An industrial double delta parallel robot structure and control system

A robot and industrial technology, applied in the field of dual Delta parallel robot mechanism and control system, can solve the problems of high cost, low efficiency, small working space, etc., and achieve the effect of strong operation adaptability and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

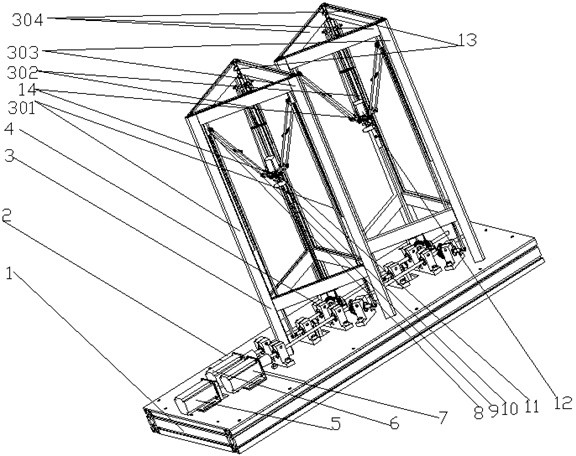

[0024] An industrial dual-Delta parallel robot structure and control system uses two Delta parallel robots connected in series to complete the same work simultaneously under the action of the STC single-chip microcomputer control system to improve the working efficiency of the system.

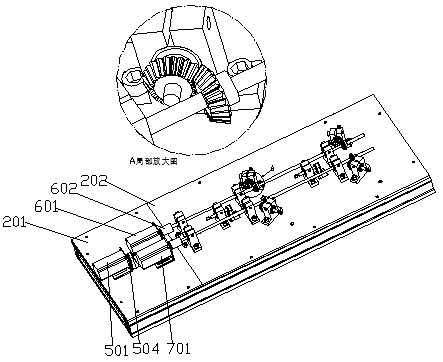

[0025] combine figure 1 , an industrial double Delta parallel robot structure and control system, mainly composed of aluminum profile base (1) and support base plate (2), aluminum profile frame (3), bearing and bearing seat (4), first kinematic chain ( 5), the second kinematic chain (6), the third kinematic chain (7), the guide rail slider assembly (8), the fisheye ball head bearing assembly (9), the parallel arm lever (10), the actuator fixing part (11) , actuator (12), limit switch (13), photoelectric switch (14), and control system.

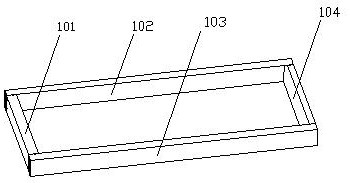

[0026] combine figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , an industrial dual-Delta parallel robot structure and control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com