Intelligent light swing arm type crane

A swing arm and crane technology, which is applied to cranes and other directions, can solve the problems of normal production hazards, complex structure of cantilever cranes, and the failure of early warning of cranes, etc., to achieve the effect of improving operation adaptability, simple structure, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

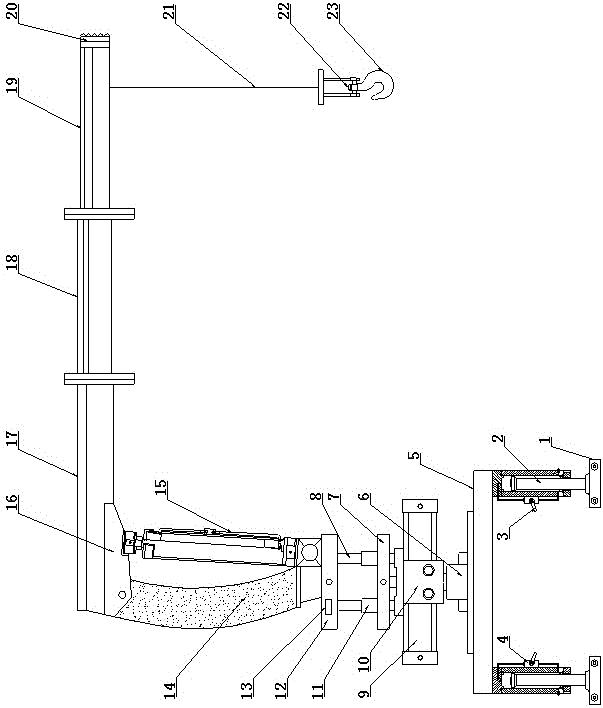

[0017] Such as figure 1 with figure 2 As shown, an intelligent light-duty swing arm crane includes a base 1, the upper end of the base 1 is connected with a hydraulic leg 2, and the inner side of the middle part of the hydraulic leg 2 is provided with a two-way lock 3, and the A handle 4 is provided on the two-way lock, four sets of the hydraulic outrigger 2 and the base 1 are provided, and a crossbeam 5 is respectively connected to the upper side of each two sets of the hydraulic outrigger 2 and the base 1, and the crossbeam 5 The upper side of the fixed seat 6 is connected with a fixed seat 6, and the upper end of the fixed seat 6 is connected with a rotating disk 10, and the left and right ends of the rotating disk 10 are connected with a fixed frame 9, and the upper end of the fixed frame 9 is connected with a Connect the chassis 7, the left and right ends of the upper side of the connecting chassis 7 are connected with a hydraulic cylinder 11, the upper end of the hydra...

Embodiment 2

[0020] Such as figure 1 with figure 2 As shown, an intelligent light-duty swing arm crane includes a base 1, the upper end of the base 1 is connected with a hydraulic leg 2, and the inner side of the middle part of the hydraulic leg 2 is provided with a two-way lock 3, and the A handle 4 is provided on the two-way lock, four sets of the hydraulic outrigger 2 and the base 1 are provided, and a crossbeam 5 is respectively connected to the upper side of each two sets of the hydraulic outrigger 2 and the base 1, and the crossbeam 5 The upper side of the fixed seat 6 is connected with a fixed seat 6, and the upper end of the fixed seat 6 is connected with a rotating disk 10, and the left and right ends of the rotating disk 10 are connected with a fixed frame 9, and the upper end of the fixed frame 9 is connected with a Connect the chassis 7, the left and right ends of the upper side of the connecting chassis 7 are connected with a hydraulic cylinder 11, the upper end of the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com