A front outrigger structure of a highway bridge erection lifting device

A technology of lifting equipment and front outriggers, which is applied in the field of front outrigger structures, can solve problems such as uneven infrastructure, complex front outrigger structures, and unstable operation, and achieve high construction efficiency, improved operation adaptability, The effect of improving the lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

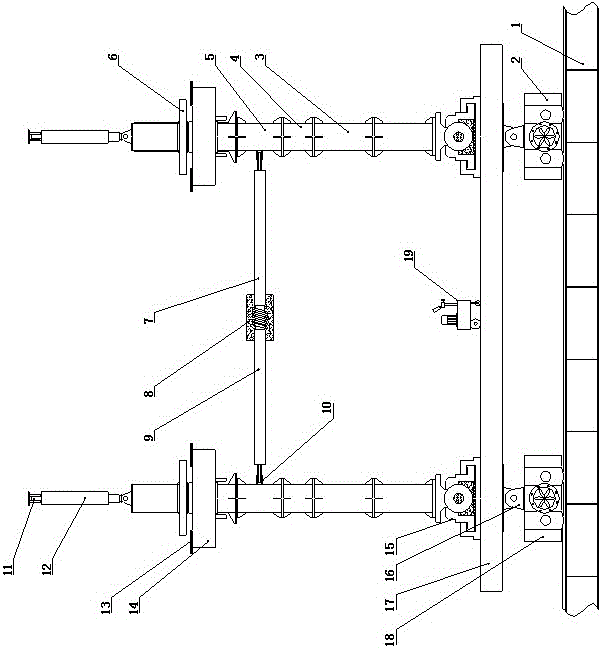

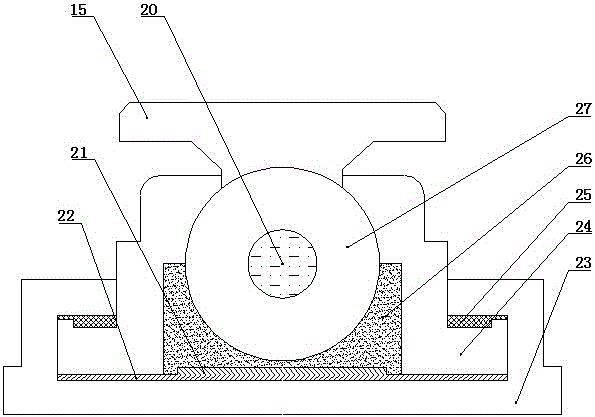

[0015] like figure 1 and figure 2 As shown, a front outrigger structure of a highway bridge lifting equipment, which includes a traversing track 1, and the left and right parts of the upper side of the traversing track 1 are connected with a driven wheel box 18 and a driving wheel box 2 in sequence. , the upper ends of the driving wheel box 2 and the driven wheel box 18 are connected with a saddle structure 16, the upper end of the saddle structure 16 is connected with a crossbeam 17, and the left and right sides of the upper end of the crossbeam 17 are connected with rotating The support 15, the middle part of the upper end of the beam 17 is provided with an oil pump 19, the upper end of the rotating support 15 is connected with a long standard section 3, and the upper end of the long standard section 3 is connected with a short standard section 4, The upper end of the short standard section 4 is connected with the middle standard section 5, and the inner side of the middle...

Embodiment 2

[0018] like figure 1 and figure 2 As shown, a front outrigger structure of a highway bridge lifting equipment, which includes a traversing track 1, and the left and right parts of the upper side of the traversing track 1 are connected with a driven wheel box 18 and a driving wheel box 2 in sequence. , the upper ends of the driving wheel box 2 and the driven wheel box 18 are connected with a saddle structure 16, the upper end of the saddle structure 16 is connected with a crossbeam 17, and the left and right sides of the upper end of the crossbeam 17 are connected with rotating The support 15, the middle part of the upper end of the beam 17 is provided with an oil pump 19, the upper end of the rotating support 15 is connected with a long standard section 3, and the upper end of the long standard section 3 is connected with a short standard section 4, The upper end of the short standard section 4 is connected with the middle standard section 5, and the inner side of the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com