Multi-oil-cylinder lifting and rotation integrated type ocean hydraulic workover rig

An integrated, workover rig technology, applied to drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of high manufacturing, transportation, and installation costs, low integration of rotating function modules, and inability to enter the site for operations. It achieves the effect of convenient operation, improved rotating operation efficiency and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

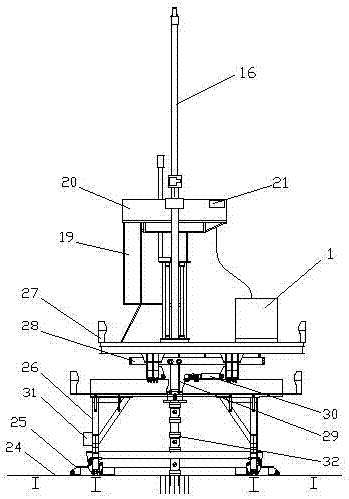

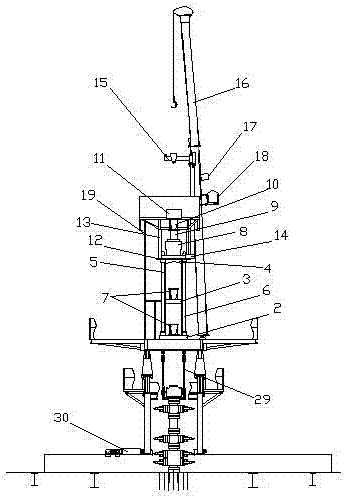

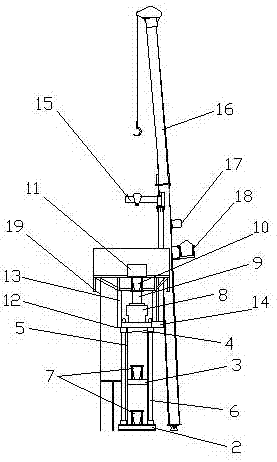

[0030] In order to further fully disclose the technical solution of the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0031] See attached Figure 1-5 , hydraulic power unit 1 ( figure 1 , figure 2 ) as a whole in the form of a closed or semi-closed skid frame is integrated and installed on the deck surface of the sliding upper base 27. It is driven by a one-inlet and four-outlet transfer case with pumps, which provide power for four sets of vane pumps respectively, and a set of triple vane pumps for power. The oil is supplied to the hydraulic tongs, radiator motor and auxiliary oil circuit; a set of triple vane pumps supplies oil to the balance winch and slips and other control systems; the remaining two sets of double vane pumps supply oil to the lifting cylinder of the lifting module.

[0032] lift module ( figure 1 , figure 2 and image 3) includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com