Preparation method and application of high-performance high-solid-content low-viscosity acrylic resin

An acrylic resin, high solid content technology, applied in the direction of coating, can solve the problems of unsatisfactory appearance decoration, poor paint film fullness, unfavorable environmental protection and other problems, achieve excellent color retention, low viscosity, less solvent usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: The preparation method of the high-performance, high-solid content and low-viscosity acrylic resin provided by this embodiment, in parts by weight, comprises the following steps:

[0036] (1) Preparation of drip feed: add 10-20 parts of cycloalkyl methacrylate monomer, 15-30 parts of non-functional acrylate, hydroxyl-containing (meth)acrylate or its derivatives to the high slot 8-10 parts, 0.5-2 parts of methacrylic acid, 8-15 parts of vinyl monomer, 0.3-0.6 parts of initiator, stir and mix well;

[0037] Among them, the cycloalkyl methacrylate monomer is one of cyclohexyl methacrylate, tert-butylcyclohexyl methacrylate, trimethylcyclohexyl methacrylate, isobornyl methacrylate or a mixture thereof ;

[0038] The non-functional (meth)acrylate is one of methyl methacrylate, ethyl methacrylate, butyl acrylate or a mixture thereof; the vinyl monomer is styrene or acrylonitrile; the initiator is Azobisisobutyronitrile or dibenzoyl peroxide; hydroxyl-containin...

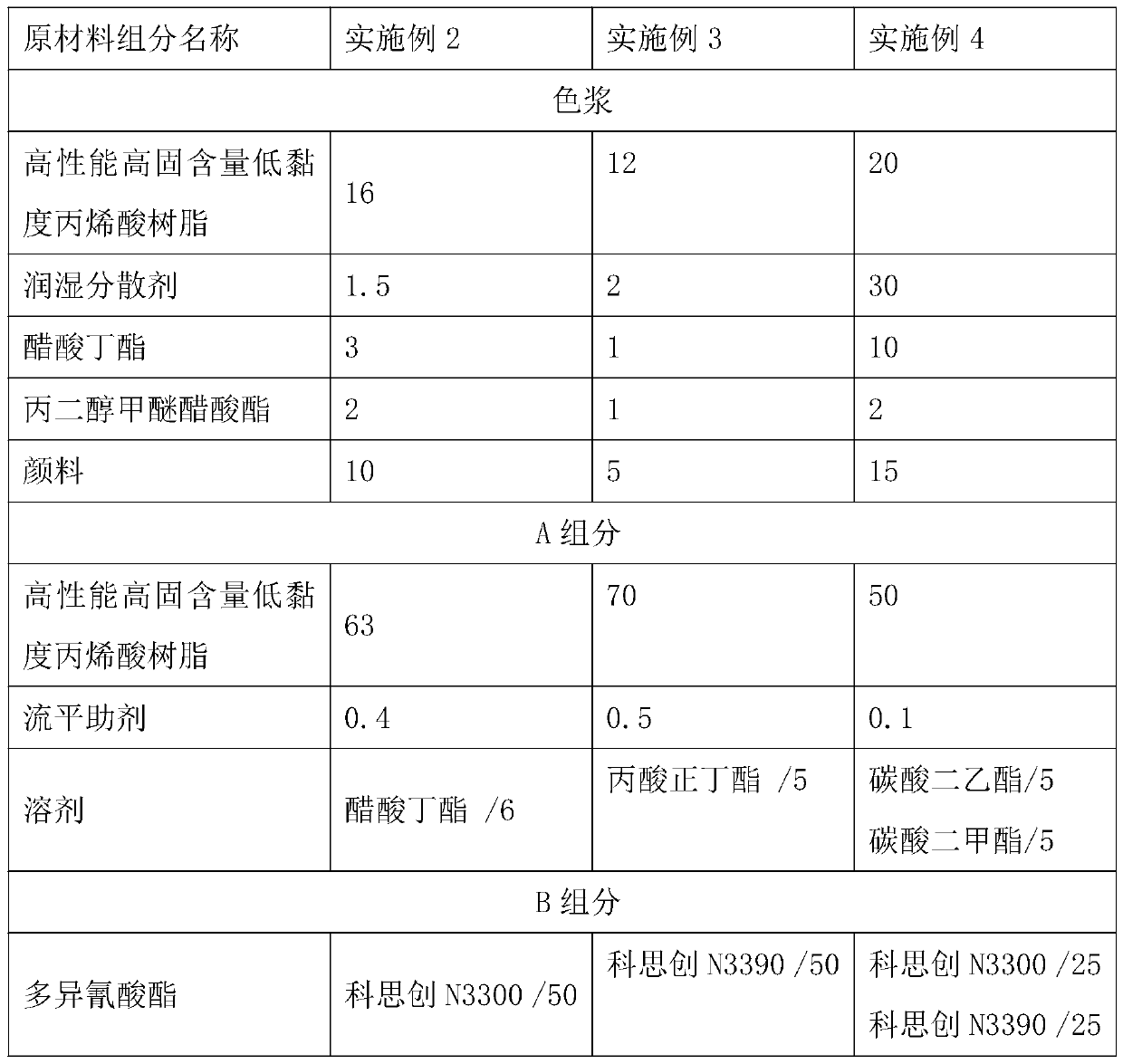

Embodiment 2

[0050] The preparation method of the high-performance, high-solid content and low-viscosity acrylic resin provided in the examples, and the environment-friendly automotive coating prepared by using the high-performance, high-solid content and low-viscosity acrylic resin, are basically the same as in Example 1, except that :

[0051] Add 15 parts by weight of cyclohexyl methacrylate or tert-butylcyclohexyl methacrylate, trimethylcyclohexyl methacrylate, one of isobornyl methacrylate, 20 parts by weight of methyl methacrylate , ethyl methacrylate, one of butyl acrylate, 9 parts by weight of hydroxyethyl methacrylate or hydroxyethyl acrylate, 1.5 parts by weight of methacrylic acid, 10 parts by weight of styrene or acrylonitrile, 0.4 parts by weight of even Azodiisobutyronitrile, after mixing uniformly, dripping material is obtained; in the reactor that stirring paddle, thermometer, condenser are housed, add 30 parts by weight of butyl acetate, the dipropylene glycol methyl ether...

Embodiment 3

[0053] The preparation method of the high-performance high-solid-content low-viscosity acrylic resin provided by this embodiment is basically the same as that of Example 1, except that:

[0054] Add 10 parts by weight of tert-butylcyclohexyl methacrylate, 5 parts by weight of methyl methacrylate, 10 parts by weight of butyl acrylate, 8 parts by weight of hydroxyethyl acrylate, 0.3 parts by weight of methacrylic acid, 12 The acrylonitrile of parts by weight, the dibenzoyl peroxide of 0.3 parts by weight, after mixing homogeneously, drip feed is made; In stirring paddle, thermometer, condenser reactor, add 5 parts by weight of n-butyl propionate, 10 parts by weight Propylene glycol methyl ether acetate in parts by weight is heated to 90°C to prepare a stirring material; the dripping material is added dropwise to the reaction kettle at a uniform speed within 1.5 hours, and after the heat preservation is continued for 3 hours, the temperature is lowered and the material is filtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com