; the transverse profiling frame is fixedly arranged on the front axle; driving wheels are mounted at two ends of the front axle in a rolling manner; a rear frame box body is arranged on the rear frame body; the rear frame body is fixedly arranged on the rear axle; driving wheels are mounted at two ends of the rear axle in a rolling manner; a hinge steering mechanism is arranged between the front frame body and the rear frame box body; the central transmission case is arranged below the cab and fixedly arranged on the front frame body, the four-wheel drive transmission system is respectively connected with the central transmission case, the front axle and the rear axle, the power output system is connectedwith the central transmission case, and the hydraulic suspension mechanism is arranged at the rear end of the rear frame body. The invention is suitable for paddy-upland field agricultural machinerypower.

Owner:虎林市振达农业机械制造有限公司

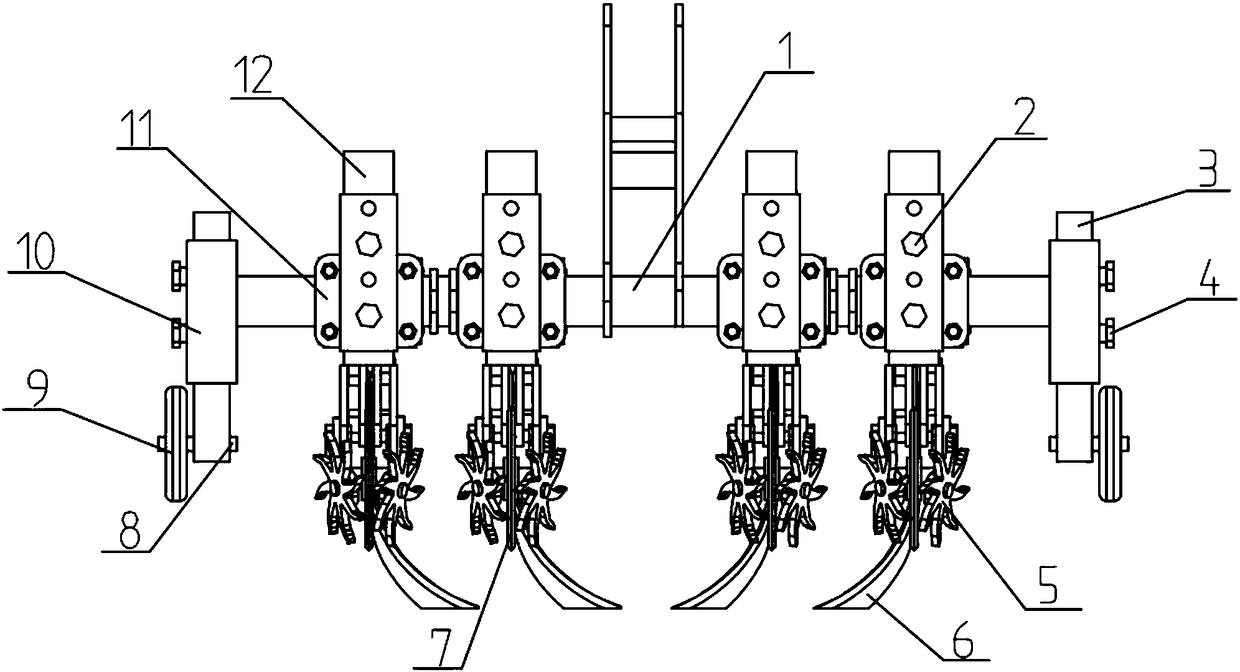

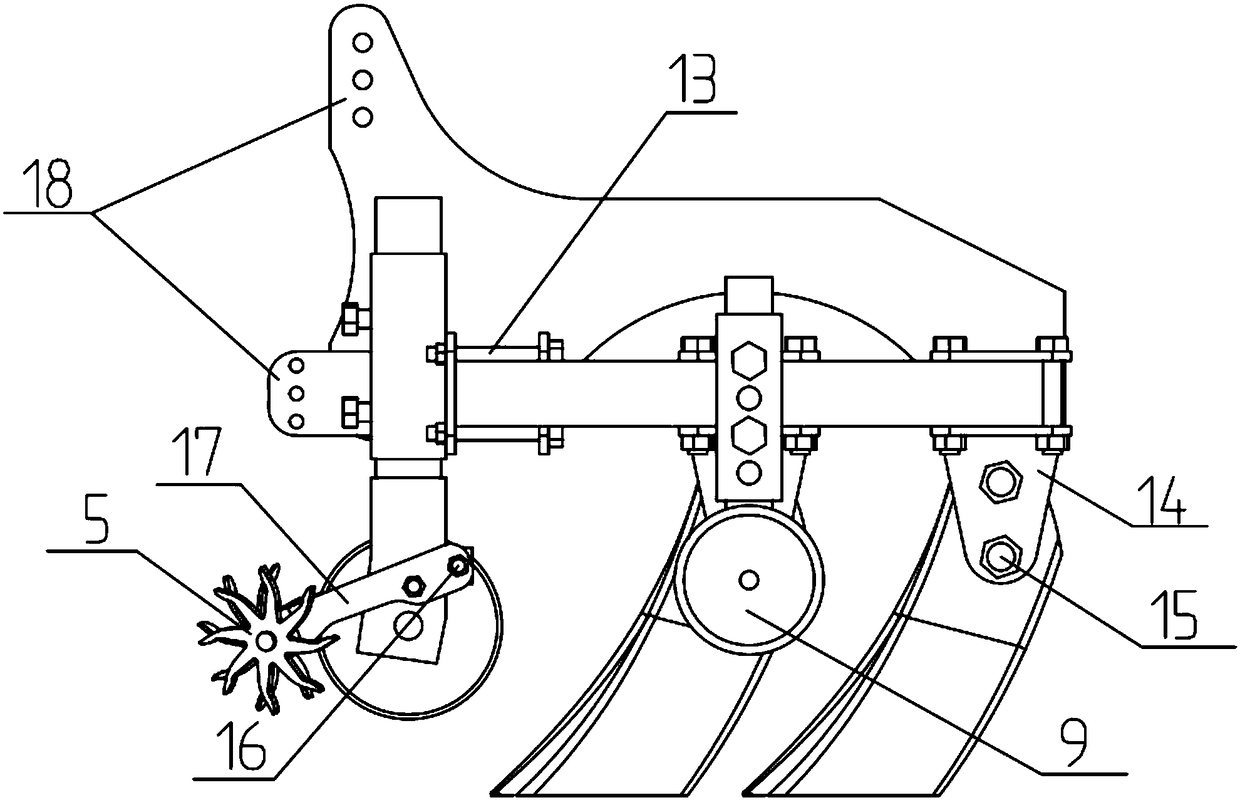

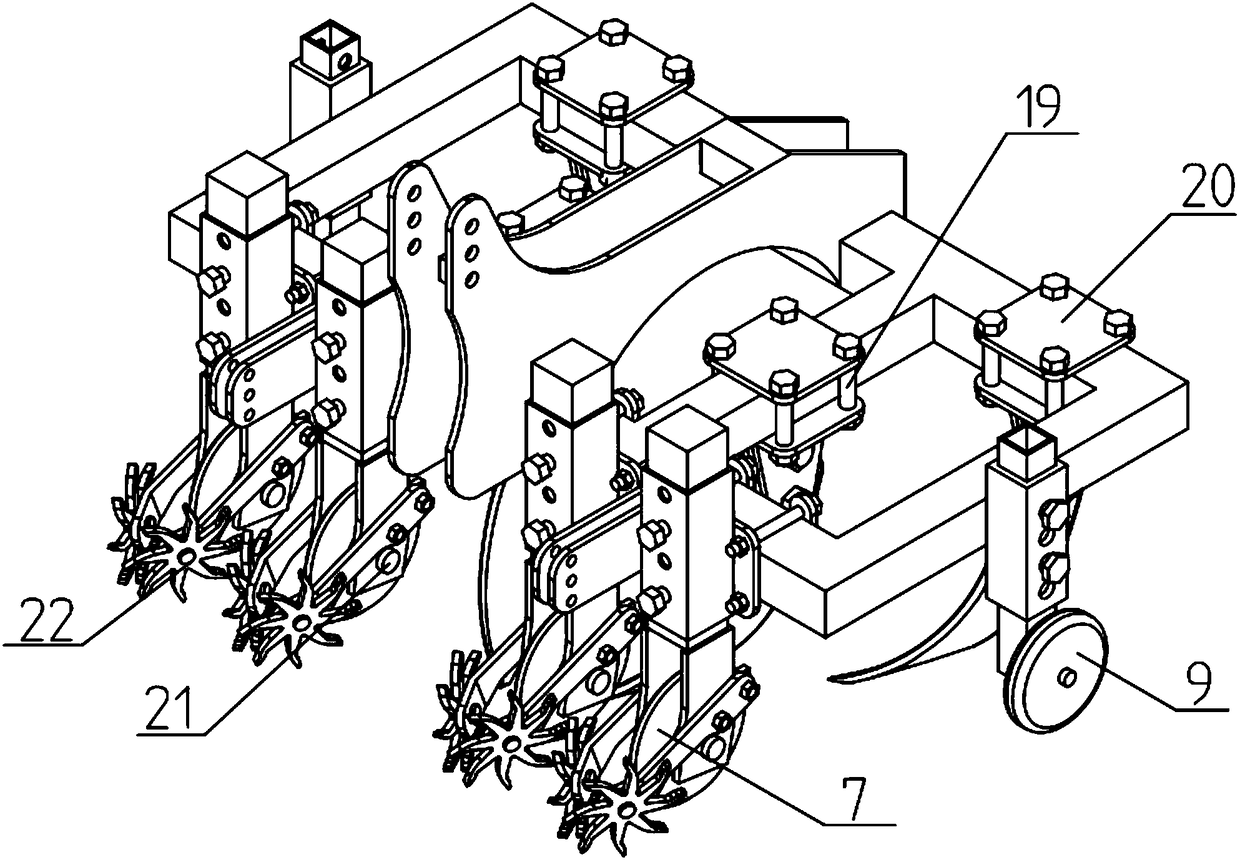

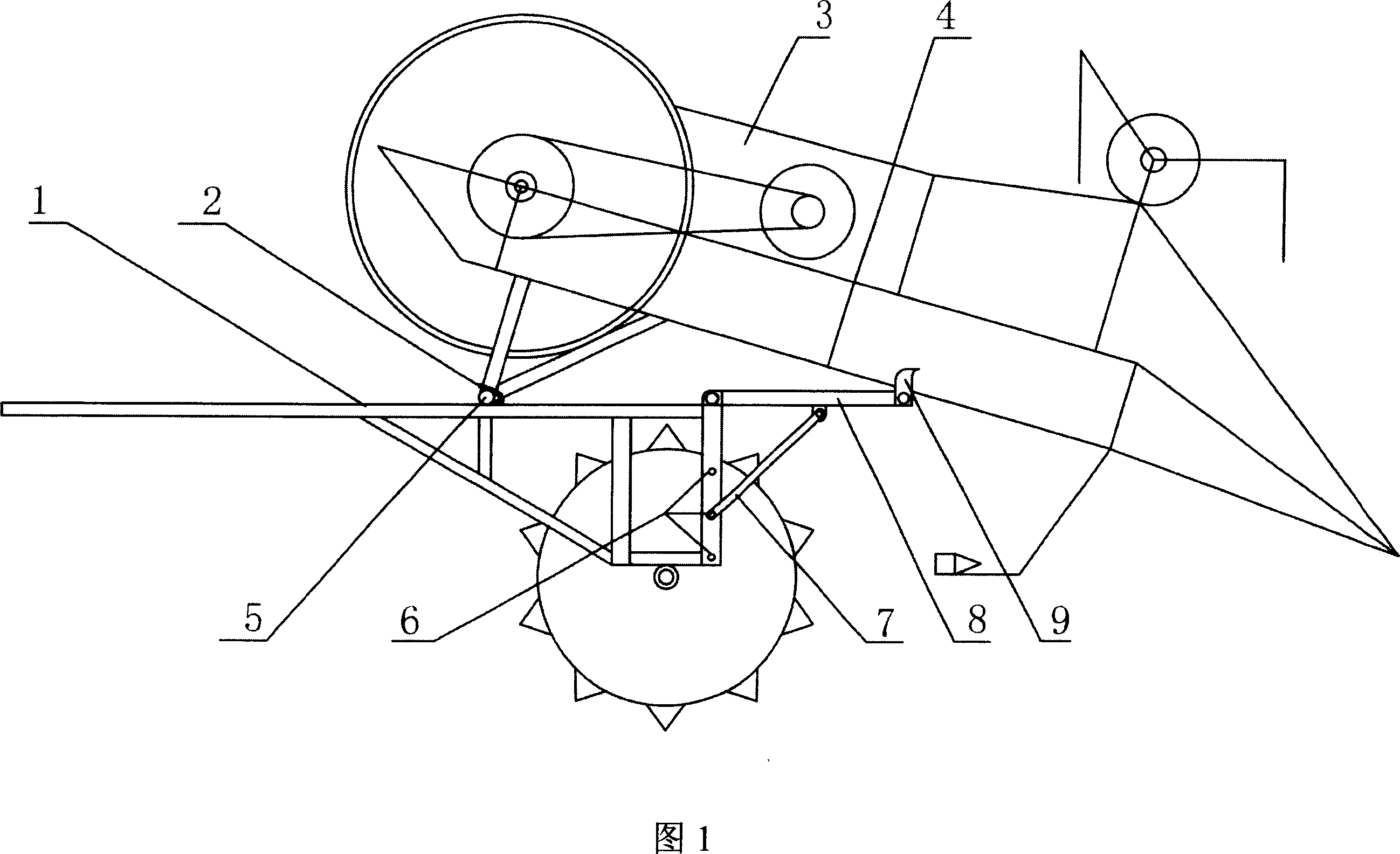

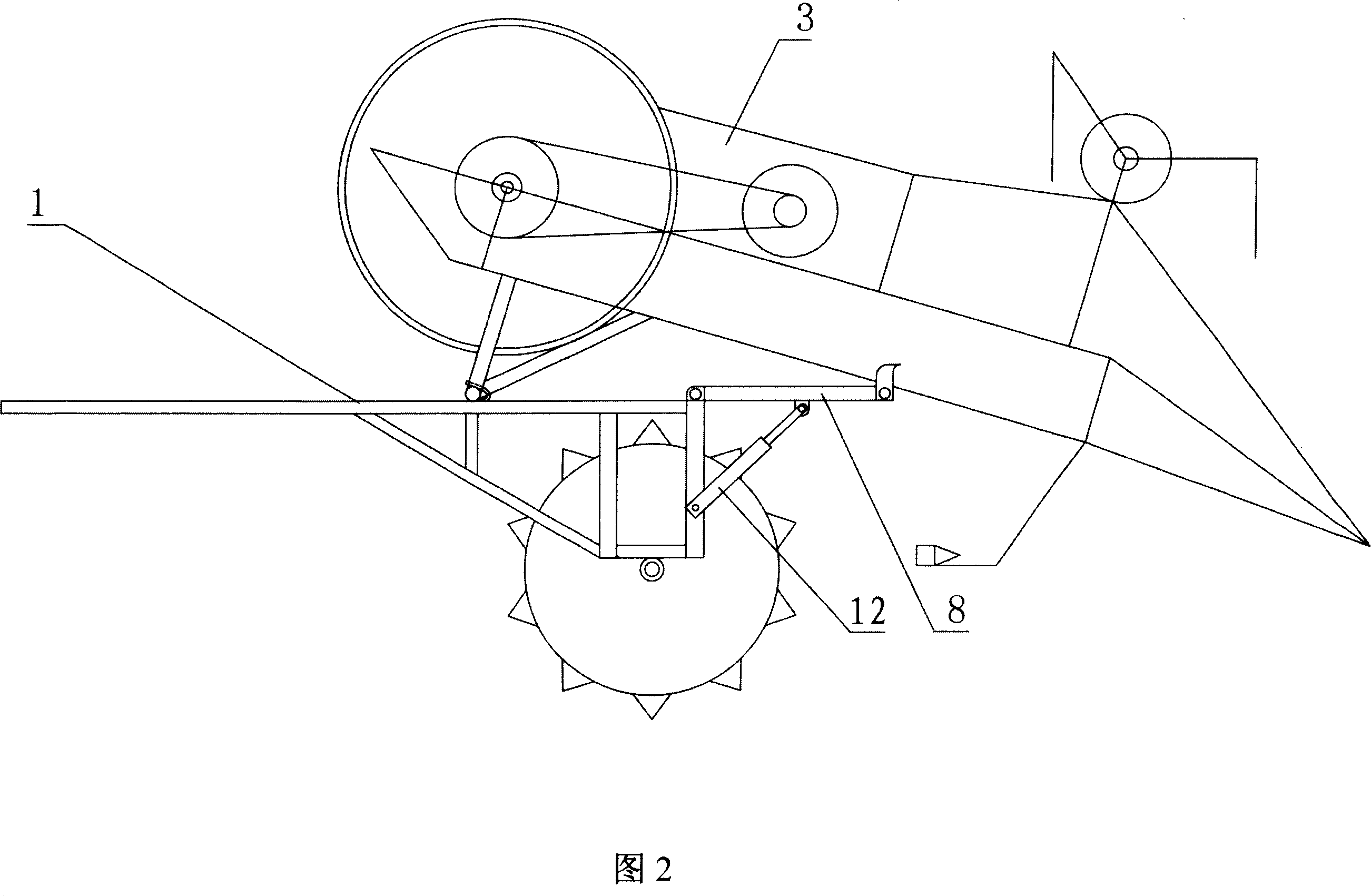

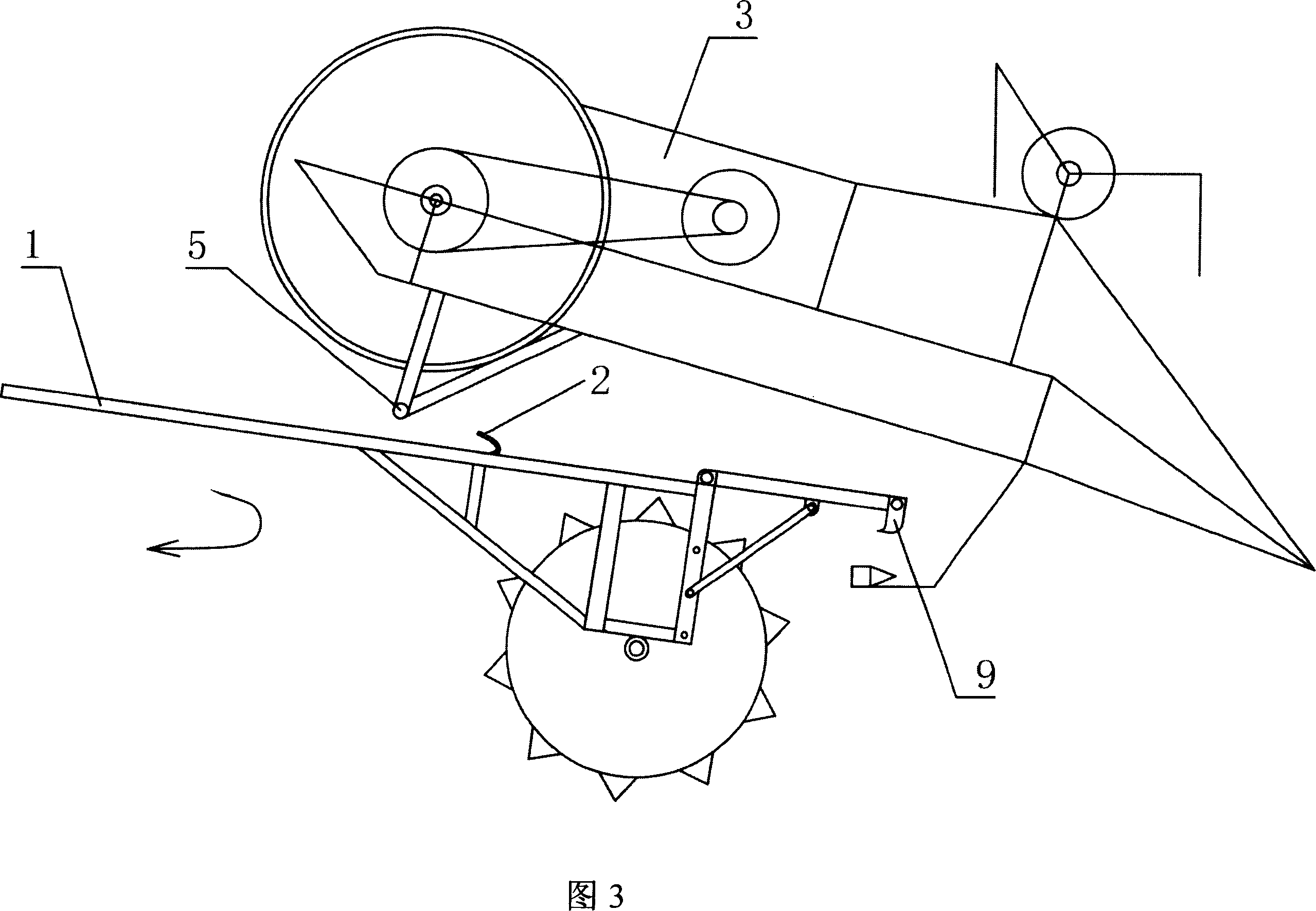

Anti-blocking subsoiler applicable to non-tillage farming

The invention relates to an anti-blocking subsoiler applicable to non-tillage farming. The subsoiler comprises a rack, a stubble cutting device, a subsoiling device and depth limiting devices. The stubble cutting device is located at the front end of the rack; the subsoiling device is arranged behind each stubble cutting device; the depth limiting devices are located at the left and right ends ofthe rack; by adopting a cambered inverted trapezoidal high-strength subsoiler, a chamfer is arranged at one end of the advancing direction, the phenomenon of grass hooking can be lowered, the subsoiler is arranged in a V-shaped, and the subsoiling range is effectively enlarged; the subsoiler is applicable to non-tillage subsoiling operation, the problems that due to residual stubble blocking, theresistance is excessively large, machines and tools are blocked, and the efficiency is low are effectively avoided, and the subsoiling efficiency is effectively improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

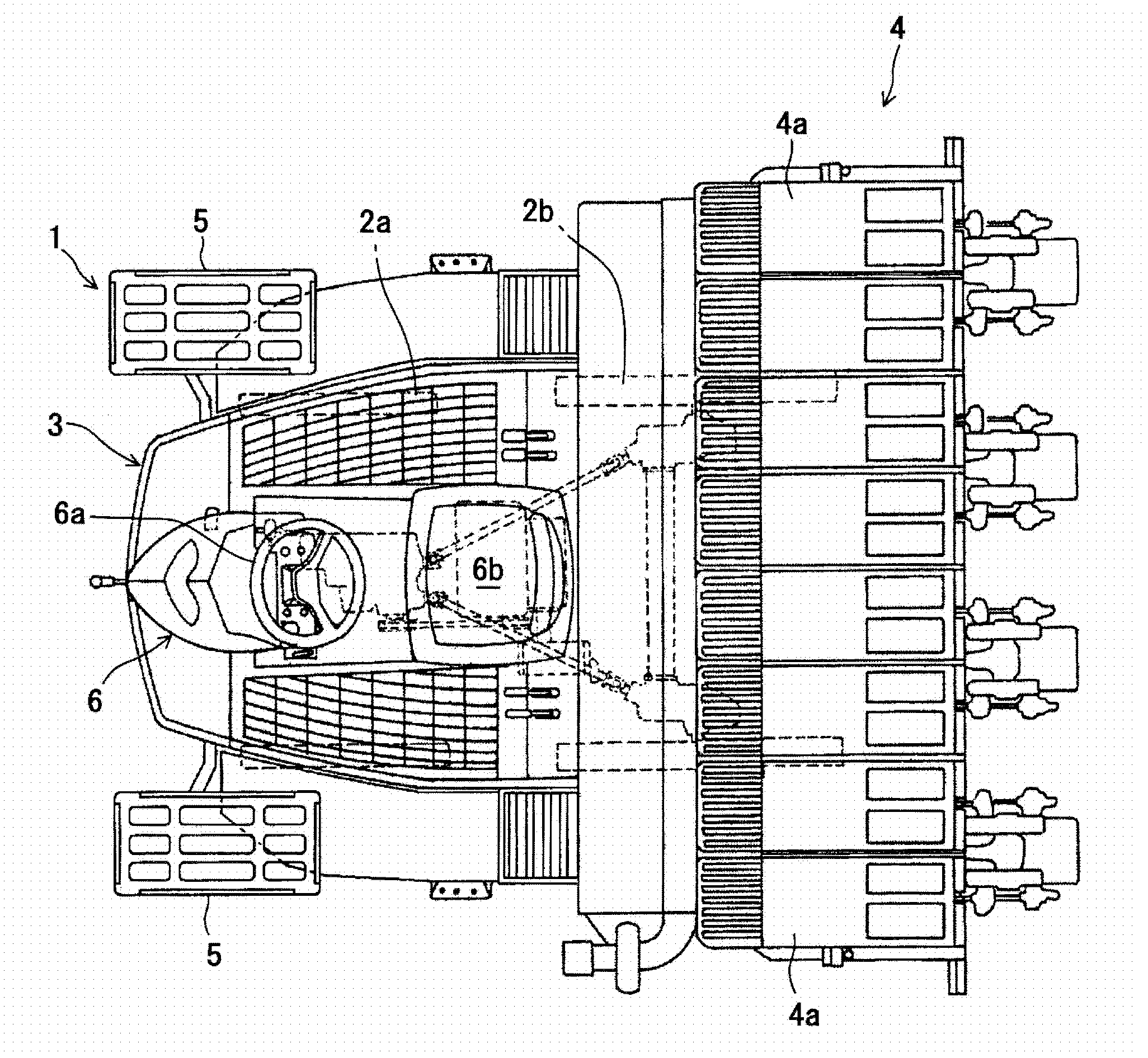

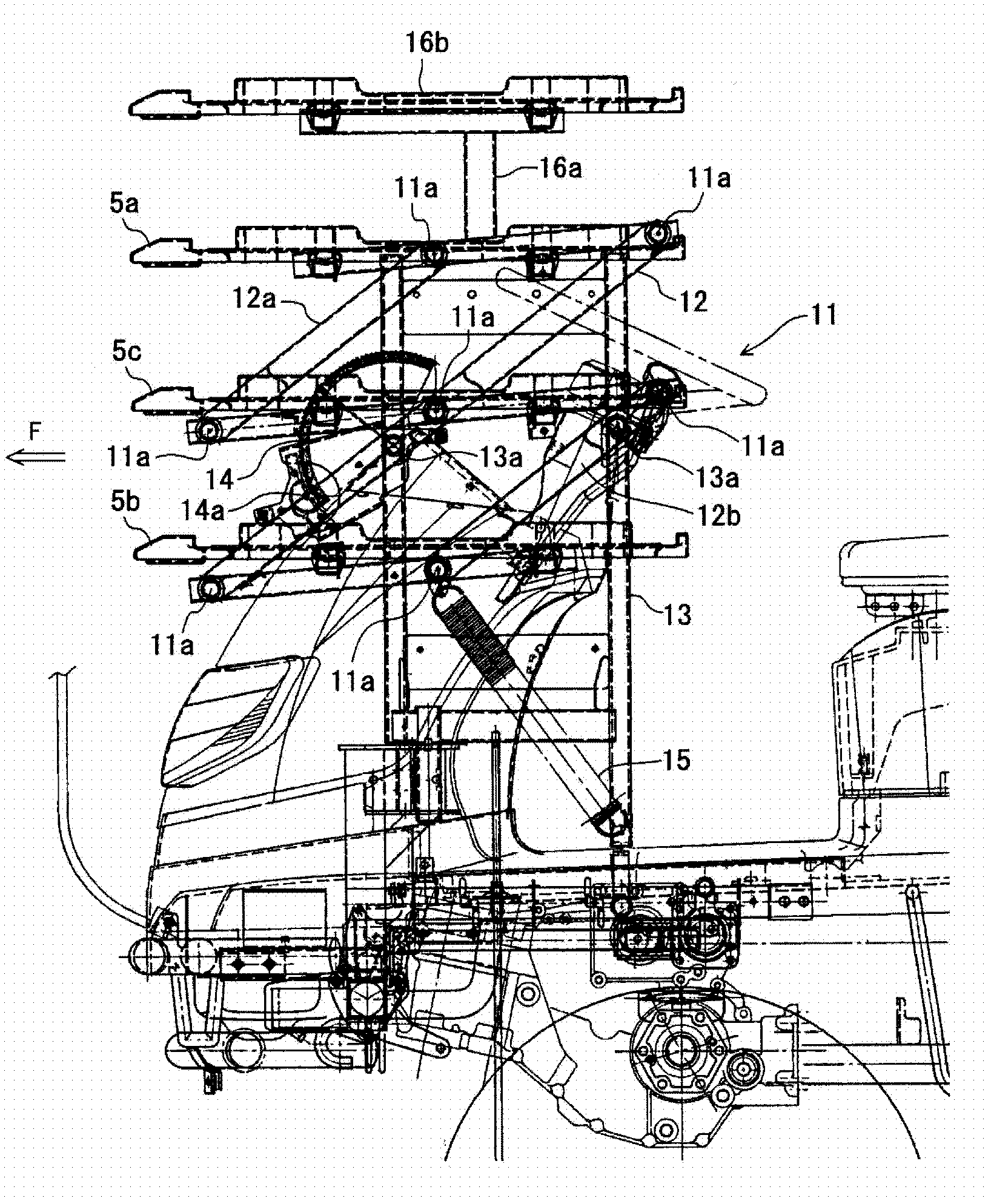

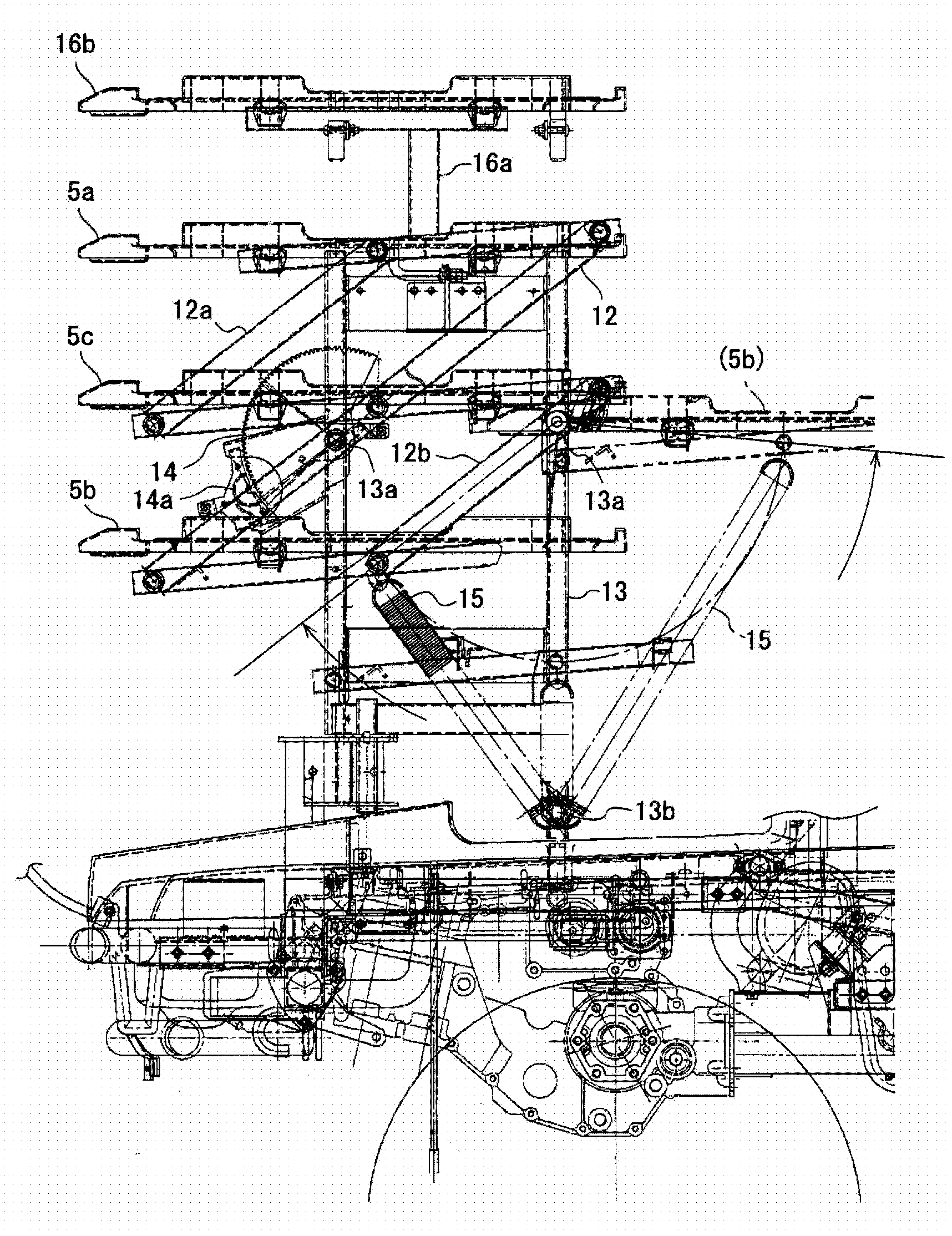

Seedling transplanting machine

InactiveCN102742407BInhibitionImprove work efficiencyAgricultural vehiclesAgriculture and animal husbandary industrySeedlingBiology

A seedling transplanting machine has a preparation seedling rack, thus even if a machine body shakes due to unevenness of a field, rotation of an expansion support mechanism can be suppressed, even if the number of preparation seedling loading benches is increased, the seedling can be put in and taken out easily, and even if the seedling is loaded, motion of the expansion support mechanism can not be affected. A side part of a driving car body is provided with the preparation seedling rack, the preparation seedling rack is provided with a force application device used for supporting the plurality of preparation seedling loading benches to form the movable expansion support mechanism and applying force to the expansion support mechanism. The seedling transplanting machine is provided with a switching mechanism which enables the expansion support mechanism to act, in order to switch stack forms of the plurality of preparation seedling loading benches arranged along an upward-and-downward direction and expansion forms of the plurality of preparation seedling loading benches arranged along a forward-and-backward direction, when the preparation seedling rack is switched from the stack form to the expansion form, the force application device applies a force to the expansion support mechanism towards an expansion form side at a movement starting end side, and applies a force to the expansion support mechanism towards a stack form side at a movement terminal side.

Owner:ISEKI & CO LTD

Header of agricultural harvester

The invention discloses a header of an agricultural harvester. The header comprises a header assembly, an auger assembly and a reel assembly, wherein the length of the header assembly, the length of the auger assembly and the length of the reel assembly can be adjusted, and the header assembly comprises a header fixed frame, two header movable frames, a shielding frame arranged between the header fixed frame and the header movable frames, rotating blocks rotationally arranged on the shielding frame, rollers rotationally arranged on the rotating blocks and a first adjusting device which is connected with the header movable frames and the header fixed frame and is used for adjusting the distance between the two header movable frames. According to the header of the agricultural harvester, the length of the header can be larger, the limitation of the situation of a transportation road on the header is less ignored when the header is too long, the transportation flexibility of the harvester is improved, the storage space of the harvester is reduced, and compared with a folding header, the header can be well retracted and can be continuously used, when the area of a farm is irregular, the harvester can be flexibly shrunk for continuous harvesting, and the operation adaptability is improved.

Owner:ANHUI POLYTECHNIC UNIV

Automatic water surface flexible floating object collecting device based on jet principle

The invention discloses an automatic water surface flexible floating object collecting device based on a jet principle, and belongs to the technical field of water surface pollutant treatment. The device comprises a device platform, an energy supply unit, a suction unit and a collecting and propelling unit; the energy supply unit comprises a solar cell module and an energy storage module; the suction unit adopts a jet flow suction unit, wherein the jet flow suction unit comprises a suction pipe, a high-pressure pump and a jet flow assembly; and the collecting and propelling unit comprises a storage box, a trash rack and a water outlet. According to the automatic water surface flexible floating object collecting device based on the jet principle, floating object suction and collection and device platform propelling are integrated, a complex and huge hydraulic system and a matched mechanical device in a conventional technology are avoided, and therefore the device is concise and efficient in design. Compared with the prior art, the device has the advantages of being concise and compact in structure, high in working adaptability, high in removing efficiency, good in maneuverability and capable of stably working for a long time.

Owner:TSINGHUA UNIV

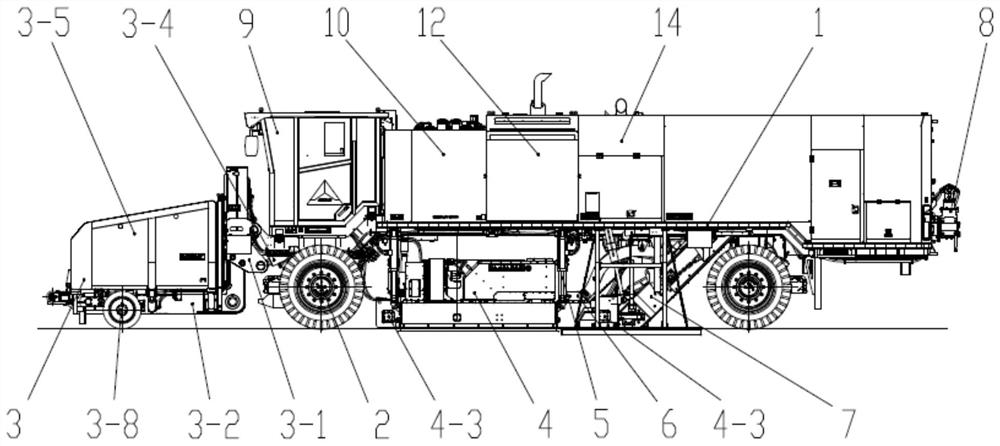

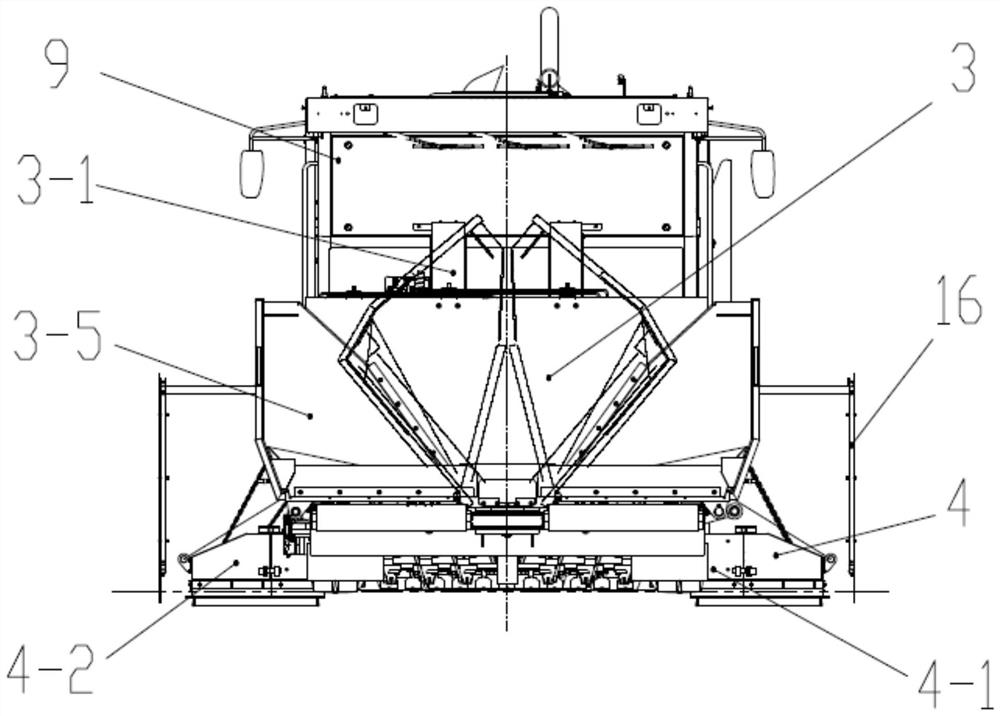

Remixer

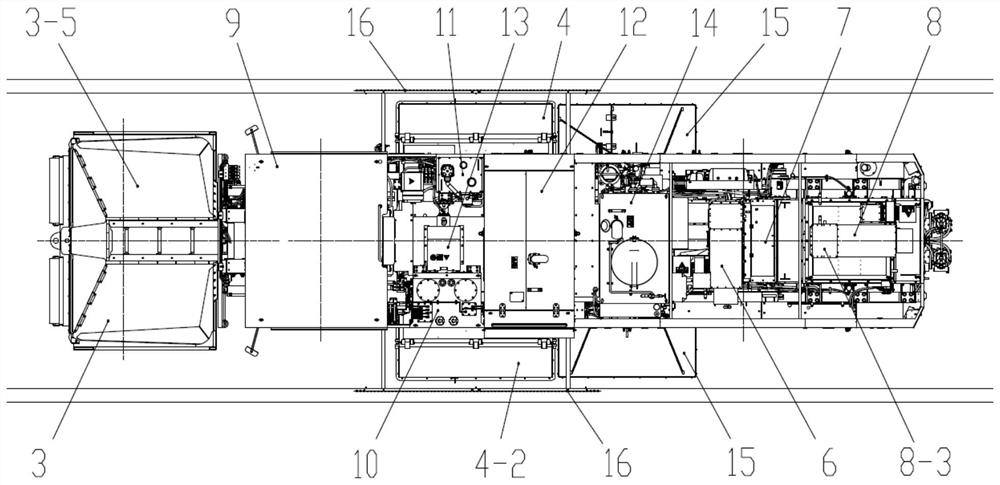

ActiveCN111676774AReduce fatigueAvoid personal injuryRoads maintainenceFlue gasStructural engineering

The invention discloses a remixer comprising a rack and a material receiving device. The material receiving device is hinged to the front portion of the rack; the material receiving device comprises afixing frame, a lifting frame, a hopper lifting oil cylinder, a hopper variable-amplitude oil cylinder, a hopper, a hopper supporting beam and a hopper steering cylinder. Hopper supporting wheels arefixedly arranged at the two ends of the hopper supporting beam correspondingly and are in transmission connection with the hopper supporting beam through the hopper steering cylinder. The lifting frame is fixedly arranged above the hopper supporting beam, two hoppers are hinged to the horizontal section of the lifting frame, the vertical section of the lifting frame is sleeved in the fixing frame, the hopper lifting oil cylinder is arranged between the vertical section of the lifting frame and the fixing frame, and the fixing frame is hinged to the rack through a hopper variable-amplitude oilcylinder. According to the remixer, pavement grading damage is effectively avoided, the posture can be adjusted in time, and good operation adaptability is achieved; the temperature inside and outside the asphalt mixture is increased simultaneously, and good reclaimed material temperature increasing and pavement thermal connection effects are achieved; centralized treatment of process flue gas isachieved, and environmental protection and high efficiency are achieved.

Owner:JIANGSU JITRI ROAD ENG TECH & EQUIP RES INST CO LTD

Harvester

The present invention reveals one kind of harvester capable of being assembled and disassembled fast for manpower transfer. The harvester includes one frame and one harvesting mechanism capable of being separated from the frame. The frame is provided with one locating hook in the middle part for connection with the harvesting mechanism, and one push rod in the head. The push rod has adjustable height for regulating the height of the harvesting mechanism to fit the height of the crop to be harvested.

Owner:胡克仁

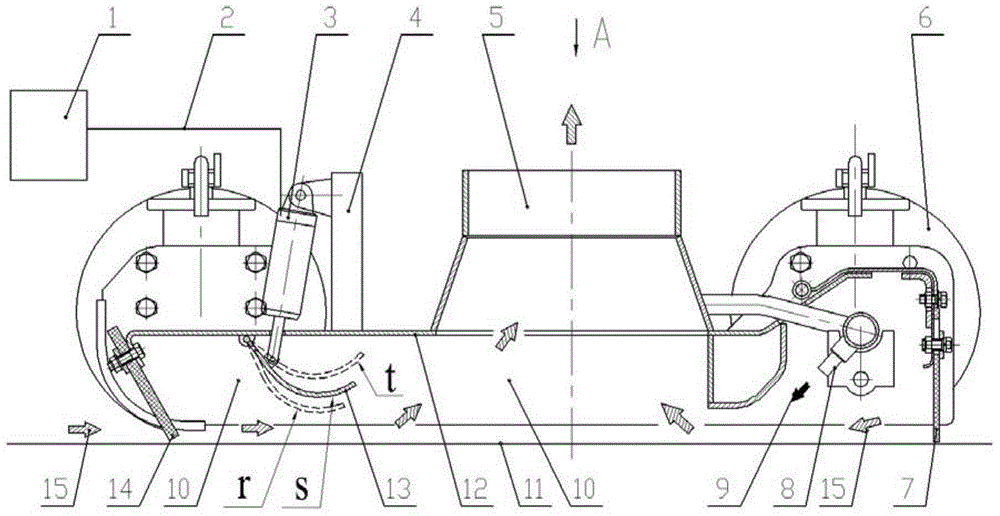

Screw hob roller and screw rolling brush combined road ice clearing machine

The invention discloses a screw hob roller and screw rolling brush combined road ice clearing machine, and belongs to the field of environmental protection machines. A rack assembly is rotatably provided with a front screw hob roller assembly, a rear screw hob roller assembly, a left screw auger shaft assembly and a right screw rolling brush assembly from front to back in sequence. The rotation direction of the right screw rolling brush assembly is opposite to the rotation direction of the front screw hob roller assembly, the rear screw hob roller assembly and the left screw auger shaft assembly, and the right screw rolling brush assembly is composed of a brush shaft, a right screw seat board, a right screw rolling brush piece, a fixing assembly, a solid brush plastomer, a plastic wire andsteel wire combination and a hydraulic motor A. The screw hob roller and screw rolling brush combined road ice clearing machine is novel and reasonable in structure, good in operation quality, high in efficiency, harmless to a road, reliable to use and especially capable of being suitable for and meeting operation of clearing thin ice and stubborn ice on the road.

Owner:HARBIN QINGYANG ELECTRIC VEHICLE TECH DEV CO LTD

Saw blade type hob and gear type hob combination road ice crushing roller

The invention relates to a saw blade type hob and gear type hob combination road ice crushing roller, and belongs to environmental protection machinery. Gear type hob assemblies and saw blade type hobassemblies are arranged at intervals between two supports seats on a roller shaft, and the saw blade type hob assembly is axially and radially positioned and circumferentially and rotatably sleeved on the roller shaft; the gear type hob assembly is fixedly arranged on the roller shaft, and all the gear type hob assemblies fixedly arranged on the roller shaft are spirally arranged along the axis as a whole; the saw blade type hob assembly comprises a semicircular saw blade, a support plate, a bearing, a fastener group and a reinforcing plate, and the gear type hob assembly comprises a pin, a star-shaped bracket, a sleeve rack, a gear hob and a compression spring. The roller has the advantages of novel and reasonable structure, strong operation adaptability, good operation quality, high removal efficiency, low damage to road, reliable use, and few failures.

Owner:HARBIN QINGYANG ELECTRIC VEHICLE TECH DEV CO LTD

Wind direction adjustable industrial refrigeration fan

InactiveCN109974173AImprove job adaptabilityHigh utility valueLighting and heating apparatusAir conditioning systemsEngineeringRefrigeration

The invention relates to the technical field of fan design, and discloses a wind direction adjustable industrial refrigeration fan. The wind direction adjustable industrial refrigeration fan comprisesa base; a supporting frame is fixedly arranged on the base; a rotating seat is hinged with the supporting frame; a rotation adjusting motor for driving the rotating seat is fixedly arranged at the lower end of the supporting frame; an outer sleeve is integrally formed on the rotating seat; a positioning column is inserted into the outer sleeve; a connecting seat is fixedly mounted on the positioning column; at least three positioning holes are formed in the positioning column in an equidistant array manner; and height adjustment screw buttons matched with and fixed to the positioning holes inthe positioning column are mounted on the outer sleeve in a screwed connection manner. The wind direction adjustable industrial refrigeration fan can quickly adjust the height, horizontal rotation direction and vertical rotation direction of air supply, and can thus meet the use requirements of various sites in the factory. Compared with a traditional refrigeration fan which is fixed to the ground and can only supply air in a single direction, the wind direction adjustable industrial refrigeration fan has better working adaptability, is simple to operate and easy to use and has very high practical value.

Owner:南昌汇达知识产权有限公司

Surface soil processing component

InactiveCN103891437AImprove job adaptabilityGuarantee and improve job qualitySpadesPloughsSoil scienceEngineering

The invention discloses a surface soil processing component, and belongs to the technical field of agricultural machines. The surface soil processing component comprises a machine frame, a clod crushing device and a rolling device. The surface soil processing component is a part of a land preparation machine, is installed at the backmost position of the land preparation machine, can achieve the functions of crushing clods and rolling surface soil, enables surface soil to be finely crushed and flattened after operation, and provides a good seedbed with the loose upper portion and the solid lower portion for growth of crop seeds. The surface soil processing component is reasonable in structural design, is convenient to use and has good effects of clod crushing and land flattening.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

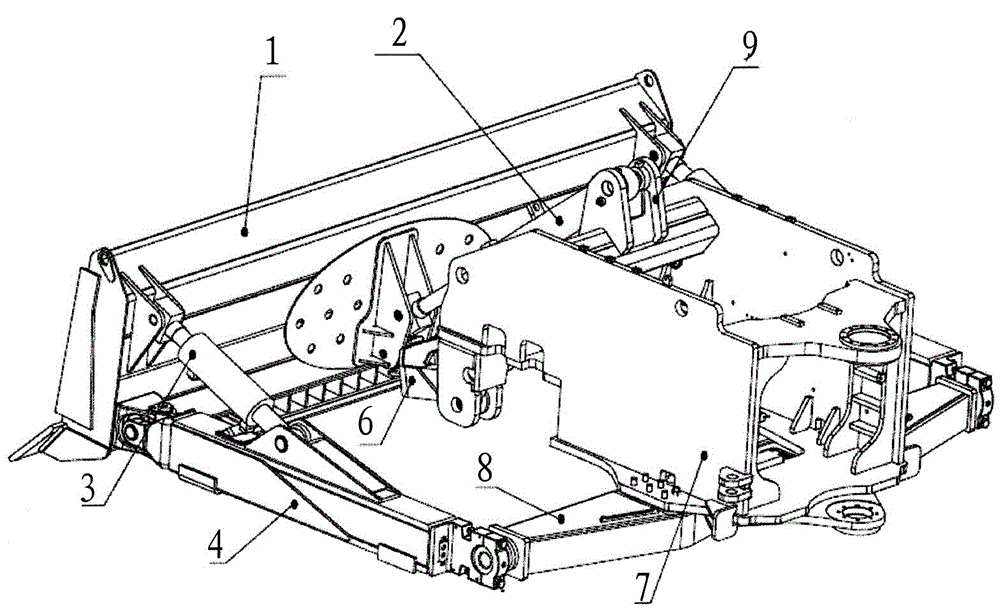

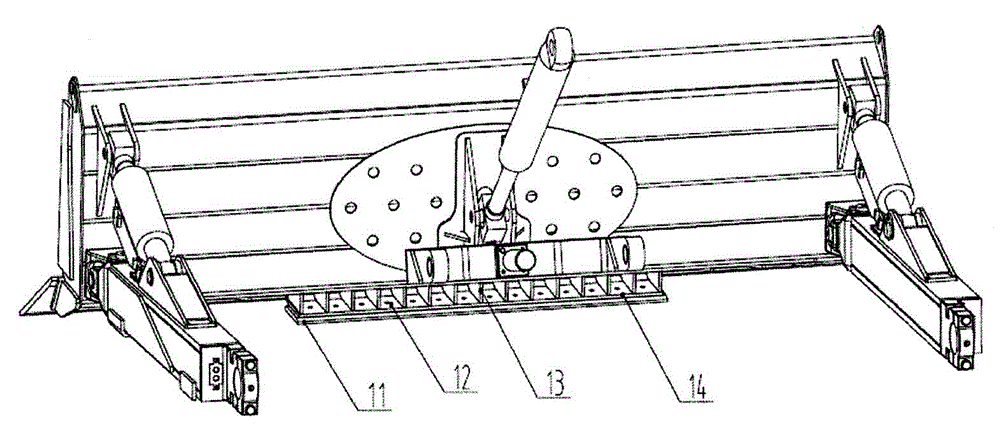

Working device of wheeled dozer

InactiveCN104612196AIncrease productivityRealize lifting actionSoil-shifting machines/dredgersVehicle frameEngineering

The invention discloses a working device of a wheeled dozer. The working device of the wheeled dozer comprises a scraper knife, big arms, sideward and forward inclined oil cylinders, a triangular support and a lift cylinder, wherein the big arms are combined with the two sides of the scraper knife respectively in a hinged mode, the sideward and forward inclined oil cylinders are connected between the scraper knife and the big arms in a hinged mode, and the triangular support and the lift cylinder are combined with the middle of the scraper knife in a hinged mode. The front end of each big arm is hinged to the scraper knife through a spherical hinge, and the rear end of each big arm is hinged to a thrust beam of a front vehicle frame through a spherical hinge; a ground flattening device is arranged below the scraper knife and at the rear of a knife edge of the scraper knife; the combined ends of each sideward and forward inclined oil cylinder and the scraper knife are hinged through a spherical hinge, and the combined ends of each sideward and forward inclined oil cylinder and the corresponding big arm are hinged through a spherical hinge; the triangular support and the lift cylinder are hinged to the middle of the scraper knife in spherical hinges, and the triangular support is hinged to the front vehicle frame through a pin shaft; the lift cylinder is hinged to a supporting cross beam of the front vehicle frame through a spherical hinge. The working device of the wheeled dozer enables a soil cutting angle of the scraper angle to be adjusted, can flatten a working face, and greatly improves production efficiency.

Owner:ZHENGZHOU YUTONG HEAVY IND

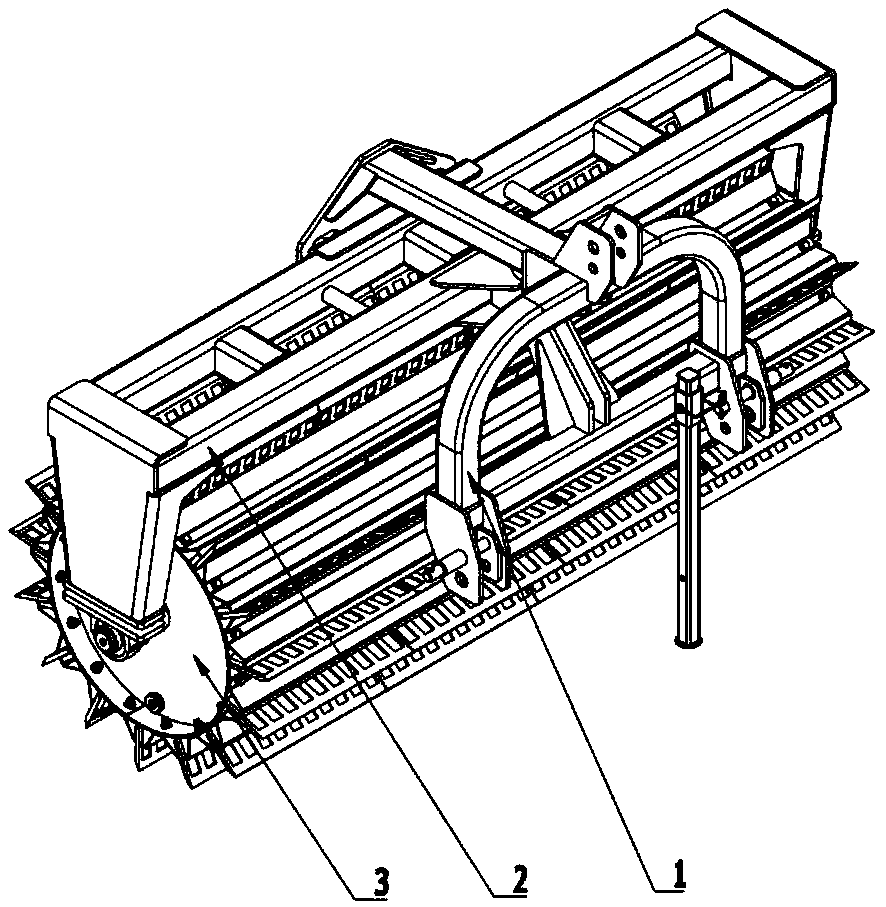

Roller type press cutting machine

PendingCN108834454AIdeal overturning effectWon't stickSpadesPloughsEngineeringMechanical engineering

The invention relates to a roller type press cutting machine, and belongs to the technical field of agricultural machines. The roller type press cutting machine comprises a hanging assembly connectedwith a traction device, a supporting assembly connected with the hanging assembly, and a roller assembly which is supported below the supporting assembly. Press cutters which axially extend are uniformly distributed on the outer circumference of a roller body of the roller assembly at intervals, elastic dumping plates with V-shaped sections are installed between adjacent press cutters, and the twosides of each elastic dumping plate are close to the opposite surfaces of the corresponding adjacent press cutters respectively. During work, only traction force generated when the roller body movesprovides the power consumed by all work, compared with an existing plough-back device, power consumption is greatly reduced, it can be ensured that during press cutting work, the roller body cannot adhere to a furrow, and a desired green manure plough-back operation effect can be kept all the time; the structure of the roller type press cutting machine is simplified, and plough-back operation of various kinds of green manures in farmland, orchards, forest land and the like can be considered.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

A variable flow area suction nozzle for road sweeping vehicles

The invention discloses a variable flow area suction nozzle applied to a road sweeper. The variable flow area suction nozzle comprises a suction nozzle body and a conveying pipe arranged on the suction nozzle body, as well as a front air baffle plate arranged at the front end of the suction nozzle body and a rear air baffle plate at the back end of the suction nozzle body, wherein air inlet passages are formed between the bottom ends of the front air baffle plate and the rear air baffle plate and road surface when the sweeper works; a suction inner cavity communicated with the conveying pipe is formed among the suction body, the front air baffle plate and the rear air baffle plate; a tongue plate arranged on the suction nozzle body is arranged in the suction nozzle inner cavity; and the tongue plate can swing when the sweeper works so that the cross-sectional flow area of the suction inner cavity is increased or reduced. By optimizing the flow field, the suction nozzle disclosed by the invention can guarantee relatively good adaptability of the road sweeper to dense garbage and light garbage on the ground, so that the adaptability of the road sweeper to the road garbage is enhanced, and the sweeping quality and working efficiency of the road sweeper are improved.

Owner:HUNAN UNIV

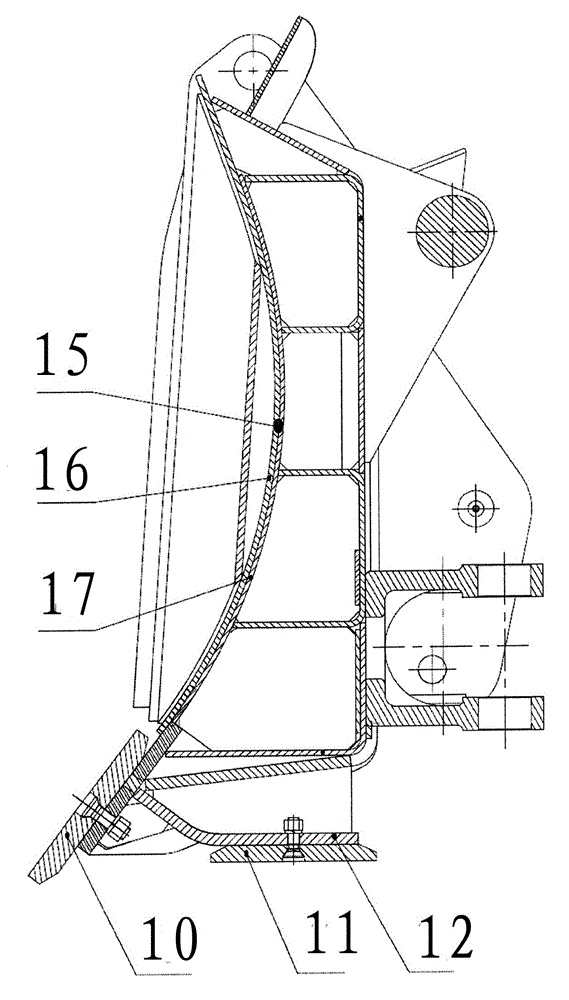

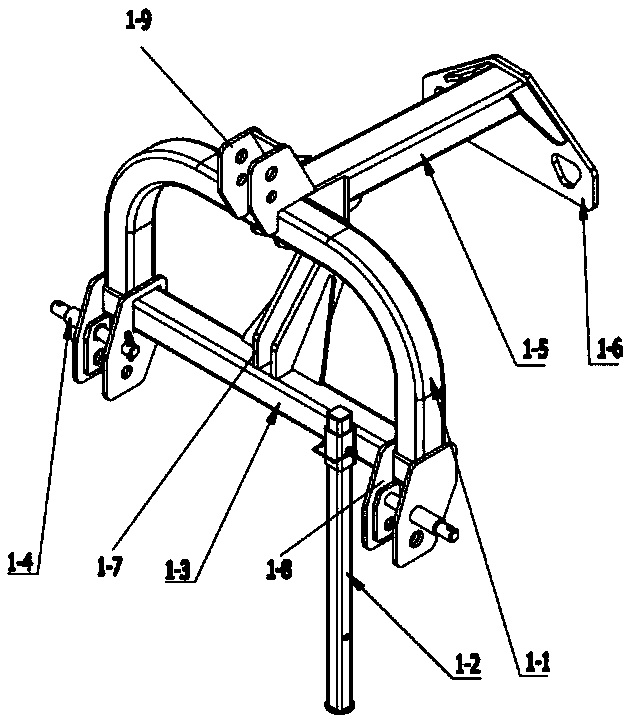

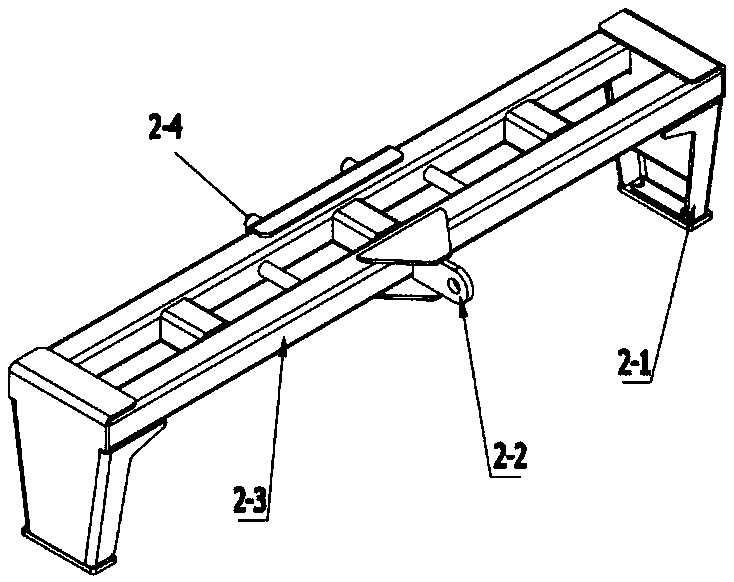

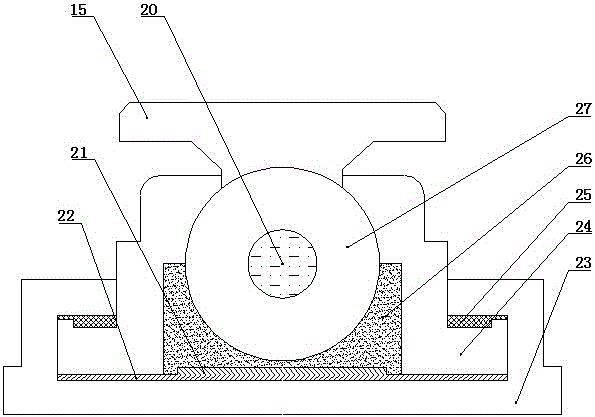

A front outrigger structure of a highway bridge erection lifting device

ActiveCN105421243BImprove job adaptabilityReduce vibrationBridge erection/assemblyDrive wheelSlide plate

The invention relates to a front supporting leg structure of novel highway bridging hoisting equipment. The front supporting leg structure of the novel highway bridging hoisting equipment comprises a transverse moving rail. The left and right portions of the upper surface of the transverse moving rail are sequentially connected with a driven wheel box and a driving wheel box. The upper ends of the driving wheel box and the driven wheel box are both connected with saddle structures. The upper ends of the saddle structures are connected with a cross beam, and the left and right sides of the upper end of the cross beam are both connected with rotary supports. A pull rod A and a pull rod B are connected between lug plates, and a buffering mechanism is arranged in the connecting position of the pull rod A and the pull rod B. A sphere body is arranged in the middle of each rotary support, an oil storage chamber is arranged inside each sphere body, an upper semi-spherical shell is arranged on the upper side of each sphere body, and a lower semi-spherical shell is arranged on the lower side of the sphere body. A pressed Teflon sliding plate is arranged on the lower side of each lower semi-spherical shell, a stainless steel plate is arranged on the lower side of each pressed Teflon sliding plate, and an anti-drawing Teflon sliding plate is arranged in the middle of the connecting position of a sliding box and each upper semi-spherical shell. The front supporting leg structure of the novel highway bridging hoisting equipment has the advantages of being simple in structure, stable in operation, high in construction efficiency and convenient and rapid to operate.

Owner:HENAN SINOKO CRANES

Leaf pickup and compression device for lawns

The invention relates to a leaf pickup and compression device for lawns. The leaf pickup and compression device comprises carriers, wheels, a guard plate and a pickup device. The wheels are fixed at front ends of the carriers, the pickup device is arranged on the rear between the carriers, and the guard plate is mounted above the pickup device. The leaf pickup and compression device travels on a lawn, needle teeth on the pickup device contacts with the ground to directly pick leaves up. When the needle teeth with leaves move into corresponding grooves of a scraping plate, leaves can be taken off into a propelling barrel, a propelling helical blade rotates to extrude leaves to one end, and the leaves can fall into a main compression barrel through a square connecting barrel. A main compression helical blade in the main compression barrel rotates to press the leaves into a replaceable barrel. When extrusion is at certain density, an adjusting rod is rotated to take off the replaceable barrel, and another replaceable barrel is replaced to operate continuously. During operating of the compression device, the leaves and other biomasses can be directly picked up and extruded. The leaf pickup and compression device is low in cost, high in production efficiency and operating adaptability, and widely applicable to popularization and application.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

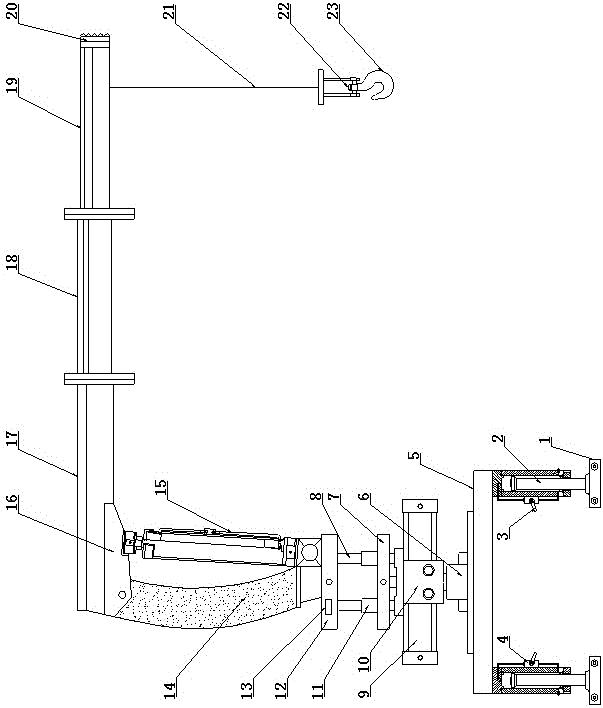

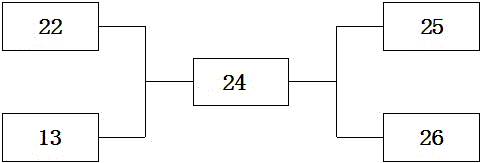

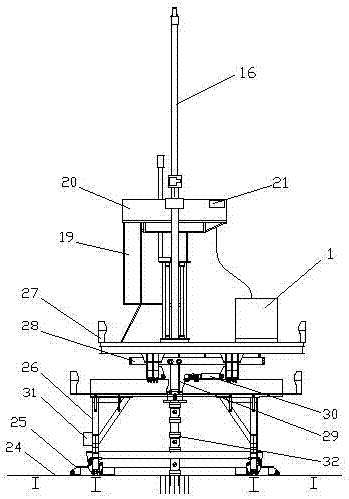

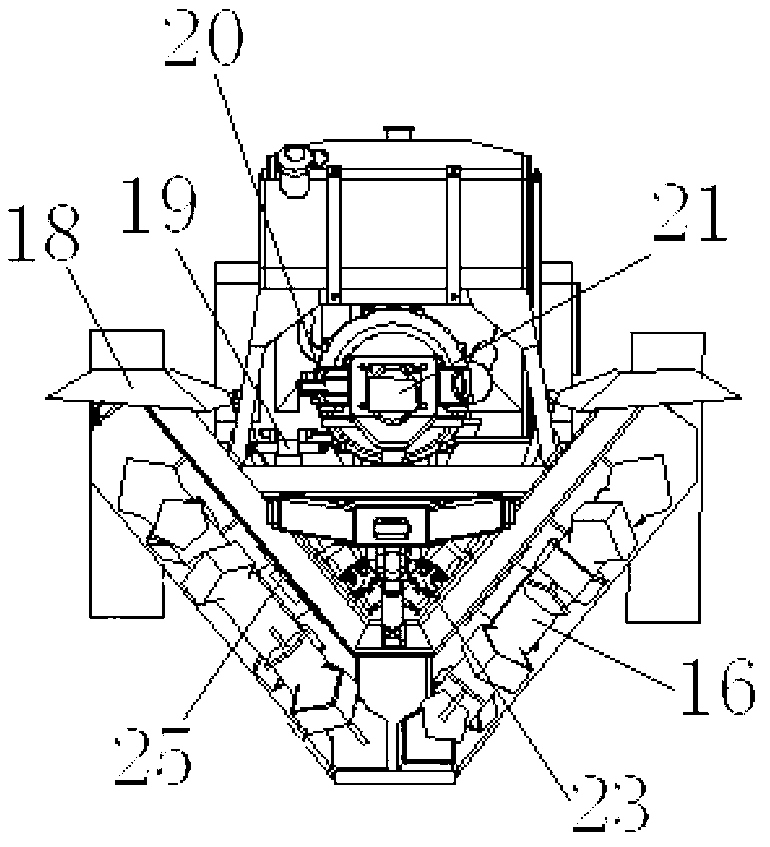

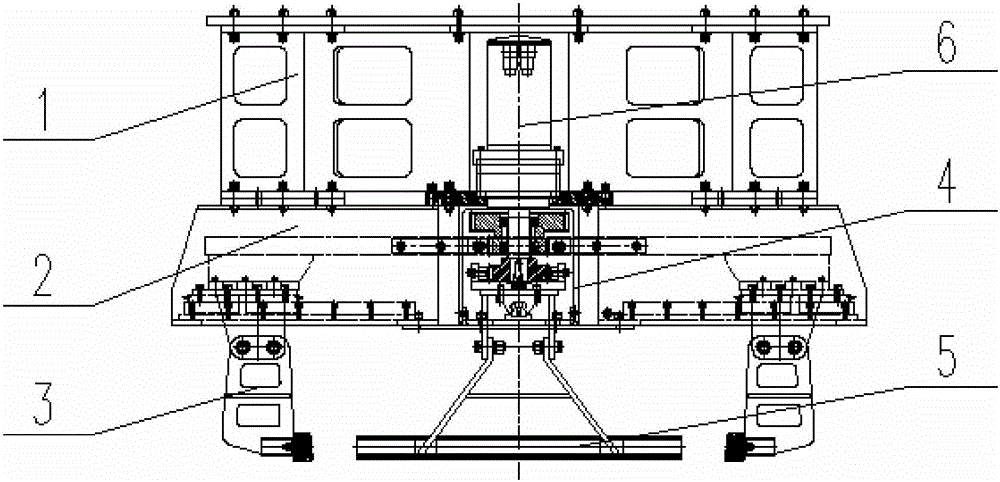

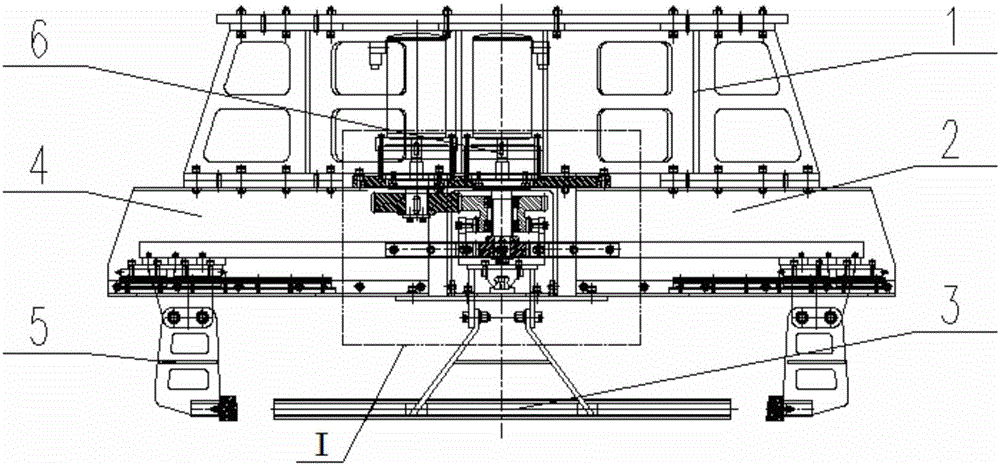

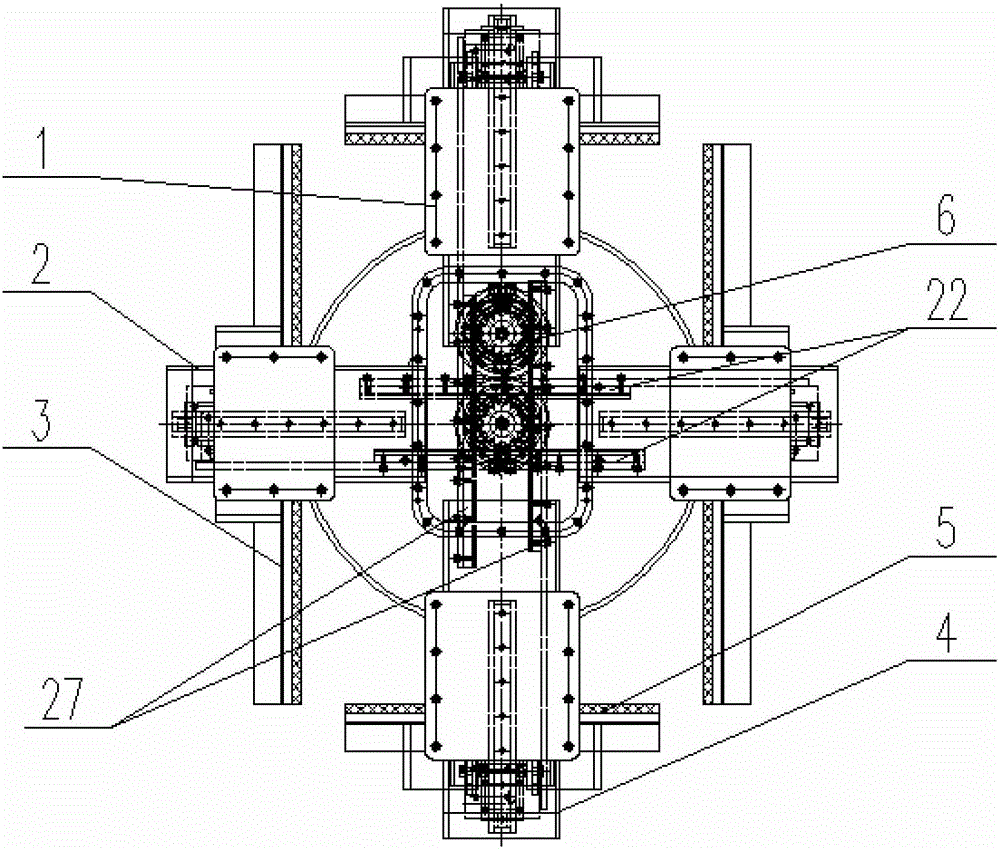

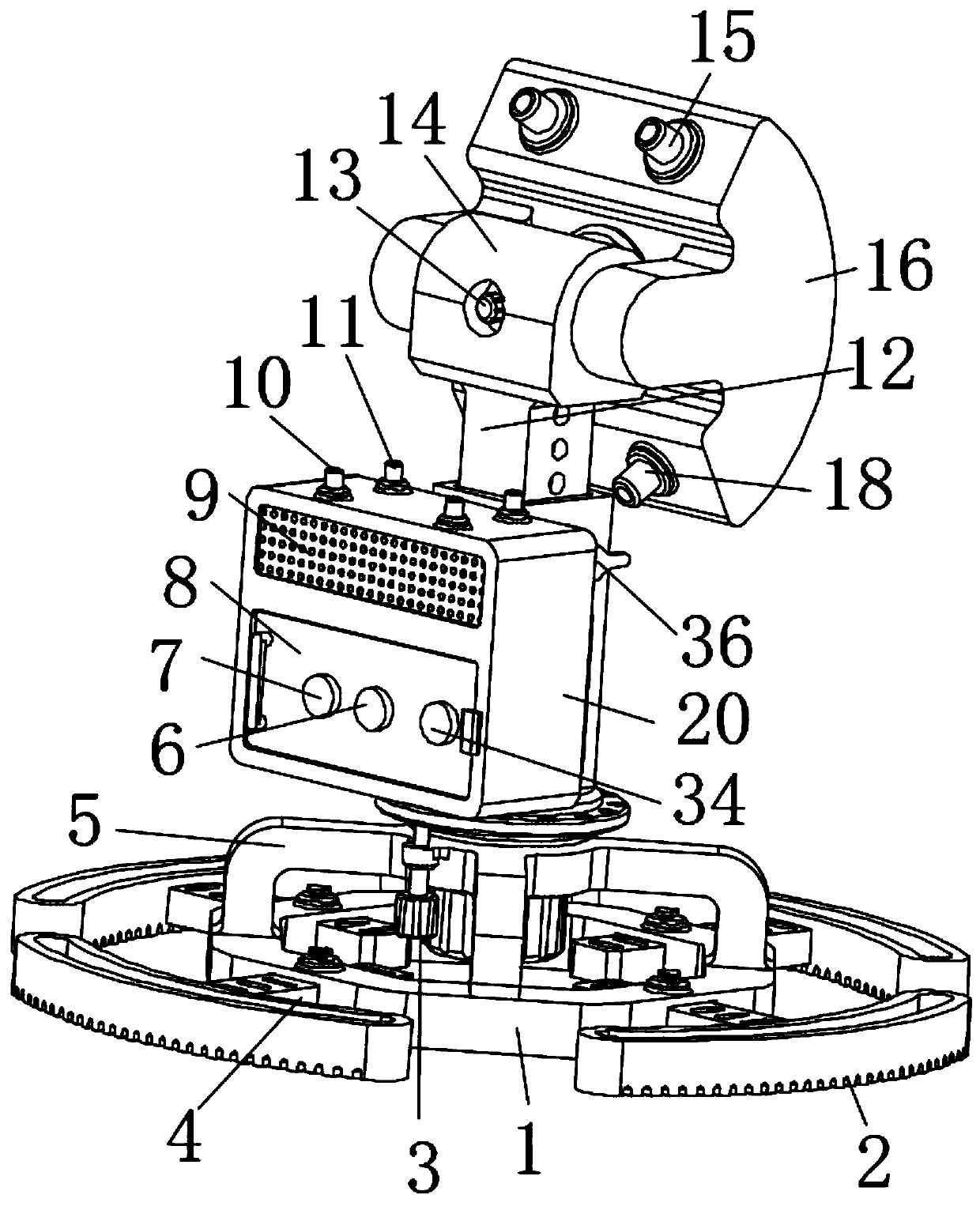

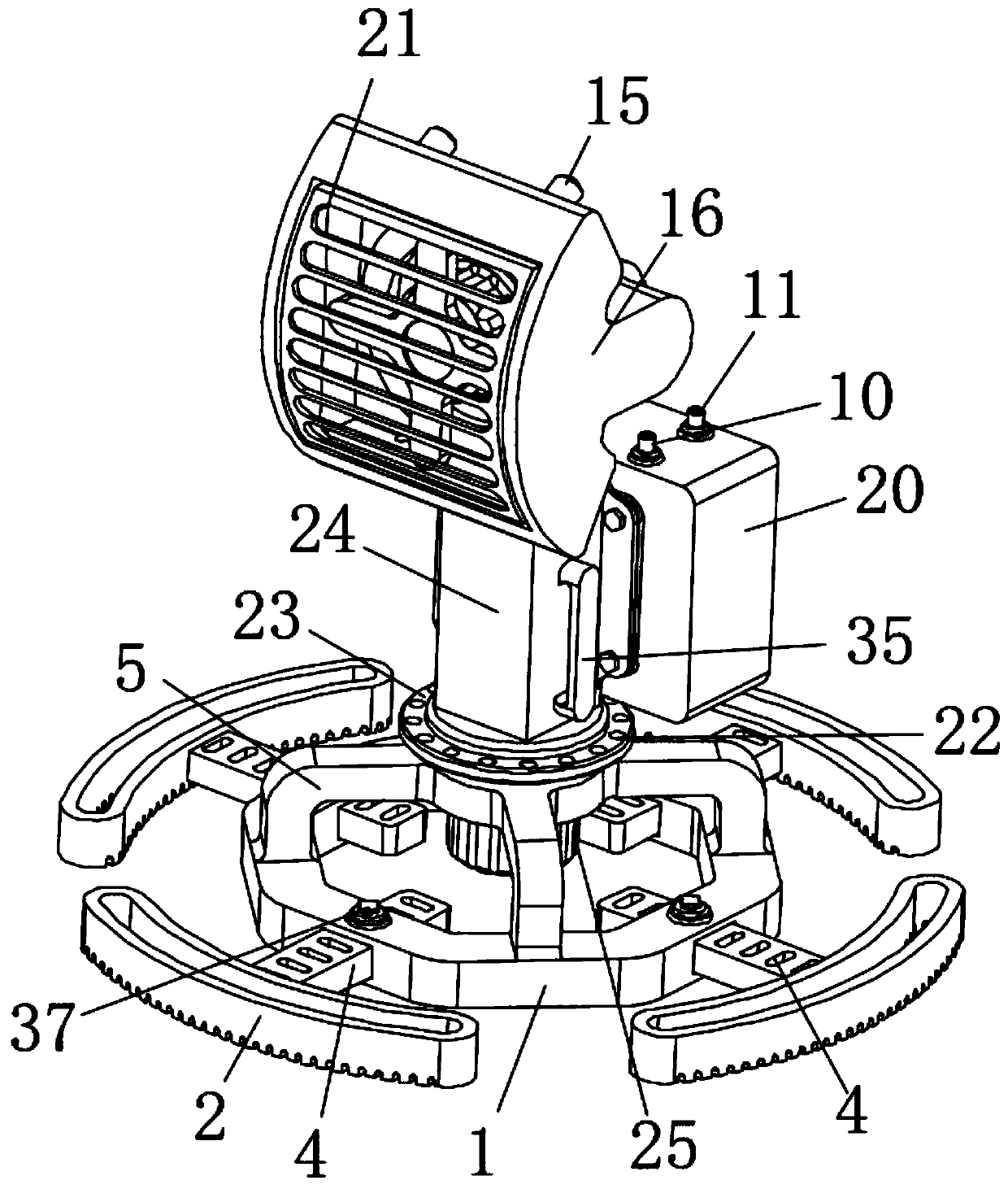

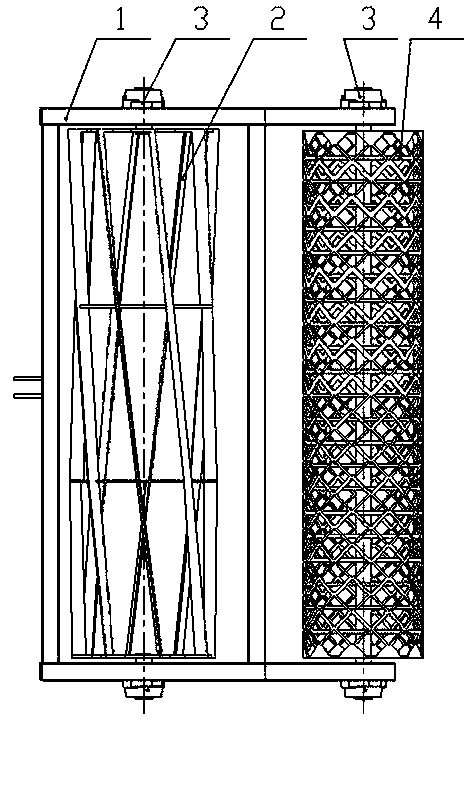

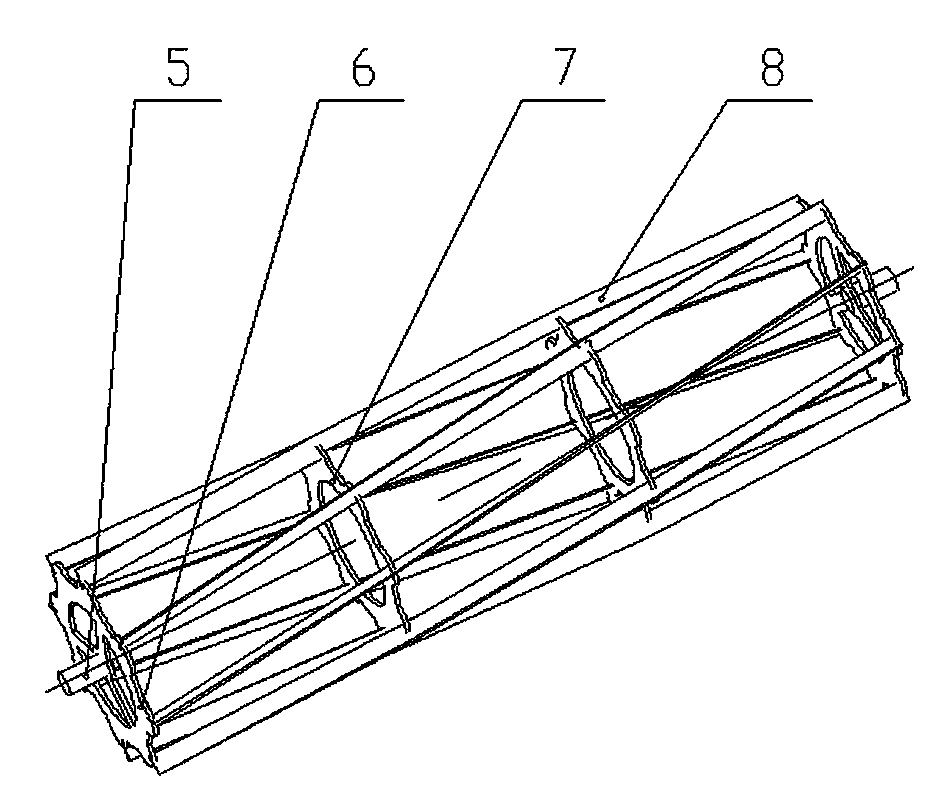

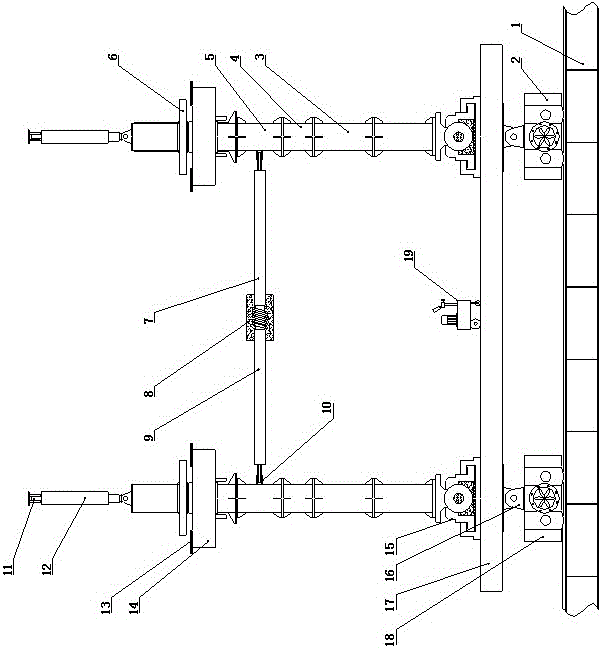

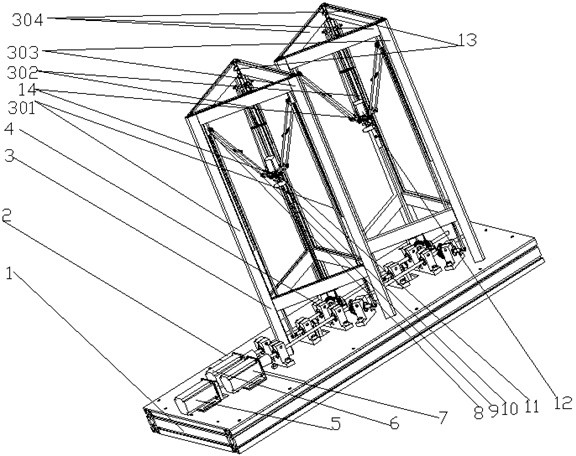

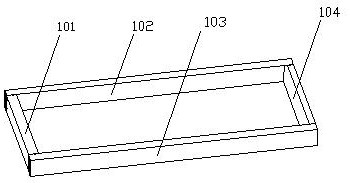

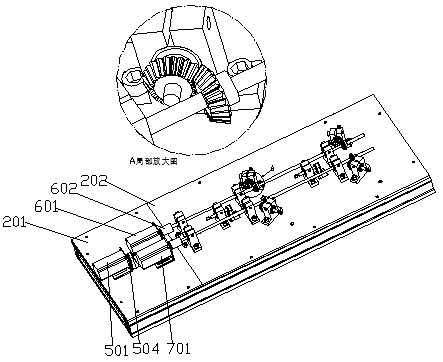

An industrial double delta parallel robot structure and control system

ActiveCN107486843BRealize swing controlImprove job adaptabilityProgramme-controlled manipulatorControl systemControl engineering

An industrial double Delta parallel robot structure and control system includes an aluminum profile base 1 and a support base plate 2, an aluminum profile frame 3, bearings and bearing housings 4, a first kinematic chain 5, a second kinematic chain 6, and a third kinematic chain 7. Guide rail slider assembly 8, fisheye ball bearing assembly 9, parallel arm 10, actuator fixture 11, actuator 12, limit switch 13, photoelectric switch 14, control system 15, first kinematic chain 5, second The second kinematic chain 6 and the third kinematic chain 7 connect the double delta parallel robots to work in series, and complete the same work under the action of the STC single-chip microcomputer controller, changing the single operation of the existing delta parallel robot or the low efficiency of the independent operation of two single delta parallel robots. Disadvantages such as high cost and small working space, the actuator drives the pneumatic suction cup to rotate through the installation of a motor and a coupling to realize the control of the rotation and alignment of the operating object, and has strong operational adaptability and wide adaptability.

Owner:CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com