Remixer

A remixing machine and frame technology, applied in the field of road maintenance equipment, can solve problems such as poor adaptability to operations and inability to adjust posture in a timely manner, and achieve good effects of raising temperature, reducing direct sunlight, and reducing fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

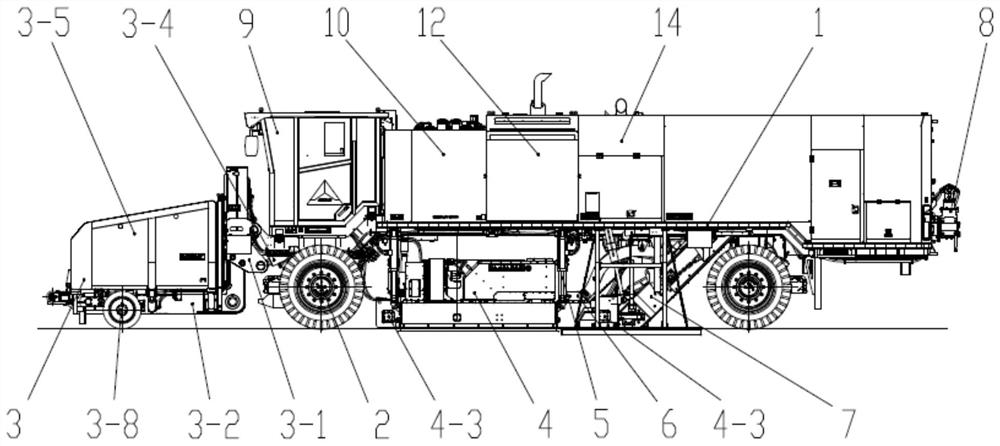

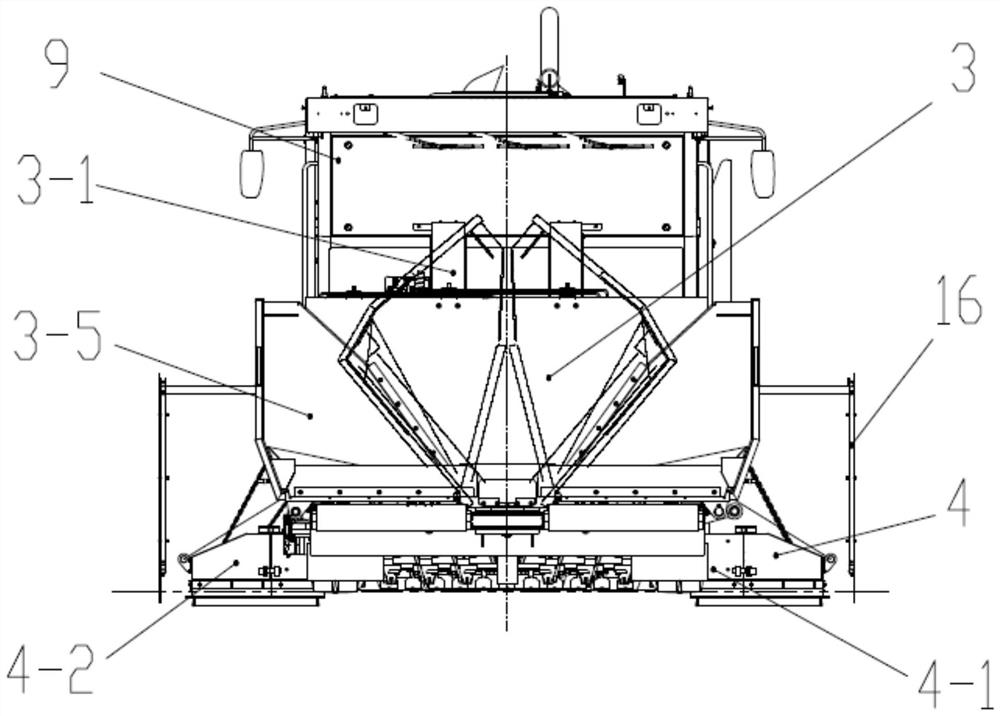

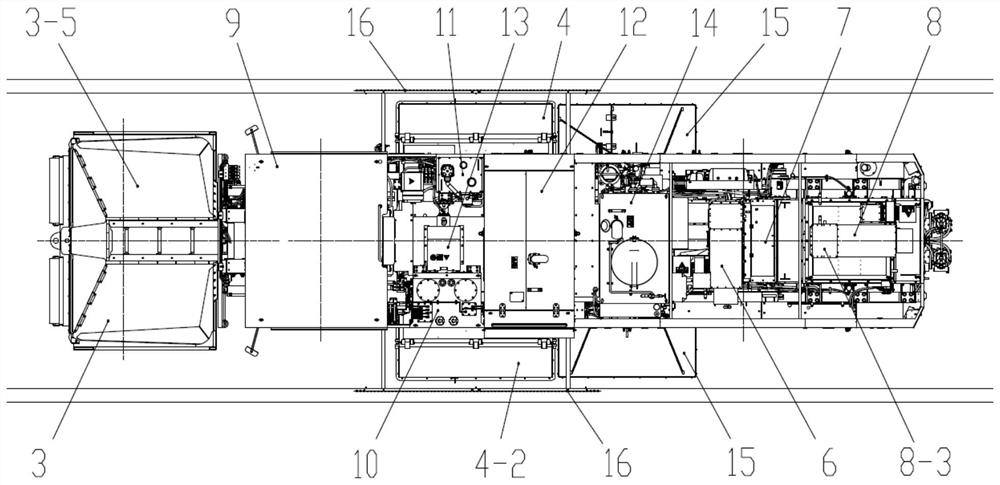

[0028] Such as Figure 1 to Figure 11 As shown, the remixer includes a frame 1 and a material receiving device 3, and the front part of the frame 1 is hingedly provided with a material receiving device 3; the material receiving device 3 includes a fixed frame 3-1, a lifting frame 3-2, and a hopper lifting cylinder 3-3, hopper luffing cylinder 3-4, hopper 3-5, hopper support beam 3-6, hopper steering cylinder 3-7;

[0029] The two ends of the hopper support beam 3-6 are respectively fixed with the hopper support wheel 3-8, and the hopper support wheel 3-8 is connected with the hopper support beam 3-6 through the hopper steering cylinder 3-7; the upper part of the hopper support beam 3-6 is fixed Lifting frame 3-2 is set, two hoppers 3-5 are hinged respectively on the horizontal section of lifting frame 3-2, the vertical section of lifting frame 3-2 is sleeved in fixed frame 3-1, the vertical section of lifting frame 3-2 A hopper lifting oil cylinder 3-3 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com