Working device of wheeled dozer

A technology of working device and bulldozer, which is applied in the direction of earthmoving machine/shovel, construction, etc., can solve the problems of inability to level the working surface, inability to adjust the cutting angle of the blade, and without installing a leveling device, etc., to improve the overall performance of the machine. The effect of work adaptability, improving the working efficiency of the whole machine, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

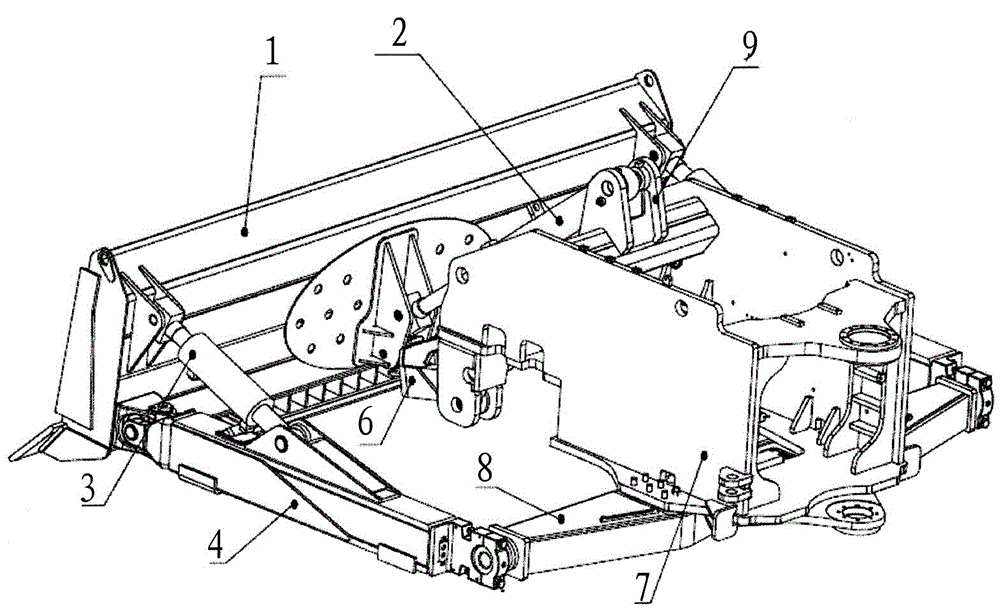

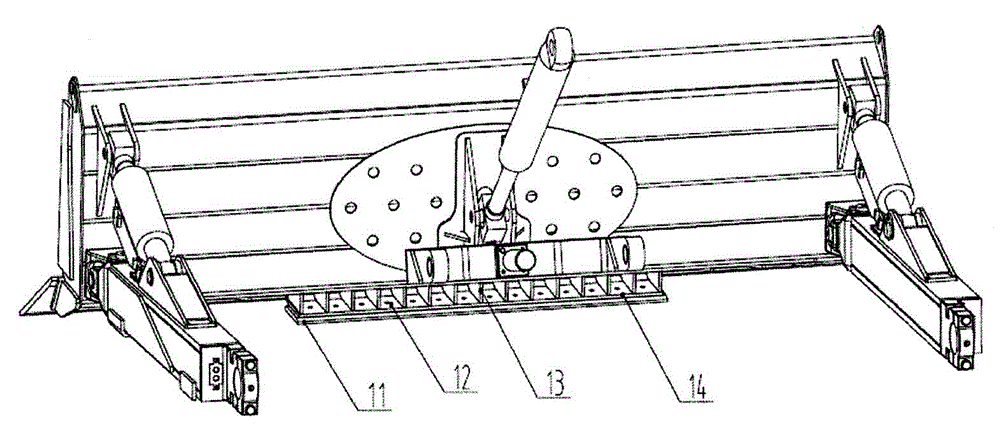

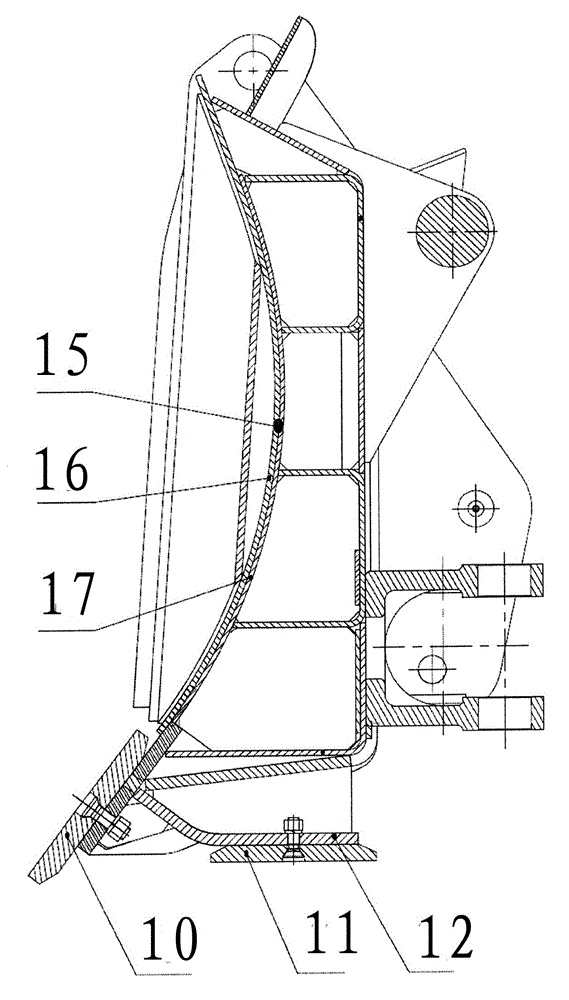

[0023] Such as figure 1 , 2 As shown, the tire-type bulldozer working device of the present invention comprises a shovel (1), and the boom (4) combined with the shovel (1) both sides in a hinged manner is connected to the shovel (1) in a articulated manner. ) and the tilting forward oil cylinder (3) between the boom (4), and the tripod (6) and the lifting cylinder (2) combined with the middle part of the blade (1) through hinged mode respectively; the boom The front end of (4) is respectively hinged with the blade (1) through a ball hinge, and the rear end is hinged with the front frame (7) push beam (8) through a ball hinge; in the blade (1) ) below and at the rear of the cutting edge of the blade are provided with a leveling device (11); the joint end of the side tilting forward oil cylinder (3) and the blade (1) is hinged through a ball joint, and the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com